Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 18

Thread: dt

-

10th June 2008, 08:36 PM #1

dt

dt

Started my new ? I don't think it would be classed as a box.

Went through the offcuts and found this piece of Br.Mahogany 1mtr by 100mm by 5 mm thick. It has been lying around for perhaps 3 years, and was the waste piece from a 25mm thick board off the bandsaw

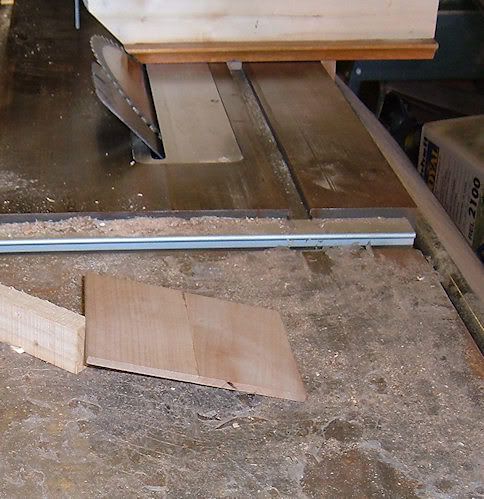

So put it through the table saw to reduce width and recut twice at the same fence setting so that both pieces were the same width.

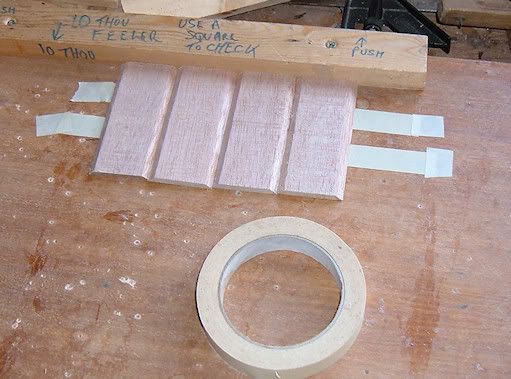

Held it down with this. (its only 5mm thick)

Then put it through the tablesaw again but with the blade set to 45% and held down with this temporary clamp and block.

Hand cut to 100mm lengths and set up ready for gluing. I have found it pays to hold the masking tape down with a small piece of masking tape each end whilst preparing to glue and fold up to stop the tape winding back on its self.

First part glued up and three more to go.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

10th June 2008 08:36 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

10th June 2008, 08:51 PM #2

Looking good Woody, a pen box maybe

Cheers

Cheers

DJ

ADMIN

-

10th June 2008, 10:52 PM #3

Interesting to see what this one turns out to be.

Looking good. Nice timber.

Reality is no background music.

Looking good. Nice timber.

Reality is no background music.

Cheers John

-

11th June 2008, 02:32 PM #4

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Feb 2007

- Location

- Adelaide

- Posts

- 595

Good idea with the masking tape Jow, I have got in tangles with it wrapping around in the past.

I often use duct tape which seems to give me a bit more "clamping" pressure.

One of my biggest problems with this wrap around mitering method is the amount of glue squeeze out I get on the inside of the box. I am a bit scared of not putting enough glue on the end grains of the mitres and so maybe I overdo it, but I try to put most glue where it should be squeezed out on the outside, but the glue usually refuses to obey me.

How do you tackly that?

-

11th June 2008, 05:38 PM #5

The glue I usually clean out with a chisel at a later date, if you mess around cleaning up at the early stages you lose valuable maturing time and run the risk of displacing parts etc. but I do have a wet rag around and clean up outside faces.

Unfortunately I am going to have to remake this first piece, owing to its unusual proportions it has fallen out of square when the glue was allowed to set.

I've also got my eye on some other timber laying around that has a harder surface and could be more suitable.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

12th June 2008, 12:20 AM #6

Troublesome day, first I dropped the bread cutting knife (breakfast time) then the jam spoon fell out of my hand and I got raspberry jam over my trousers, the slice of bread and jam fell out of my hand and landed upside down, other things happened but not coming to mind as I type.

So I went out to the workshop and decided that the first timber piece glued up was a failure (out of square owing to the piece slumping whilst awaiting glue to set). So I smashed down on it with my clenched fist and the glue must be good because the joins did not break apart but the wood split away from the glue line. So its true when they say the adhesive is stronger than timber.

So located some more offcuts, iroko and sycamore, and prepared and cut timber as per the first piece yesterday, and I have finished up 10mm short on the width of each piece.

Even the new timbers didn't finish up even measurements across their widths so I taped them up and put them through the thicknesser.

The Australians say their ladies are having a bad hair day when things are not running smoothly but I don’t know what expression to use in this instance but Bugger

So fortunately I like contrasting effects on my timber projects so that piece of sycamore is going to come in handy but even that has not got a straight edge.

The temperature is over 30c in the workshop so calling it a day.

At least the sun is still shinning and the flowers look good, anyone beat that for colour.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

12th June 2008, 08:57 AM #7

I love this...

You find some scrap and play with it not really being sure what's gonna come out of it. It doesn't work out so you go digging through the rest of your stock to remake it, 'cos dammit I'm gonna make whatever the heck it was....

so you go digging through the rest of your stock to remake it, 'cos dammit I'm gonna make whatever the heck it was....

Very interested in seeing how it goes...

Cheers,

Dave...but together with the coffee civility flowed back into him

Patrick O'Brian, Treason's Harbour

-

12th June 2008, 09:49 AM #8

Loving this thread, jow. We've all been there, mate. Hope the hand is OK.

Those are my principles, and if you don't like them . . . well, I have others.

Those are my principles, and if you don't like them . . . well, I have others.

-

12th June 2008, 05:53 PM #9

I must confess I went back in the workshop in the evening because I heard the lady talking about shopping today.

