Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 74

Thread: A type of lazy susan

-

2nd September 2007, 05:40 PM #1

A type of lazy susan

A type of lazy susan

http://www.woodworkforums.ubeaut.com...ad.php?t=55591

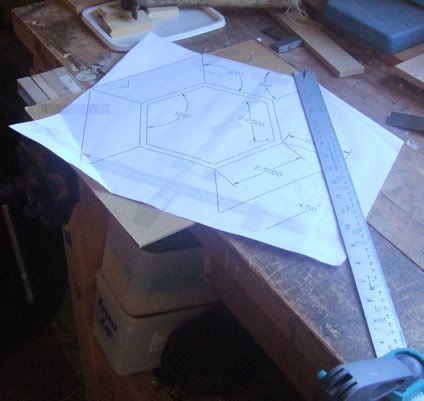

I had help form forum members who kindly supplied a working drawing (using their cad program and also some trig experts.) which I blew up in PSP X1 and made a full sized poster.

So am going to attempt a seven box project using a different species of timber for each section. I will most probably keep the setup as a fixed system to avoid turning it into a mobile feature and thus avoid balance problems. Also not going to glue each box until the outer ring has been completed incase cutting accuracy does not come at 100%(which I think would be very unlikely)woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

2nd September 2007 05:40 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

2nd September 2007, 05:47 PM #2

I look forward to seeing how this progresses. By the way, if anyone needs help with some plans, let me know as I am an Architect and would be happy to assist anyone needing box plans.

http://www.woodcraftedspoons.com.au

Visit my spoon making tutorial...still in progress...

Spoons...better than chopsticks but harder to make.

-

2nd September 2007, 05:53 PM #3

Thanks Spoonman, I have said before that the internet has brought some good things to this modern world, such has your reply above.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

3rd September 2007, 02:15 AM #4

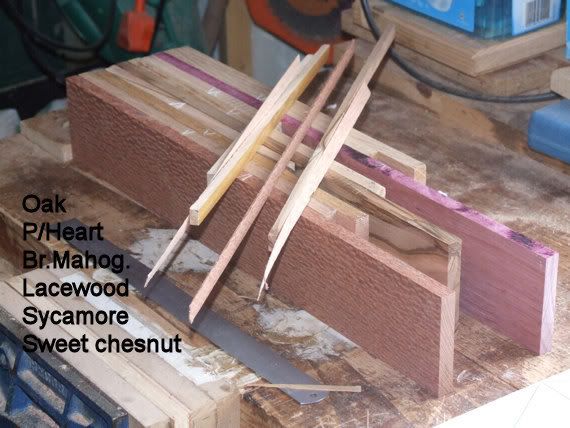

Spent the day preparing timber for the six outer boxes and pleased to say that all finished up at 12mm thick and 74mm wide, various lengths but should be enough I hope if there are no mishaps.

The Shelves shown were from our childrens bedrooms made in 1970 and have been stored in the loft the last 23 years. They would have been made by hand (perhaps a black & decker portable clip on circular saw may have been around then) the joints shown were through tenons and wedged.

The last picture shows timbers finished with a few slivers laying on top that are 0.5mm thick after coming of the Triton workcentre. I was thinking I might purchase a tablesaw this week at the Yandles wood show, but how could I improve on that ripping.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

3rd September 2007, 03:31 AM #5

Beautiful selection of timbers there.....by the way, where did you get the purple heart and brazillian mahogany.....as, correct me if I'm mistaken, but I'm pretty sure both of those timbers are endangered species now and are quite hard to get...at least here in Melbourne. Look forward to seeing this project progress. I'm also happy to see you recycling some timber from past furniture....I do the same where I can. Especially on hard rubbish collection days, people throw away unbelievable timber. I just missed grabbing a blackwood solid desk someone was throwing away, someone else just beat me to it.

http://www.woodcraftedspoons.com.au

Visit my spoon making tutorial...still in progress...

Spoons...better than chopsticks but harder to make.

-

3rd September 2007, 05:25 PM #6

Thank you Spoonman for your comments.

