Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 20

Thread: Barker bandsaw

-

26th July 2014, 10:49 AM #1

Member

Member

- Join Date

- Aug 2008

- Location

- Warren NSW

- Posts

- 80

Barker bandsaw

Barker bandsaw

Hi,

I have aquired a 36" Barker band saw. From reading posts in this forum I think it may be a 1930's model that has had a couple of upgrades. The first being wheel gaurds and the latest rework has included a well built dust extraction port and saftey switches on doors and inspection covers. These switches have a bypas time switch which allows some running time with the doors open. Also a light has been fitted along with see through protection around the work area.

All this OHS gear has taken a bit of chacter away from the old girl but I think she will still cut wood.

Now my question: Do the owners of such saws firmly secure them to their work shop floor? What about building a wider footprint or maybe a wider footprint on wind up casters?

I'm just concerned, she looks so fragile standing 2.4 mts tall on a 500mm wide base.

Any thoughts gratefully appreiated

Peter

-

26th July 2014 10:49 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

26th July 2014, 06:12 PM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2003

- Location

- Newcastle

- Age

- 69

- Posts

- 1,073

I've had nine bandsaws and never had to bolt one down. You really shouldn't be pushing that hard against them when they are working. Seriously envious about the old Barker though. Old heavy machines are the best.

-

27th July 2014, 01:16 PM #3

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Hi Peter,

Bandsaws like this look unstable, but the centre of mass is generally fairly low, I would see no need under normal use to bolt these down, just make sure you have a stable floor.

I realise the new OHS equipment takes away from the look, but I would still be interested in some photos, and especially any machinery tags (I may be able to narrow down the date for you).

Cheers,

Camo

-

28th July 2014, 09:40 PM #4

Member

Member

- Join Date

- Aug 2008

- Location

- Warren NSW

- Posts

- 80

Thanks guys for the replys. I have started looking a little harder at the bottom/foot and it looks very unlevel. I don't have any photos yet Camo and while I study the feet the saw is still laying on its side where I unloaded it . It has L S Barker on the edge of the casting just below the table. Also a McPherson limited plate that has been sprayed over. From what I can see the writing on the plate is identical to the centre top of page of that 1930's cataloge posted by Peter McBride. I think my saw is like the Y2090 picture except Barker is cast in a different place.

Will post some pics soon.

Peter

-

29th July 2014, 01:35 AM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Peter,

I can't find the 1930's catalogue Peter McBride listed, that you are referring to, but the McPherson's badge is possibly a big clue, McPherson's changed from Pty Ltd to Ltd on 5th December 1944, so if it is McPherson's Ltd then the bandsaw was made after the end of 1944.

Regarding the bottom foot, is it poor casting, or broken? Take care righting the bandsaw, as based on the stories I have read, this is the time when things go wrong.

