Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 21

Thread: The cheap fret slot saw set up

-

2nd May 2010, 10:04 PM #1

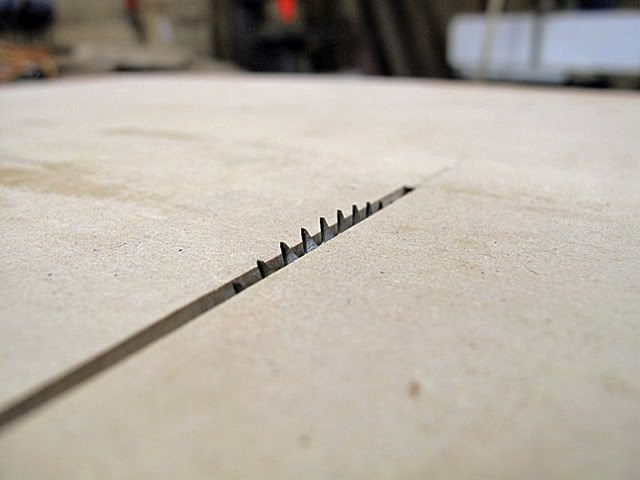

The cheap fret slot saw set up

The cheap fret slot saw set up

Floody and Andy have been hanging for pics of this, so here we go.

First an overview.

This is for those that want the ability to slot fretboards quickly, but don't have a dedicated Droppy (SCMS) or a saw bench.

I got this motor and assembly from Bunnings for around $100

This machine matches the Stew-mac fret saw arbor of 5/8"

Basically threw everything away but the motor and cradle. It is marketed as a table saw but really wasn't worth hanging onto the top. Not if accuracy was to be had.

The MDF box was made to size and the sliding top uses Ball bearing

drawer sliders. There is also an index pin mounted in the Jarrah

slide fence for indexing the stew-mac fret slot templates as well.

I've had this for around 12 months and find it to be a real time saver.

Set up is integral to getting accurate slots cut, and once the initial set up is

achieved , it shouldn't move at all. The bearing drawer sliders stop any sideways pivot or slop and create the perfect glide forward and back.

-

2nd May 2010 10:04 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

3rd May 2010, 01:27 AM #2

thanks for that Stu

so thats one of the small ozito or gmc saws? or is it one of the little tile cutting ones?

how do you adjust the blade to make sure it is all square to the sliding top/fence?

so your selling these in flat packs?

-

3rd May 2010, 10:12 AM #3

I like it!

-

3rd May 2010, 06:10 PM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- Dec 2008

- Location

- Bradbury

- Posts

- 1,429

-

3rd May 2010, 07:27 PM #5

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Sydney

- Posts

- 489

Thanks Stu,

That is a great set up. Can the depth of cut be adjusted easily?

Cheers,

Peter

-

3rd May 2010, 09:46 PM #6

Peter, this is set up at one depth only. To vary the slot depth , I run a

suitably sized substrate between the sliding table and the fretboard.

It would be possible to introduce a riser setup, but I'm more happy

to use a substrate and know it is perfectly tuned always.

Andy, A simple method of getting the blade parrallel with the sliders and fence is to use a mitre square against the fence and then slide the fence forward.

You want to see the square's edge against the saw's blade maintaining the same gap all along the travel distance. If this gap alters, then you've got run-out.

To state the obvious, this doesn't do fanned frets either.

-

3rd May 2010, 10:20 PM #7

This is similar to what was used and the rest thrown away.

Marketed as a table saw.

Cost was around $100 from memory at Bunno's

Possibly badged as an ozito, but the only importance was the actual bore/arbor size

to match a Stew-mac blade

Pic. is here..........https://www.woodworkforums.com/f153/s...10/#post709660

-

4th May 2010, 01:55 AM #8

hmmm

i guess i will have to build one now...

it seems like the easiest way to go about slotting, other than spending a fair amount on a mitrebox, which involves more physical activity

hmm i wonder if theres any blades like the stew mac ones, that are more... local...

so this will involve,

the saw - 100ish

slotting template - 45

blade - 80

mdf

drawer runners

index pin

fence

-

4th May 2010, 08:36 AM #9

The Stewmac blade is well worth it. The whole blade is case hardened, it'll last you a long time, you only need to keep it sharp. The downside to that is that reboring for a different size arbour is not easy . I had to do that for my SCMS and ruined a drill bit.

That setup will save you a lot of time on cutting fret slots, you'll wonder how you ever did without it.

The box looks great Stu, I feel like making myself one too now

-

5th May 2010, 05:40 PM #10

-

5th May 2010, 07:27 PM #11

Well, you already have a double sided slotting template, you only need to make an index pin for it, unless it's not the scale you need.

If you need a different scale to that one I may be able to arrange another for you, If you like.

Your local saw manufacturer can easily make that saw for you but I've priced them and it's actually cheaper to get it from stewmacs.

regards

Wal<style type="text/css">p { margin-bottom: 0.25cm; line- 120%; }</style> Only two things are infinite, the universe and human stupidity, and I'm not sure about the former. Abert_Einstein.

-

6th May 2010, 06:01 PM #12

GOLD MEMBER

GOLD MEMBER

- Join Date

- Dec 2008

- Location

- Bradbury

- Posts

- 1,429

-

6th May 2010, 08:10 PM #13

They aren't that hard to make, actually they are really easy to make.

All you need is a length of 3 mm flat aluminium, it can be 4 or 5 mm but not less than 3 mm about 10 or 15 cm longer than your fret board and between 60 -80 mm wide.

Mark your frets accurately on the flat aluminium scribing them with a razor blade or Stanley knife, then cut notches in the centre of each line down one side, I used a band saw for this and the notches ended up the width of a hacksaw blade.

You could make an index pin from a piece of hacksaw blade .

.

Aluminium is really easy to work with and if you gotta mark frets out anyway you may as well do it making a template and cut your job down in the future.

Half way down this page is where I posted mine. Post #162

page is where I posted mine. Post #162

https://www.woodworkforums.com/f98/bo...3/index11.html

regards to all

Wal<style type="text/css">p { margin-bottom: 0.25cm; line- 120%; }</style> Only two things are infinite, the universe and human stupidity, and I'm not sure about the former. Abert_Einstein.

-

6th May 2010, 09:15 PM #14

GOLD MEMBER

GOLD MEMBER

- Join Date

- Dec 2008

- Location

- Bradbury

- Posts

- 1,429

Ah i forgot about that..I remember reading it now..Ill give that a shot! Might go buy one of those little table saws from bunnings this weekend!

-

7th May 2010, 05:55 PM #15

indeed the mad professor made me a slotting template

i never got around to checking its accuracy might do that soon, but i trust wally

might do that soon, but i trust wally

Similar Threads

-

Fret press

By rdiquattro in forum MUSICAL INSTRUMENTSReplies: 17Last Post: 26th January 2010, 03:10 PM -

Need fret help

By d5ive in forum MUSICAL INSTRUMENTSReplies: 21Last Post: 7th January 2010, 09:51 PM -

Fret Saw/Dovetails

By Gil Knowles in forum HAND TOOLS - UNPOWEREDReplies: 0Last Post: 6th December 2009, 05:30 AM -

Fret Saw

By Different in forum MUSICAL INSTRUMENTSReplies: 10Last Post: 20th February 2009, 07:02 AM -

Fret slotting jig - anyone want to slot some boards?

By JupiterCreek in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 24Last Post: 20th August 2006, 04:31 PM

Cheers, Stu

Cheers, Stu

Reply With Quote

Reply With Quote