Needs Pictures: 0

Needs Pictures: 0

Results 1 to 15 of 20

Thread: Clamping jig - Thoughts please!

-

23rd July 2023, 08:57 PM #1

Clamping jig - Thoughts please!

Clamping jig - Thoughts please!

I've just finished gluing up a batch of 4 boxes and decided enough is enough! Sick of stuffing about with the standard offerings of clamping arrangements . . . tried them all and settled on 4-way quick clamps but I've had my fill of them now too because you still have to muck about trying to keep the box square! I like the idea of the squaring jig Mr Crawford uses but then you're still messing with F-clamps or the like and I really just want something fully independent.

Designed this to be made out of 16mm MDF but if I actually make it, some of the parts will probably end up substituted by steel or aluminium. It should work for mitred boxes as well as fingerjoint/dovetail boxes so the spacers (in red) can be slid along to make space for the 'tail ends' to push through freely, or removed when clamping mitred boxes. I tape and fold my mitred boxes so it's mainly about keeping them square rather than applying a lot of pressure.

I'm not trying to crush the boxes, just push the glue out of the joins, so I expect I will be able to just push the side-stops up against the box and lock them in place, but have considered including a 'cam' arrangement to give box joints and extra nudge - probably 1mm movement at most.

The next step would be to place the corner clamp in place, poke the rods through into the side-stops, and firm things up with quick-nuts. Tossed up a few other ideas for tightening this part but most of them would be as fiddly as individual clamps so I would be happy to hear any other suggestions.

What I'm looking for from you lot is whether you think it will work or not, and if you can see anything I can do to improve it before I start mangling my MDF collection?!?!?!

-

23rd July 2023 08:57 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

23rd July 2023, 09:10 PM #2

Member

Member

- Join Date

- Feb 2023

- Location

- Finger Lakes Area, Central New York State, USA

- Age

- 69

- Posts

- 50

Have a look at these clamps. I bought them years ago when I was building wall hung display cases.

They are a little fussy getting them around what you are clamping but they work great. The cases we built were 30 inches tall by 48 wide inches x 4 inches deep. The clamps were great at squaring up the case and they can apply tons of force.

Here is a link https://www.amazon.com/MLCS-9012-Woo.../dp/B000FNKXIG.

There are many cheaper versions but of this style clamp but these are the gold standard.

Here is a less expensive example https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

calabrese55

-

24th July 2023, 07:10 AM #3

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2015

- Location

- Brisbane

- Posts

- 1,148

I've been using band clamps for years, never seen anything cheaper or easier. I have a dozen of the Carbatec variety and just last week bought 4 of the Pony Gorgenson from Timbercon and they are next level better.

-

24th July 2023, 10:29 AM #4

Can't vouch for the functionality of your jig, but it sure looks impressive.

Dallas

-

24th July 2023, 10:34 AM #5

I have tried the 'good' brand of bandclamps and some of the cheapies and don't like any of them in use . . . and they don't address the squareness issue. Size/capacity is of no importance to me as this is only for normal sized boxes and anything bigger is usually a one-of and not an issue to clamp with my 4-way quick clamps. Thanks for the suggestions.

-

24th July 2023, 10:50 AM #6

Vern,

The concept seems pretty good for clamping one "special" box.

The biggest disadvantages to me are that it will occupy a fair bit of space and that you will only be able to do one box at a time. Most box makers that I've followed seem to batch their production for efficiency.

I prefer the simple corner cauls with band clamps and a large F clamp across the diagonal to ease in the longest diagonal to square the box frame / carcass. I've seen images of a corner caul (to be used with band clamps) that is raised above the box side height top and bottom and has provision to take a length of all thread on the diagonal to replace juggling an F clamp.

I've used the plain old "Grunt" brand "25mm x 2m Pull Tie Down Strap" from the big green shed with good success. I like multi-function uses plus I'm trying not to "acquire" jigs etc. If the joinery is good, you don't require a lot of clamping force, and I find I can apply enough to do the job. At times if I require a bit of extra persuasion I tie the tail of the strap to a dowel as a T-handle.

I'm only a box maker out of necessity, to store things in, not a pretty box maker. I guess it really gets down to how many you make and how often.

Mobyturns

I guess it really gets down to how many you make and how often.

Mobyturns

In An Instant Your Life CanChange Forever

-

24th July 2023, 12:16 PM #7

The one I've drawn is 600x600x140 so I have room for it when not in use, and one at a time is the way I glue my boxes up anyway. I only do batches of say 4 to 8 at a time so it is no problem finding something else to do for an hour while one dries.

I've tried the other methods you mentioned, including the tie-downs, and still believe there has to be a better way. I think I'll go ahead and make it anyway and see how it goes - can't be any worse than the other methods . Too blurry cold to even open the shed today so I can still do some thinking on it yet.

. Too blurry cold to even open the shed today so I can still do some thinking on it yet.

-

24th July 2023, 02:34 PM #8

Bit cool here in Brownsville this morning too.

Have you seen the Gifkins frame clamping jig - gifkins.com.au/wp-content/uploads/2014/08/02-clamping-frame.pdf

Perhaps a modification of it's clamping sides to suit a box may work.