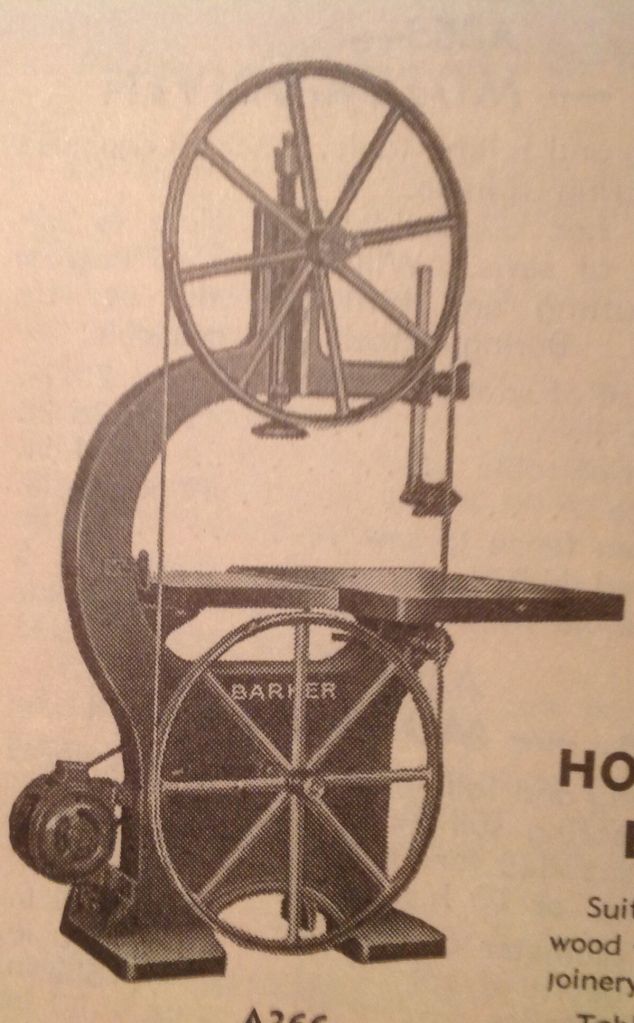

This is what is shown in the 1949 & 51 catalogues:

Cheers,

Camo

-

30th July 2014, 12:02 AM #6

Member

Member

- Join Date

- Aug 2008

- Location

- Warren NSW

- Posts

- 80

Yes Camo that is the saw, except the name there, but I think the same picture is used for a number of years. I have to pull the belt gaurds off and check out the ratios. It appears the wheel speed was uped from 410 rpm to 460 rpm along the way. Also in one of Martys posts he stated that they started casting L S Barker verticily, as mine is, in the 60's. Did the saw look the same in the 60's Camo?

Looking at the feet, no sign of a break or crack. I can't decide wether its a bad casting (I would really doubt that it would not of been dressed) or has been used on a bad surface for a long time. It looks like a bit of corrision plus a bit of abrassion. One corner is at least 5mm shorter then the others. Some enterprising person has at one stage leveled the bottom by filling the feet with concrete and then used megapoxy or somthing similar to glue it to the floor. Then they have moved it and in places the epoxy failed and in others the concrete failed.

So there are a lot of options to correct the instablity. Can't decide which to use.

PW

-

30th July 2014, 09:52 AM #7

Hi.

I have the same bandsaw, pretty much. It's sitting diagonally across a pallet ... because it had to come very slowly down the driveway via pallet trolley

You can see some amateurish fun I was having with it here: https://www.woodworkforums.com/144597...tern-tool-fool

Cheers,

Paul

-

30th July 2014, 08:30 PM #8

Member

Member

- Join Date

- Aug 2008

- Location

- Warren NSW

- Posts

- 80

Finally a few photos .

The one with the straight edge held against the top edge of the two feet shows the out of linement of the base. The gap bertween the straight edge and the right hand foot is similar. I have also held straight edges against the four verticle edges and they are all over the place also. Still thinking of the best solution to level up the base. I could just build a base out of heavy metal and put four jack screws in the corners. Would work but I don't see that as a FIX.

The Mcphersons plate looks like anodised ally. That technology would have to be mid 50's or later I would have thought.

More pics when I stand her up.

Peter

P1011298.jpgP1011293.jpgP1011294.jpgP1011296.jpgP1011300.jpg

-

30th July 2014, 08:35 PM #9

Novice

Novice

- Join Date

- Nov 2012

- Location

- Paynesville, Victoria, Aust

- Posts

- 23

Great pics thanks pmcgee

I was very interested where you mentioned well made guides in the list of tips.

I was wondering what you meant by these. I have a similar Barker saw and have has similar issues that you described.

Would you have any plans or dimensions for these guides?

Any advice in this area would be greatly appreciated

Best wishes

Mark

Sent from my iPad using Tapatalk HD

-

31st July 2014, 02:20 AM #10

I have some old pics from an old phone in that thread ... I can easy take more and better ones.

https://www.woodworkforums.com/144597...ml#post1416353

The small dark squares are what was on it when I got it .. they are metal and had rebated through friction with the blade.

I first used jarrah to replace them, but they wore out pretty quickly.

Then I had some dense sorta marri that I made oversize ... they lasted a while.

So then I went back to metal having come across those zinc-feeling, kinda slippery brackets.

Do you have the same hefty guide-holding mechanism as mine?

-

31st July 2014, 11:34 AM #11

Hi Peter,

It's a Strange solution that some one has done , filling the feet with concrete and gluing it down.

Is it going to be used on a concrete slab ? It looks like a dirt floor in the work shop behind the saw .

I would be chiseling out the concrete and grinding the base reasonably flat.

