Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 59

Thread: New table saw

-

4th March 2014, 03:28 PM #16

Senior Member

Senior Member

- Join Date

- Aug 2008

- Location

- Canberra

- Posts

- 420

Silent means a lot... I am scared of the sound that my dewalt makes during the day!

As a side note - will helical head handle burl???

-

4th March 2014 03:28 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

4th March 2014, 03:46 PM #17

You got some for me to try it out on? Lol bring it around and lets test

-

4th March 2014, 03:52 PM #18

Senior Member

Senior Member

- Join Date

- Aug 2008

- Location

- Canberra

- Posts

- 420

I would be scared, at least putting it through in a thicknesser mode, after reading how people destroyed thicknessers trying to plane end-grain boards!

-

4th March 2014, 05:46 PM #19

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

Silent is stretching it, but it is significantly quieter. I tested the thicknesser at work before and after we did the switch to Shelix and there was a 9 dB reduction in noise.

It handles endgrain with no issue, but it does wear the cutters MUCH faster than normal. Never tried burl but, as long as the cutters are sharp, I can't imagine there being a problem.

-

4th March 2014, 08:21 PM #20

Id like to test the dB difference between a hammer helical head to a shelix head. The shelix head has a lot more cutters thsn the hammer cutters

-

4th March 2014, 09:11 PM #21

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

The hammer head will probably be a bit quieter, just going on looks. I'd also be interested to compare the finish from both, the hammer head has 2 rows of cutters, our shelix has 10 (and they're due to be replaced at the next sharpen, so that'll be a fun couple of hours for me

). The shelix cutters are also ground with a slight radius instead of square, what are the hammer ones like?

). The shelix cutters are also ground with a slight radius instead of square, what are the hammer ones like?

-

5th March 2014, 10:16 PM #22

I think it would be quieter as from memory it only has 2 runs of 23 cutters the rest is spindle. Fun times ahead replacing all those. Mine are still on their first run on the first side out of 4. Havent even rotated them yet.im no priduction workshop though

Oh okay I didnt know that. No mine are dead square but placed on an angle to shear through tge wood fibers instead of dead straight on.