I've considered using cam clamps - Rockler Cam Clamps - 1/4" Thread - 2 Pack | Carbatec with a length of all thread (as the clamps) and a frame similar to your concept but have never got around to it. Don't make enough boxes and have too many distractions now.Mobyturns

In An Instant Your Life CanChange Forever

-

24th July 2023, 02:48 PM #9

Senior Member

Senior Member

- Join Date

- Feb 2023

- Location

- Sydney

- Posts

- 107

I like the design.

Just a random thought, but could you drill holes or slots in the base MDF and use small ratcheting ("quick") clamps to hold the sides down to the jig base. This would prevent twisting to the box.

-

24th July 2023, 05:37 PM #10

Twisting is one aspect that has had me concerned but I think I'll try it as is first. The Gifkins rig that Mobyturns mentioned in the previous post uses G clamps to hold the frame down but I reckon if it looks like being a problem I'll set up a hold-down similar to those I use on my tablesaw sled. If my joinery is accurate enough, I shouldn't have to worry about the box twisting as it is clamped up

-

24th July 2023, 05:54 PM #11

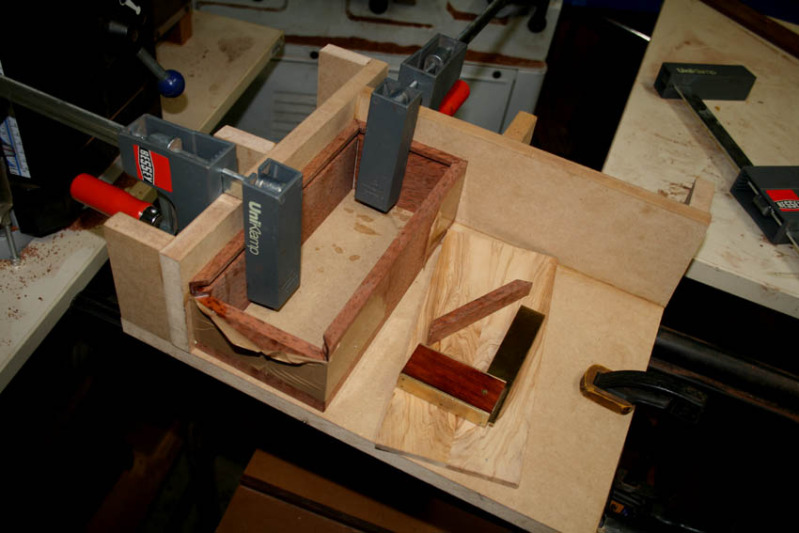

TTIT, I posted this several years ago ...

'

'

In my case, I did complete a workshop with Andrew Crawford, and subsequently made a few of these fixtures in different sizes. Useful for mitred cases as well.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

25th July 2023, 10:48 AM #12

-

25th July 2023, 02:21 PM #13

Vern I use toggle clamps a lot on my table saw sleds etc. Perhaps some of the piston action horizontal throw toggle clamps mounted on a riser block and using thick cauls would work as a replacement for the F clamps.

Do a dry fit adjust the clamps for throw length etc so it becomes a simple throw a couple of levers affair.

Piston Action Toggle Clamp (mcjing.com.au)Mobyturns

In An Instant Your Life CanChange Forever

-

25th July 2023, 06:00 PM #14

One possible problem I see with using threaded rods in the way you propose is that while it'll apply pressure on the joints of the sides nearest the rods, it won't apply it equally to the joints alongside the fence.

Unequal pressures = unequal squeeze-out.

You've stated that you dislike band-clamps, but perhaps you could have spaced gaps in the fences to allow a band clamp to pass through the fences and, in effect, tension everything equally while the fences still keep things square? Although I think that just the masking tape should be more than sufficient clamping.

(My first thought was c-channels in the base with sliding adjustable clamps, but that's really no different to using f-clamps in the first place. )

)

- Andy Mc

-

25th July 2023, 06:05 PM #15

I use this fixture (or, rather, a larger version) to glue up drawers. The last thing that you want to do is add pressures/stresses which will affect the squareness of joinery. All those clamps (they are "parallel" clamps) do is hold the sides flat against the fixture walls. The joinery is held tightly by the packing tape.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Clamping Help Needed! Irregular shape clamping

By retrowoodwork in forum GLUEReplies: 8Last Post: 6th April 2015, 06:43 PM -

Clamping advice?

By BoomerangInfo in forum CNC MachinesReplies: 12Last Post: 28th January 2012, 09:30 PM -

Clamping Solution

By Scribbly Gum in forum HAND TOOLS - UNPOWEREDReplies: 7Last Post: 24th December 2011, 10:19 PM -

clamping ?

By Tonyz in forum WOODCARVING AND SCULPTUREReplies: 5Last Post: 7th November 2005, 07:40 AM -

clamping

By Shaty40 in forum WOODWORK - GENERALReplies: 9Last Post: 26th December 2004, 02:52 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote

Your original post might have been what cemented the idea in my scone. Just have to bypass the F-clamps.

Your original post might have been what cemented the idea in my scone. Just have to bypass the F-clamps.