If it's going to be sitting on dirt, I would set a couple of sleepers in the ground , if on a slab , just sit it on that. Ive never bolted one down either . Bolting it down would be a good idea if other heavy machinery like fork lifts are moving around.

one thing I would be doing is taking off that table before standing it up or moving it around , both of them if it has the two like my 36" does. If you were to lose control of it that will be the first bit that snaps off. it's an all to common sight , broken or missing tables.

Rob

-

31st July 2014, 07:00 PM #12

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Peter,

Unfortunately I don't have a full set of McPherson's catalogues (the relevant catalogues I have are 1949, 51, 55, 61). The 1961 is the first time that the LS Barker appears on the casting horizontally, this is on the Spindle moulder and the Bandsaw, like the one I have:

https://www.woodworkforums.com/172323...Barker+bandsaw

Your bandsaw does not appear in this catalogue, and I believe it also does not appear in the 1960's catalogue.

As I think you picked up, unfortunately we probably can't rely 100% on what is in the catalogue, as they probably used old images, if the only change was the casted name. Also, just because your saw wasn't in the catalogue, doesn't necessarily mean it was no longer available.

I think it would be safe to say that your saw is probably a late 50's/ early 60's saw.

I agree with Rob regarding the base and especially about removing the table.

Cheers,

Camo

-

31st July 2014, 09:57 PM #13

Member

Member

- Join Date

- Aug 2008

- Location

- Warren NSW

- Posts

- 80

Your right RobI would be chiseling out the concrete and grinding the base reasonably flat.

Your right RobI would be chiseling out the concrete and grinding the base reasonably flat. except I will grind it very flat

except I will grind it very flat  .

.

The workshop/storage shed you see does in deed have a concrete floor when you get back past the skillion but the saw is heading for a brand new slab and workshop in town with 3 PH.

I have enough gear to make sure it will stand up without accident but the guys that loaded it were something else.

They gave the impression over the phone that they were all over moving and loading this type of saw and all I needed to bring was my Hilux (8 ft tray ) and couple of pallets and straps.

So I drove 900 Km's to have the d*#$*k heads put it on my truck with their two skip pallets you can see taking the weight of the feet and the table taking the rest of the weight. Had no resourses to do anything about supporting the top. When Questioned they figured putting a few pallets under the top wheel guard and allowing the weight to deform the guard until the top wheel came onto the guard and took the remainder of the weight would satisfy my concerns for the table. I soon stoppped that. I was already pretty furious as I realised that I had been dudded .The top wheel had a major repair that I hadn't been told about and they were trying their best to bust it again

.The top wheel had a major repair that I hadn't been told about and they were trying their best to bust it again  .

.

So I'm 900 k's from home 6 pm in the middle of a industrial area in a city. I strapped it down and drove very slowly out in to the country, my inviroment, and the next day I found a very helpfull young guy who had enough gear to lift the saw top up and build the support that you can see screwed to the blue pallet.

The drive home was then incdent free .

.

I just whish I had spoken to you guys before that adventure.

Camo does the style/material of the McPherson badge indicate an era?

Peter

-

31st July 2014, 10:16 PM #14

Member

Member

- Join Date

- Aug 2008

- Location

- Warren NSW

- Posts

- 80

Oh pmcgee,

I just looke at the photos of your guides. From memory my saw has the same with out the grease nipple (if that is a nipple in the centre). My side guides are new brass but I'm not up to trying them out yet.

Peter

-

31st July 2014, 11:23 PM #15

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Similar Threads

-

My new old Barker Bandsaw

By camoz in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 27Last Post: 8th February 2022, 09:19 PM -

L. S. Barker Bandsaw ... heavy castings

By lightwood in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 52Last Post: 3rd August 2020, 12:16 AM -

Barker Bandsaw on gumtree

By 2blast67 in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 1Last Post: 30th June 2013, 05:22 PM -

Barker 36" bandsaw

By Stringy in forum BANDSAWSReplies: 8Last Post: 6th April 2010, 11:31 PM -

Ronnie Barker R.I.P.

By normell in forum WOODIES JOKESReplies: 10Last Post: 20th October 2005, 10:50 PM

Likes:

Likes:

Reply With Quote

Reply With Quote