-

24th April 2014, 03:31 PM #23

Senior Member

Senior Member

- Join Date

- Dec 2004

- Location

- Perth

- Posts

- 324

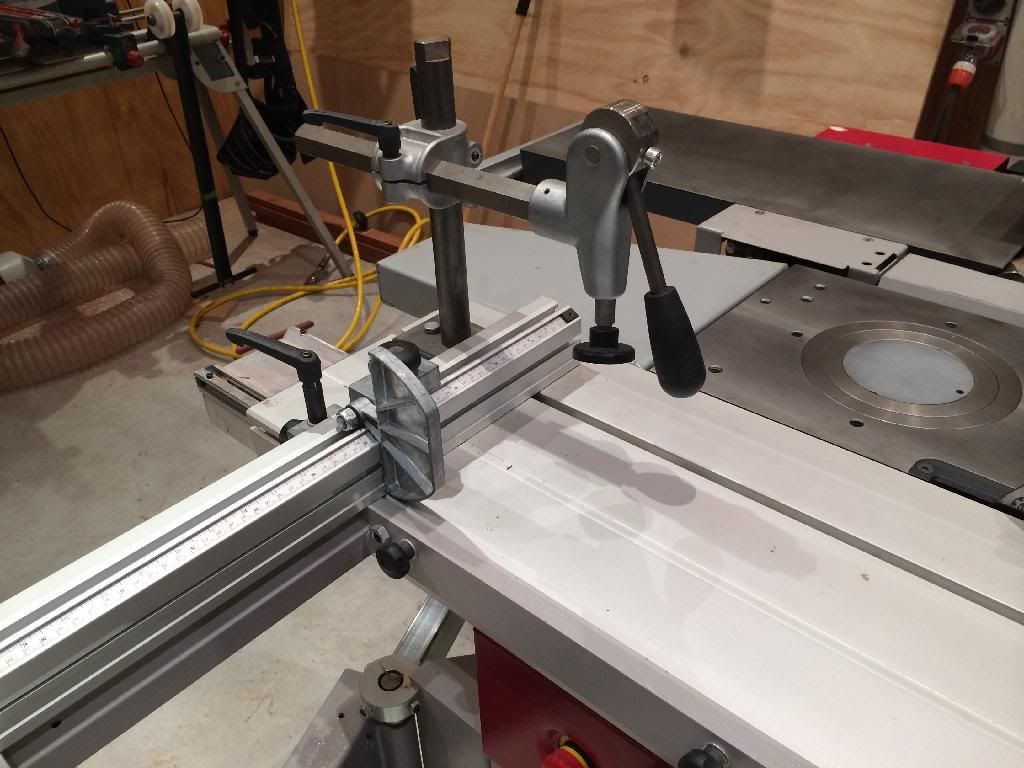

Hey delbs, how are you getting on with the beast? I got mine delivered about the same time you got yours. If you've got a bit of cash to throw at it can I recommend the Felder eccentric clamp. I think mine was about $270 with the base plate but it's a great investment. I've got it set up behind my crosscut fence and it's great (particularly with sheet goods).

I also bought the dado set which is amazingly good but excruciatingly expensive.

-

24th April 2014, 10:14 PM #24

Hey Dale

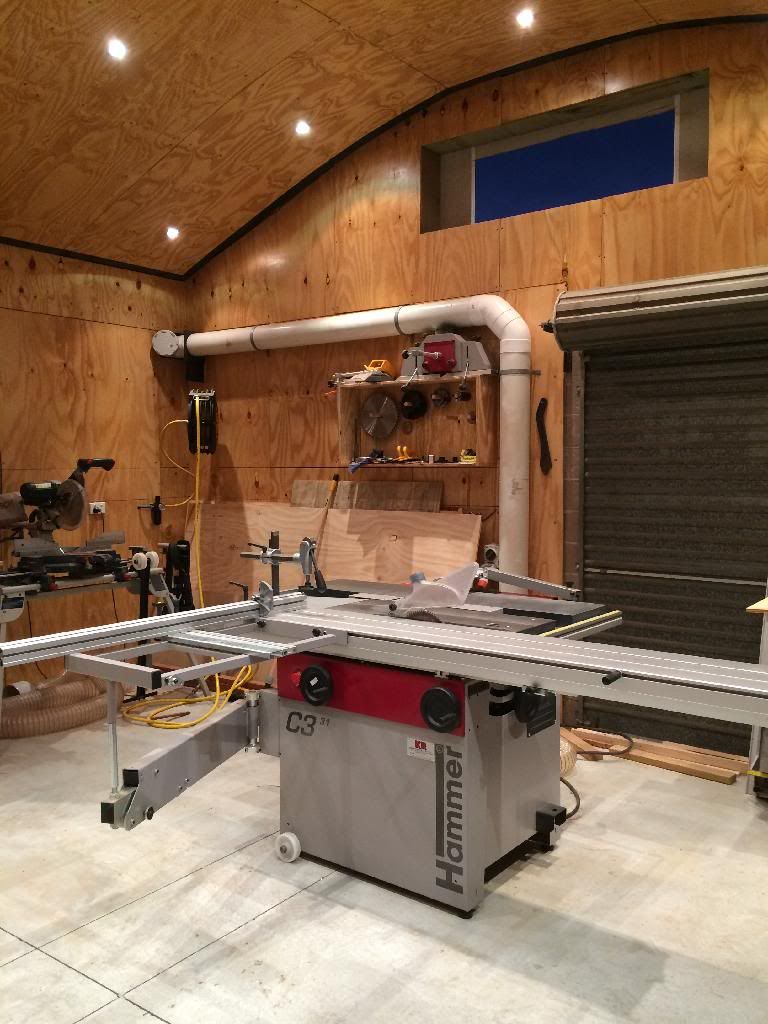

Since I took delivery of it it sat there until I sorted out the power unused for roughly 2 or 3 months. I obssessed over the manual and accessories. Then once it come online to say I was a kid in a candy store would be an understatement haha.

