Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 21

Thread: My shed layout plan

-

28th March 2012, 12:48 AM #1

My shed layout plan

My shed layout plan

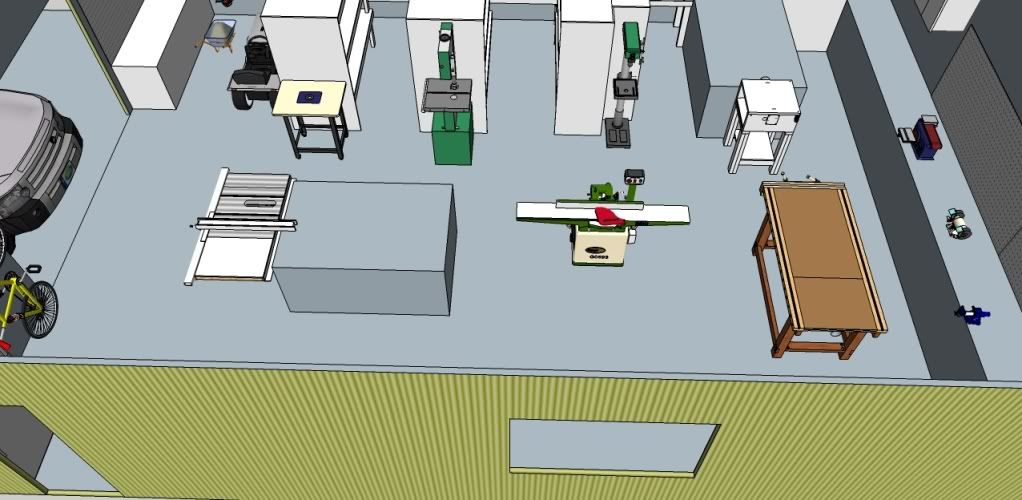

I have ditched my shipping container idea and think I can afford to get a real shed. I've got a 5 acre block but have managed to find myself in a position where the biggest shed I can fit will be 7.5m x 10m x 2.7 with a 7.5m x 7.m carport on the front.

Once I've decided that I'm not going to make any more changes to my plan I'll do the rounds and get prices and specs from the shed companies. So far I'm planning to see Sidach and Ranbuild.

The plan is to have the shed for storage and for finally getting into some woodwork. I won't be restoring cars or housing tractors etc. I'll have garden tools and mowers at this stage but may build a garden shed for those at a later date.

Eventually I'll have a DC and compressor housed just out side the shed a la BobL.

I'm going to paint the floor (shed first concrete second) and go to town with the sparky. No three fase.

I'm expecting it to cost me about $20k for the shed, concrete and power. I'll install it myself with a mate who used to be in the installation game.

These are my initial plans for the layout.

-

28th March 2012 12:48 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

28th March 2012, 07:46 AM #2

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2007

- Location

- Blue Mountains

- Posts

- 817

What a great opportunity!

I noticed that you've got your jointer placed near your bench, and it's also facing across the shed. From my experience, I'd try to place it away from the bench so you have access all around the bench, and I'd also want it to have as much clearance on the infeed and outfeed as possible, so I'd swing it around 90 degrees.

cheers,

ajw

-

28th March 2012, 08:53 AM #3

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2002

- Location

- NSW

- Posts

- 1,610

What about including dust collection piping in your layout?

Are you going to bury it in the floor, or run it around the ceiling, with drops to each machine?

Cheers,

Andrew

-

28th March 2012, 09:22 AM #4

I don't like the jointer being around the workbench, you need to be able to work on workbench from all 4 sides.

I would make the assembly table as the outfeed table for the tablesaw, turn the tablesaw around and you will get heaps of space for ripping long boards. That will give you more room for the jointer.

(Oh, that is basically what ajw said. Sorry!! )

Visit my website at www.myFineWoodWork.com

)

Visit my website at www.myFineWoodWork.com

-

28th March 2012, 09:38 AM #5

Where are you going to store the longer pieces of wood or sheet goods?

-

28th March 2012, 10:00 AM #6

Whats the reason for so many shelves, they take up a lot of space.

As the others have indicated spin the table saw and jointer to give you longer infeed and outfeed.Jim Carroll

One Good Turn Deserves Another. CWS, Vicmarc, Robert Sorby, Woodcut, Tormek, Woodfast

Are you a registered member? Why not? click here to register. It's free and only takes 37 seconds!

-

28th March 2012, 10:24 AM #7

Looking at the plan it appears you will have an overhang for the carport. Why not put double doors on the end of the shed so when they open they can be locked to the carport posts, giving you a much larger shed that is open at one end? Great for working large bits, welding, spraying etc.

