Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 69

Thread: Fret slotting saws?

-

13th March 2008, 12:19 AM #31

Using a sliding compound mitre saw would be an easier set up for sure.

The only drawback to ALL SMCS's is the fact that even though you may have set the gauge on the blade depth stop, there is still a discrepancy in how deep the blade cuts due to the pressure required in sliding the saw forwards and in turn

creating downwards pressure. Eek.........a deeper cut.

They all flex at this point unfortunately. Having said that, I'd much prefer to do that setup for myself but can't be buggered constantly taking my 12" makita scms out of my work van, change for the small kerf blade, use it, rechange the blade then back in the van for the next day's work. A dedicated unit's what I want.

-

13th March 2008 12:19 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

18th July 2008, 05:54 AM #32

New Member

New Member

- Join Date

- Jul 2008

- Location

- Portland, Oregon

- Posts

- 1

Table Saw Fretting

Table Saw Fretting

Hello folks,

This is Mark over in Portland, Oregon.

I found that having a separate fretting setup other than the primary table saw was beneficial, so I didn't have to keep making changes with the saws blade.

I looked around for an older used 8" table small and found a Craftsman 8" used in good condition for $20 US. These saws are small, light, and portable. All good. It has dual miter tracks for better fret sled control.

Set it up on it's own stand and built a dual purpose miter sled. Perfect for fretting. I use the Stewmac fret saw blade on it.

By dual, I mean my sled flips around 180 degrees to cut frets on both sides, and more. I build guitars and ukuleles, and the thickness of the fret boards can vary.

One side handles 1/4" thickness and the opposite handles a thinner ukulele fret board. Each side has a registration pin that needs to be in a specific location to match up with the proper height/location of the scale template I am using to cut the fret board.

I use this same sled design to cut my own kerfing, as long as the distance from the pin to the saw blade is what you want for your spacing, and the registration pin is small enough to fit inside of one of the saw cuts. Slice up a length of board by around 6"-12" wide, then put it on the bandsaw with a fence set up to cut the width of each kerfing strip. Each strip then goes to the router table with a quarter round bit to produce a "reverse kerfing strip".

Easy. Accurate.

Cheers.

Mark

-

24th July 2008, 11:56 PM #33

Novice

Novice

- Join Date

- Aug 2007

- Location

- Warwickshire, UK

- Posts

- 22

Hi folks

Haven't looked in here for yonks.

These powered options sound fab, although I'm just about all hand powered these days. I use the LMII jig and gents saw. Not keen on the saw, though do find it better than the (old style) Stewmac I had before.

I'm toying with trying to retooth it, as even for mandolin FBs it is a pretty high tooth count for the width of cut - may well be why it's so slow?

Thomas Flinn (Pax) in the UK make a 16tpi 'Guitar Saw' that retails at around 18 quid (GBP) - though it may need the set tweaking (cited as 21 thou.) As the new stewmac is Sheffield made, I wonder if it's one and the same?

I do have an extravagance pencilled into my future, as I have an order in with Mr Wenzloff for a pistol grip fret saw (I really don't like broomstick handles)

I envy your duty threshold - IIRC it's just 23 quid here in the UK (IOW we just about always get stung for 17.5% VAT plus (variable, seemingly at the whim of the customs agent) import duty).

Cheers

Steve

-

25th July 2008, 09:40 AM #34

This fret slotting saw thread always manages to pop back up for some reason... I'll take Stu's suggestion and post my slotting setup in this thread also to keep it all together. It'll be less complicated than to search over a couple of threads.

Warning: this is cut-copy-paste guys, so you've read all this before

I recently got a comission for a fanned fret 6'er. I figured I'd build a jig or template to help the fret slotting part and keep it for future use.

