Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 6 of 6

Thread: Is this the future ...?

-

21st February 2011, 11:21 PM #1

Is this the future ...?

Is this the future ...?

For the past two years John Payne and I have been discussing steels used in knife-making, and their has potential application to woodworking tools. He has already produced a number of chisels in CPM 3V steel, and these have demonstrated superior edge-holding to A2.

John sent me a three chisel blades and 1 plane blade to test. I have not reached the testing stage yet, but I thought I would show the steel and pass on my observations with regard sharpening them.

This weekend has been all about painting. Oh how I hate painting walls! Every now-and-then, however, I managed to escape (while the paint dried) to the workshop to make the chisels.

This is what I produced over yesterday and today:

From the Jarrah handled CPM 3V, She-oak handled CPM M4, and Bloodwood handled CPM 10V.

The Bloodwood handle is rather special. Exactly 2 years ago Tony Zaffuto (TonyZ) sent me a piece of Bloodwood infused with Resinol, a piece large enough for one chisel handle. I've been saving it for something special. I think that 10V qualifies. Thanks again Tony!

All of these handles can take a serious beating, but the Bloodwood/Resinol is effectively indestructable.

The chisels are all 3/4" wide. I plan to test them out chopping the endgrain of dovetail pins. So I have also hollow ground the shoulders to make it easier to avoid bruising the edges of the dovetails.

The 3V is ground at 25 degrees (as it will cope with this), while the M4 and 10V are ground at their preferred 30 degrees.

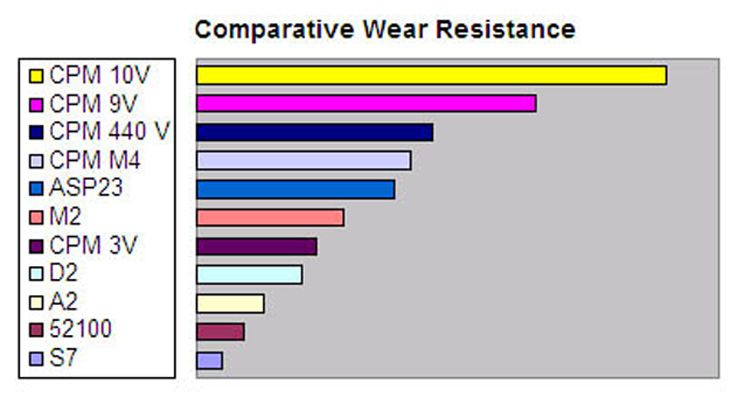

How tough are these steels? Here is a chart comparing them ..

Source: Hamilton Knife and Machine - CPM 10V Steel

M2 steel is the HSS with which we are familiar. This has more than double the wear resistance of A2. Now M4 is about double M2 (with 3V a little behind M4), and 10V is more than double that!

Sharpening ...

I hollow ground all the blades on an 8" grinder with a Norton 46 grit white wheel. Grinding was not too bad, but clearly slower on the 10V. The advantage to using these steels is that you do noit have to be concerned about overheating them.

I have been using a couple of CPM 3V plane blades for a while. Sharpening has been hit-and-miss. Pro Shapton 1000 ceramic waterstones remove the steel without any difficulty (in fact this stone is fast), but I have been less happy with the 5000 and 12000 Pro Shaptons on this steel.

Consequently I decided to just use oil based diamond paste on all the stones. I have a set up that uses steel plates (from an old saw) glued to hardwood. The set comprises 40, 10, 1 and .5 microns.

This combination quickly created a razor edge on the 3V and M4 (the M4 literally laughed at the Shaptons, which made no impression on them). However try as I might, I could not get past fine scratches and a dull grey finish with the diamond paste on the 10V. Out of sheer desparation I turned back to the Pro Shaptons ... and you know what - they rapidly turned the scratches to a shine! Go figure.

I have lots of dovetails to chop/pare in my current project, so the next month should see these blades getting a solid workout.

If you are in Perth and attend the LN workshop in March, look out for me - I am one of the presenters. These chisels will be there and you are most welcome to have a go with them.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

21st February 2011 11:21 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

22nd February 2011, 07:52 AM #2

Very nice Derek, looking forward to the results.

Regards,

Denim.

-

22nd February 2011, 01:56 PM #3

Hi Derek,

Interesting stuff, I've been following the threads on SMC and Woodnet with more than casual interest since I seem to have been doing more metalworking lately, and have started looking at what I need in a heat treatment oven.

The advances with these crucible particle metallurgy steels is amazing, and it will be very interesting to see how they really perform in reality.

I regularly use carbide insert tooling on the lathe and mill, and I note with interest that they claim that CPM-10V can replace carbide for some tooling applications.. wow...

Here is a link to more detail on CPM-10V

Crucible Selector - CPM® 10V

I await the results of your testing with interest.

Regards

Ray

PS I've been looking for the summary of tool steels that Helmut (aka Thumbsucker) did a couple of years back when the D2 M2 plane blade group purchased were done, I'm sure that he would have some experience in this area..

-

22nd February 2011, 05:59 PM #4

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

Many of us have bought CPM 10V turning tools from the US. The extra abrasion resistance is very helpful doing long distance with so many of our timbers.

They grind well on an Alox wheel. I've not tried to refine an edge on one.Cheers, Ern

-

22nd February 2011, 06:45 PM #5

Hi Ray

There has been a good thread on Wood Central: Is this the future ...?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

22nd February 2011, 11:39 PM #6

Hi Derek,

Very interesting test coming up, to see how sharp an edge they can take and what it takes to keep the edge touched up after a good work out. I do like that Bloodwood handle.

Hope to see you at the LN workshop.

Cheers

Pops

Similar Threads

-

Future WIP

By Powerb in forum WOODWORK - GENERALReplies: 6Last Post: 17th September 2010, 11:33 PM -

Help a newbie and even future ones?

By Big Bird in forum FINISHINGReplies: 5Last Post: 6th December 2007, 07:31 AM -

The Future is Here

By Grunt in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 10Last Post: 6th April 2006, 09:29 PM -

The Near Future

By woody62 in forum TRITON / GMCReplies: 46Last Post: 5th August 2005, 07:34 AM

Reply With Quote

Reply With Quote