-

28th March 2012, 11:25 AM #8

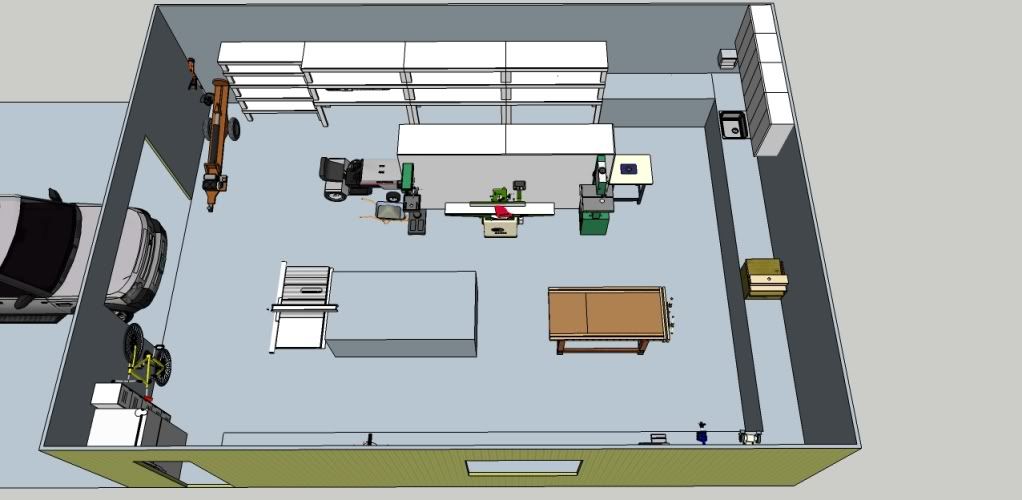

I've taken the advise of the jointer and saw position on board and moved them around. As far as the jointer, thicknesser and table saw go I don't have them at the moment but will eventually get them. I have about 10 minutes experience using each of the above and that was about 3 years ago. The thicknesser will be on wheels or else may sit on the back bench where the grider and belt sander are.

On the dust collection, I will have that coming from above.

At this stage I'll store sheets and long pieces of timber on top of the shelving but I am open to suggestions.

I've put in a lot of shelving because I'm scared of not having enough room. Despite best efforts I'm not as tidy as I would like to be so I want to have a space for everything.

Groggy, the double doors sound interesting. I'd say no at this stage but it is food for thought.

-

28th March 2012, 12:04 PM #9

That is much better. You might still have trouble with long pieces (2m+) on the jointer. I would put it on a mobile base, so you can move it around or turn slightly in an angle.

Visit my website at www.myFineWoodWork.com

-

28th March 2012, 06:39 PM #10

Member

Member

- Join Date

- Dec 2009

- Location

- WA

- Posts

- 78

If you are going to purchase a c section kit, see if it can include an apex brace. The apex brace is usually a z section or c section which sits up under the apex brackets and provides bracing.

Sheds are not designed for dead loads, but if you kept the load to a minimum (say less than 100kgs), you would be able to store the odd long length of longer timber up in the roof space as it were.

For caution I would ensure the frame is either a size or guage heavier than standard engineering for a bit more “insurance”. Ensure the brace is bolted rather than tekked.

-

28th March 2012, 06:43 PM #11

Member

Member

- Join Date

- Dec 2009

- Location

- WA

- Posts

- 78

Out of curiosity- what program is that you are doing the drawing with? Is it easy to use?

-

29th March 2012, 12:04 PM #12

Good old Google Sketchup. I love it. I think it is an easy a program as you can get and the price is right (free). Google it and it will come up.

One thing I like about it is that is very widely used and people up load their drawings. That is how I got all the pictures for my machinery.

I drew the basic shed and benches then searched jointers etc and downloaded the ones that I liked and were well drawn.

-

30th March 2012, 02:21 AM #13

I changed a few things around. Got rid of a bench and some shelving, added a log splitter.

Last edited by Arch Stanton; 30th March 2012 at 02:23 AM. Reason: typo

-

30th March 2012, 09:47 AM #14

-

30th March 2012, 09:41 PM #15

Arch

Nice plans. A few thoughts.

Why are you using open shelves? In a woodshop, unless you manage to capture all the dust, things on the shelves would get dusty quickly. I would use cupboards instead if you can.

You have a zillion acres of bench space around the walls of this shed. You can never have too much bench space but I think you would be close. Setting aside the cost of making/buying cupboards, I'd be inclined to convert some benches to shelves and free up the space used by the island of shelves. You also need to think about clamp storage (can never have too many clamps). But perhaps you have a lot of stuff to store!

You don't have a chop saw/compound mitre saw for docking material to length. Or Perhaps I've missed it somewhere. I know you can do most things with a table saw and hand held circular saw, but nothing beats the simplicity of a chop saw for cutting things to length.

I like the sink. You should plan to put your sharpening station nearby too, so maybe leave some more space from the corner (or remove the corner cupboards). And kudos for the beer fridge.

I'd be inclined to separate out the gardening equipment. Petrol and woodwork tools don't often mix well. And you don't want your shed smelling like grass and fuel. There are always cans of fuel, oil, rags, etc.

Anyway, just a few suggestions.

TravSome days we are the flies; some days we are the windscreen

Similar Threads

-

shed layout

By Trav in forum THE SHEDReplies: 1Last Post: 6th December 2011, 12:51 PM -

Turning shed layout

By hereward in forum WOODTURNING - GENERALReplies: 22Last Post: 3rd July 2010, 07:11 PM -

Shed layout advice please.

By Rattrap in forum WOODWORK - GENERALReplies: 18Last Post: 30th October 2008, 05:46 PM -

Shed layout. Good or Bad

By DJ’s Timber in forum WOODWORK - GENERALReplies: 24Last Post: 9th January 2007, 02:32 PM -

Powerpoint Layout for 10 by 7 Shed

By NewLou in forum WOODWORK - GENERALReplies: 16Last Post: 31st December 2005, 02:20 PM

Reply With Quote

Reply With Quote