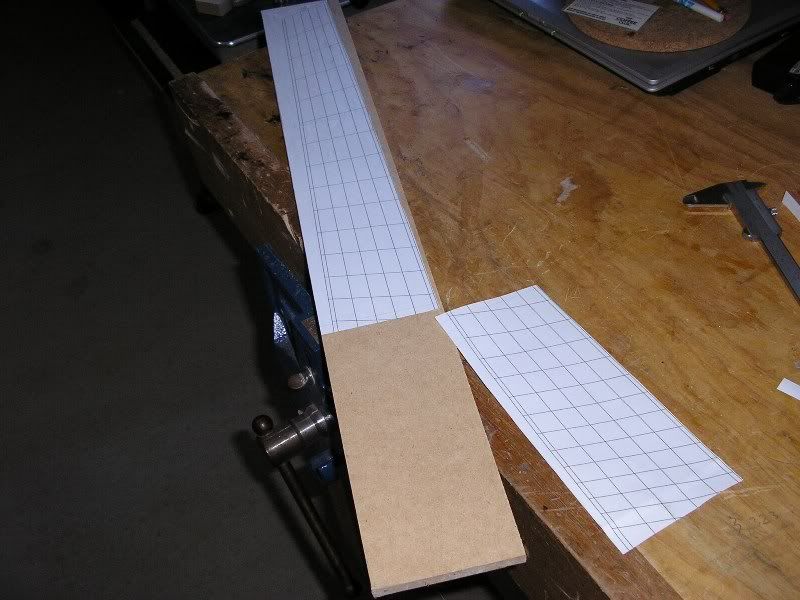

I used fretfind to draw up the fan fret spacing and printed it out as a mirror-image (i.e. lefty)

I glued that to a blank sized piece of MDF and used an adjustable square to help guide the saw as I was slotting it by hand

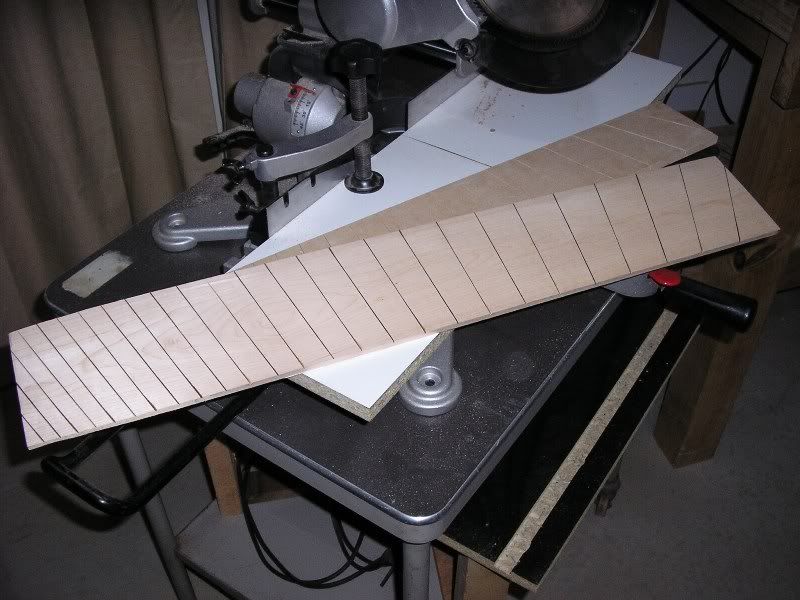

The result once the paper is ripped off and the MDF is sanded clean.

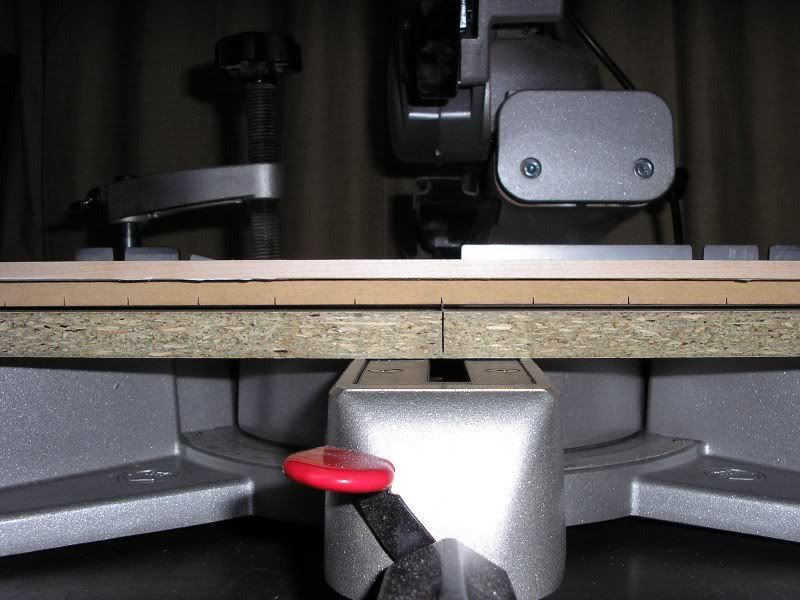

I made a makeshift table out of particle board. Using the saw I cut a small slice that's the same kerf as the slotting blade and squeezed a thin piece of metal in it. That piece of metal is the indexer of the jig.

The jig works by taping the fingerboard blank onto the back of the MDF tempalte. The template locks into place in each fret slots on the metal bar inlayed in the table. That bar is aligned with the saw blade.