The Br. Mahogany I purchased (30 mtrs. of 8"x1") over 5 years ago from a builders merchant, they said at the time it was a cancelled contract and I got a bargain. (around 6 mtrs. left on my shelf), There seems tobe a fair amount of Purple heart here in the U.K. at the moment.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

3rd September 2007, 07:18 PM #7

-

3rd September 2007, 07:23 PM #8

Day off today, I've reached the three score years and ten.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

3rd September 2007, 08:37 PM #9

-

4th September 2007, 10:55 PM #10

Had a little rant on another forum, then went and helped the trouble and strife getting ready for the autumn cleanup in the garden.

And then did a dummy run on the boxes using some software battens cut to size fitting the template as shewn below.

Its not proving to be easy because very precise measures are required taking into account angles.

So can anyone out there give me some directions or tips which way they would go?woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

4th September 2007, 10:59 PM #11

Does each segment have to be a discrete box?

- Andy Mc

-

4th September 2007, 11:04 PM #12

It might have to come to that.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

4th September 2007, 11:21 PM #13

It's just I was thinking you could hot-melt a couple of strips to a sacrificial piece of ply or MDF at the right spacing, and then you could cut both the matching inside and outside pieces in one pass. Alternating the direction of the cuts would economise on the wood.

Attachment 54868

With the MDF/ply still holding them in position, you could fit the sides (spokes?) to complete each segment and later remove the MDF/ply to fasten a base.

Do you follow what I mean? You'd still need to be as accurate as possible, but it reduces the number of cuts, so makes for less chances to screw up... Thinking on it, you might need to fit a block here'n'there between the sides to keep 'em squared to the base, but it's still doable. I think. It's not something I've ever tried...

- Andy Mc

-

4th September 2007, 11:27 PM #14

Thats sounds great advice, I'd been thinking along the lines of something sacrificial.

Anymore bids? woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

5th September 2007, 03:59 AM #15

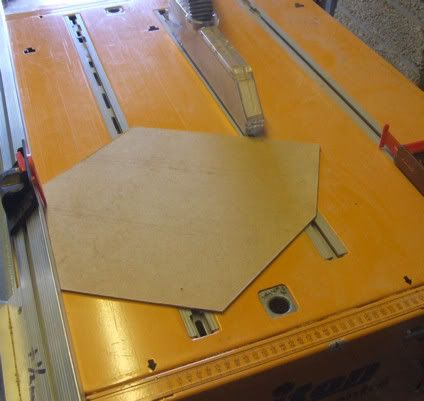

Using the paper pattern I made from the computer I have cut a hardboard template and going to attempt to stick box sides with a temporary type of glue to the hardboard and gluing up the sides with pva and superglue at the same time.

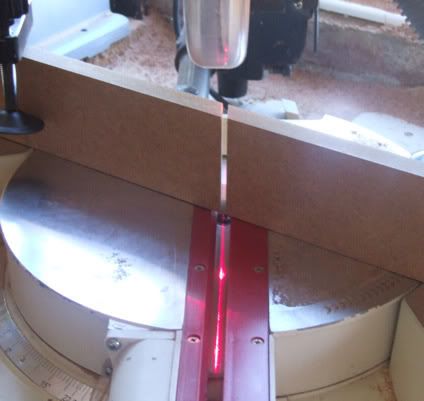

Nailed an old ruler to the bench and used a Stanley knife to cut some of the hardboard to shape. Nailed the ruler down because last year the stanley knife ran across the ruler and my thumbnail and it needed superglue to stick the thumb tip back on.

Cut the template out as per photographs below and had a bonus, I got 4 60x30x90 triangles (forgotten what sort of triangles they are called now)

Put a fence with a 30% cutting line ready to use on box sides.

But still not commited if someone advises me a different way later this evening.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

Similar Threads

-

Sturdee's Lazy Susan

By Sturdee in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 4Last Post: 16th April 2007, 04:26 AM -

lazy susan finally finished

By paul collins in forum WOODWORK PICSReplies: 3Last Post: 9th January 2007, 03:31 PM -

Lazy Susan Finishing

By Happy Chappy in forum WOODTURNING - GENERALReplies: 10Last Post: 18th July 2006, 04:28 PM -

Lazy Susan

By stu_g18 in forum WOODWORK - GENERALReplies: 11Last Post: 24th May 2005, 08:41 PM -

lazy susan

By Agro in forum TIMBERReplies: 2Last Post: 28th February 2005, 07:39 PM

Reply With Quote

Reply With Quote