So I glued up some pieces as per picture below and thought I have spent all day and only got back to this position that had been obtained 24 hours earlier. I have got a lot more timber prepared though.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

13th June 2008, 06:24 PM #10

I have now got two sets glued up and they are reasonably true this time.

after glue had set picture.

Bindings off and they will hopefully clean up when put through the thicknesser and they will be thinned down a bit.

If I was doing this operation again I would prepare timber to thicker dimensions and after gluing up thin down that way instead of using 7mm thick timber.

I am going to try and reduce thickness of each section down to 3mm woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

15th June 2008, 06:07 PM #11

Project delayed owing to workspace congestion, I had to empty, select and dispose and retain timber from scrap boxes because I was bumping into scrap containers all over the shop.

Managed to part with a couple of cubic feet.

Cleaned up the two laminated sections however in the thicknesser and reduced to four pieces, random sized to length.

Found a nice scrap piece of sycamore that was 22mm thick and this was resawn and produced two pieces cleaned up at 9.4mm.

This section might start to give a clue to the eventual use of this workpiece, yes it’s the start of a box, made in my usual fashion, mitred corners and glued up as per the knowledge gained on one of those Australian trips.

Carcass glued up and now making a decision whether to fit a drawer to the front or insert a container section under.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

16th June 2008, 12:13 AM #12

I agree with zenwood: This thread build very amusing. The plain determination to make something out of this scrap is as much fun to watch as the build. I'm interested to see what catastrophe happens next and it gets turned into.

-

16th June 2008, 04:00 AM #13

Decided to try and fit another box inside of top piece, (perhaps a drawer next time)

So my pieces of scrap sycamore are rapidly decreasing, found these three pieces.

Ripped them to 75 mm widths.

Thicknessed them to around 7mm even the 6" lengths, fed them through the thicknesser one after the other on the same track (I leave a 3mm batten peramently at the inside of the thicknesser to stop any small pieces jamming at the side plate)

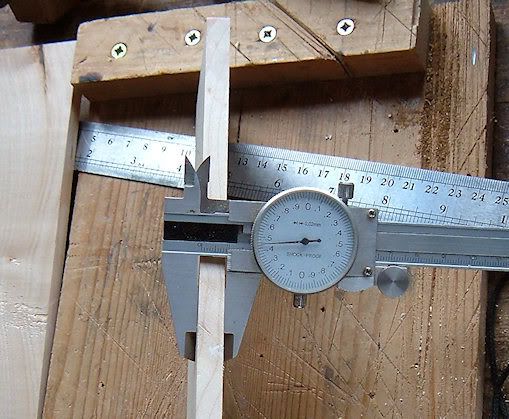

Then put one mitre corner to each piece, measured the inside of the box with calipers and all four dimensions came withing 110 to 110.4mm, so put the stop block set at 110mm and then with a few recuts got a dry fit as per this picture.

Lined the inside with cling film to stop any adhesive wandering where not wanted.

And glued insitu

Waited a couple of hours (in stress) wondering if the lower box would pull out, and it did.

.

.

However I might fit a widget so that it can be pushed out at a later date in case atmospherics effect its very close fit.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

17th June 2008, 04:17 AM #14

Looking through my scrap pieces I came across this waste piece of sycamore, at least 4 years old, and its perfect, it will make 4 sides with less than 3mm of waste at the final cut. I remember saying to myself why hang on to this bit.

Decided to put corner splines on each piece, this item could get a lot of handling over the years. so used a jig I made last year as per pic.

And machined up these.

Over the last 12 months Australian forum members have sent me samples of Australian hardwood for use on my boxes and I am pleased to show gifts from Woodborer, and Jackson of Bundeberg.

I put this piece to the bandsaw and cut a 3.2mm thick slice and then divided it in two.

Glued into position thus.

And when the glue had set I used a japanese saw without any set to cut flush with the boxes.

I digress, I have found some more scrap boxes so my stock of hardwood scraps will continue for some time.

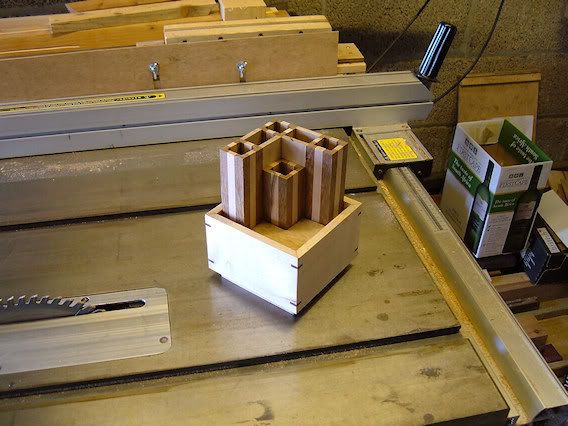

Back to the job in hand, I cut a supporting piece for the tubes (square)

And glued all the storage holders in place as per this picture.

It will now become evident that this is to become a pen holder with storage below, (There might be a secret compartment created by the lower box)woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

17th June 2008, 06:11 PM #15

Out of the clamps.

A couple of Australian pen gifts , Neil of Ubeaut and Woodborer of Victoria.

A trial run in their cases.

I am thinking of adding a beading around top edge using some Red Gum and also beading/bottom edge to base that might hide the second box.

A velvet lining to the table top must soften the raw top.

This project takes me back 60 years when I had a mecanno set and after making the usual set pieces we then started making those Heath Robinson contraptions but I was always told I wasn't to bend any pieces.

If anyone wants to let me have a handmade pen or pencil for the stand I naturally would cover expenses.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

Reply With Quote

Reply With Quote