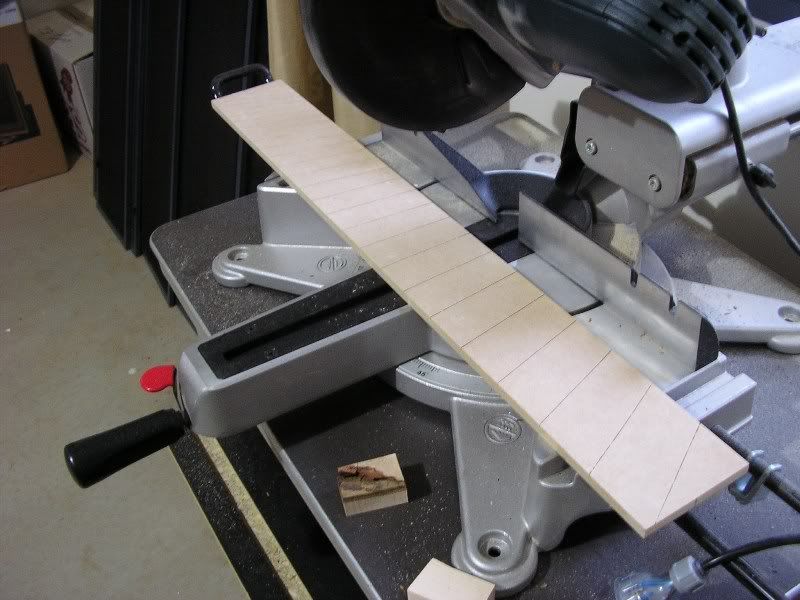

Push the template in the metal bar, slice the fret with the saw, lift off the template, move to the next position and start again until you're done. This Maple blank took less than 5 minutes to cut.

All in all, cutting the MDF template all the way to finishing the cuts on the sliding compound mitre saw took less time than it would have taken me to cut the Ebony board for this build by hand. The obvious big advantage is that its re-usable for future builds.

Right, I realise I didn't show exactly how the saw works. Since not everyone has one or knows how to use it I might as well show this at the same time.

So what we've got here is a Sliding Compound Mitre Saw, often shortened by SCMS, not to be confused with a normal mitre saw. The difference with the regular one and the SCMS is in the length of the cross-cut that you can do. A normal Mitre saw only has a tilting head that tilts down (obviously) and cuts a board in cross length. The sliding compound mitre saw also has a linear bearing assembly that let's the saw slide up and down a rail to make a longer cut.

A normal mitre saw is not suitable for this application, the more expensive SCMS is the one that should be used for this.

I've mentioned before in other threads that a cheap SCMS wouldn't be any good for this and you had to pay more than $500 for something suitable. The reason being the tolerances built into the saw. The better the sliding assembly the more the cut will be as it should be (right kerf). If you use a cheap one, the sliding assembly will likely wobble and screw up your fret slots.

So here's the pics now

The first one shows the saw in it's off position, the head is tilted up. Second one shows the head tilted down to start the cut and the third shows the sliding assembly being pulled to finish the cut. The saw has a set screw on top of it to adjust the depth that the saw will cut.

The difference between this jig and normal fret slots is just the fact you should use a makeshift table with a fence. In that fence you need to inlay an indexer, i.e.nail in a brad nail and cut its head off but leave a few mm protruding. The stewmac fretting template locks into that brad nail in the fence.

-

29th September 2008, 02:25 PM #35

Intermediate Member

Intermediate Member

- Join Date

- Sep 2008

- Location

- newcastle

- Age

- 79

- Posts

- 29

Hi fellow Im a newbie to the forum, just a short post. Have bought from both Stewmac, parts and such and from Amazon, books on how to put them together !!! fun no problem ever with customs or time frame and you can track your order easy, would love a picture/drawing of this fret slooting jig, course I'm poor a don't have one. Stewmac is overpriced for hobbyist I reckon

Tzen

-

21st July 2010, 07:15 PM #36

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- Blacktown

- Age

- 59

- Posts

- 175

Sorry to dig up this old thread but for me its been one of the most in formative (other than a couple of others posted here and some youtube vids) ive been able to find and ive had to keep digging it up.

I havent as yet put my hand to slotting a full board, though Im fairly confident in doing so. Made a few practice runs on some scrap Spotted Gum and it appeared to come out straight and clean. But weighing up the option to buy another saw and make up or buy a mitre jig, i may as well go for the circular blade. I went down the shed and pulled out an old Skillsaw that i had hardly used and has a 13mm sharft (hope thats the right size?) with a half a mill play in the arbor. Powerd it up for 10 seconds and the bearing seized up. Pulled it down to confirm that it was the bearing and spent $4 at Advanced for a new one. I cleaned it up re-greased everything and replaced the bearing. Gave it a good run for about 10 minutes and it purs a gem. The cog and arbor section had a washer spacer of .5mm so i just replaced it with a 1mm washer and now the play is nil. Also found a spare set of contacts in the box, bonus! So im going to make up a table with duel tracks im thinking, while I order a blade from Stew Macs.

I also need to get a fret slot rule, does anyone know if theres one available that has a Fender and a Gibson scale on it? cant seem to find one.

Sorry to rant on im just stoked on it. I post up some pics of the table progress.

Has anyone else gone down this road since?

Greg

-

21st July 2010, 09:47 PM #37

Phil's set up is great, especially for multiscale applications.

I knocked this one up really cheaply. Saw was from bunnings for $112 and still available.

It also takes a Stew-mac saw blade.

https://www.woodworkforums.com/f98/ch...set-up-117129/

.

-

21st July 2010, 10:05 PM #38

GOLD MEMBER

GOLD MEMBER

- Join Date

- Dec 2008

- Location

- Bradbury

- Posts

- 1,429

Greg, Follows stus thread and make one like that!

Ive been meaning to do it for a while now. Its prob the best way ive seen so far.

I was going to try the scms way like the one above, but i would have to get the blade rebored. I think the accuracy would be beta on stus one anyway

-

21st July 2010, 11:04 PM #39

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- Blacktown

- Age

- 59

- Posts

- 175

I was trying to find Stu's thread, i knew id seen it somewhere. If i did do a multiscale it would probably be a one off.I do have a stack of those runners from a filing cabinets somewhere. I used the steel to make Amplifier chassis and stashed the runners. Id say im going to base it on Stu's. Even though my saw fairly quiet, having it boxed in would kill the noise even more. Thanks Stu. Is that your main fret sawer?

Greg

-

23rd July 2010, 12:19 PM #40

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Caves Beach, NSW

- Posts

- 277

Check out this guy's technique...not short on ego.

Freehand with a blunt saw?

[ame="http://www.youtube.com/watch?v=zi-vSydTKTM"]YouTube- The best guitar in the world - Neck - Solid slab of brazilian Rosewood[/ame]

-

23rd July 2010, 10:37 PM #41

-

24th July 2010, 06:28 AM #42

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Caves Beach, NSW

- Posts

- 277

Added link

-

24th July 2010, 11:47 AM #43

GOLD MEMBER

GOLD MEMBER

- Join Date

- Dec 2008

- Location

- Bradbury

- Posts

- 1,429

-

24th July 2010, 02:44 PM #44

At the risk of hi jacking, may I welcome mark to the forum and also add that we really love pictures, yeh lots of pictures, pictures like maybe,,,, if you've got a really cool tool that you made that we could all scab ideas from, you know, like a fret slotting saw that only cost ya $20.00 US, or anything else you'd like to share.

Did I mention we love pics , welcome Mark,

, welcome Mark,

regards to all

Wal<style type="text/css">p { margin-bottom: 0.25cm; line- 120%; }</style> Only two things are infinite, the universe and human stupidity, and I'm not sure about the former. Abert_Einstein.

-

6th August 2010, 08:34 PM #45

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- Blacktown

- Age

- 59

- Posts

- 175

Halfway through making the box, ill finish it off sometime on the weekend. Saw has been ordered so im expecting it the end of next week.

Just bought $70 worth of mixed woods, so for the 150 bucks i spent on the blade and timber, theres enough there to make easily 30 fretboards!

Made up a couple of slot jigs. Fender, Gibson/Ric, PRS and 25.15 scale for myself. The Fender 24th fret is a poofteenth out but i can live with it. Took ages!

Similar Threads

-

What fret size??

By old_picker in forum MUSICAL INSTRUMENTSReplies: 13Last Post: 28th June 2007, 12:30 PM -

fret sawblade

By chanasaurus in forum MUSICAL INSTRUMENTSReplies: 5Last Post: 6th December 2006, 04:25 PM -

fret cleaning

By Chopstick in forum MUSICAL INSTRUMENTSReplies: 3Last Post: 30th October 2006, 01:32 PM -

Fret slotting jig - anyone want to slot some boards?

By JupiterCreek in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 24Last Post: 20th August 2006, 04:31 PM -

What a Diamond! ( Fret Saw )

By Sculptured Box in forum SCROLLERS FORUMReplies: 3Last Post: 20th February 2006, 09:32 PM

Cheers, Stu

Cheers, Stu

Reply With Quote

Reply With Quote