Its my most used machine and now ive gotten in an order with squaring and sizing up stock I find it soooo easy and simple to switch between. I have a decent workspace of a garage but I cant grt over how much more space I have since selling off and combining the fuction of my thicknesser, jointer, tablesaw into this unit. The spiralhead thickneser and jointer is amazing. Finish is so nice and I can use it at night without complaint from anyone including my sleeping kids less thsn 10m away. Ive been reading about the hammer dado set or forrest blades but havent done anything about it. I have some hold downs in the mitre track which work a treat for now but that eccentric clamp looks awesome and behind the crosscut fence would be a great addition.

Do you have a c3 31 or something else? Do you have the sliding table or outrigger attachment? Ps sorry for the long response

-

25th April 2014, 02:44 AM #25

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

I bought some Forrest blades for mine and they are very nice I must say. Make sure you keep the debris away from the base of the cross cut fence as it will affect the cut when cutting longer sheets. I am going to do something like this when I get a chance...

http://www.youtube.com/watch?v=DqzVglze9Nk

Yes, it is in German but the method is fantastic. How was the crosscut fence attached to the leading edge of the slider? Were the zero stops down there as well? I have looked at the idea but I would have to buy another set of zero stops. What I found helpful was to buy another sliding stop for the cross fence so I can have two settings and swap between them. The sliding rip fence on mine is the micro adjust fence and until recently it was very reluctant to move unless it was held in a very particular way. I have applied some silicon lube to it a few times and that seems to have fixed it. I am going to fit a Wixey digital fence gauge to it when I get enough motivation, I think one of the users on FOG has done the same thing. When they make FOG a proper forum I might go back to it.CHRIS

-

25th April 2014, 10:51 AM #26

What saw do you have these days chris? Last I saw you had the carbatech one?

-

25th April 2014, 12:17 PM #27

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

I still have that saw as no one seems to want to buy it, three phase is the issue there. Anyone want a three phase 12" saw with a few nice accessories, cheap cheap? I bought a new K3 winner which is a stand alone version of what you have and it is very nice after I sorted out why it wouldn't cut square using the cross cut fence. I have used it extensively doing the workshop renovation making about forty drawers and cabinets for the drawers. It was my retirement present to me along with a new (used) PM thicknesser and a Minimax BS to replace the Jet.

CHRIS

-

25th April 2014, 01:53 PM #28

Very good. They will last you a lifetime. Did you make a zero clearance cross cut fence given tge 9cm offset from the blade? Why wasnt it square? Yes sorry to answer your last post I only have one set of mitre angles and zero stops at the tail end of my slider I would have to buy another set. I dont see a need for me to change it im happy with it at the back

It does take me a few taps to get the rip fence accurately set to the blade but its fine once its there. Its no incra for repeat cuts though. A digital readout would be nice but I dont see a huge need for it at the moment still find it nore accurate than my old saw. Yeah I get the fog wmails. Very helpful bunch of guys on there

-

25th April 2014, 09:33 PM #29

Senior Member

Senior Member

- Join Date

- Dec 2004

- Location

- Perth

- Posts

- 324

Mine's a C3 31 but I got it with the comfort package with the outrigger and 2m slider.

To say I'm happy with it would be the understatement of the century. Admittedly I've come from a triton, but every time I switch it on and hear those big 3 phase motors whir into life I get a pretty big grin. I also got the scoring unit, the digi handwheel for the thicknesser and the spiral head. Haven't done a lot of solid timber yet. It's all been sheets of MDF and ply to build my shed and cabinets but it's amazing how quick it's come together. I started with a cut list and 9 sheets of MDF and 1 hour and a half later I had 9 cabinets cut out. 1 hour later with the dado set I had the most perfect rebates cut into the sides and backs so they all went together like a mechano set. I was stunned!! That would have taken me days with my triton.

In my opinion, the clamp is money well spent. It's a huge heavy duty affair that clamps down super solid, super easily. Especially for sheets, lets you concentrate on pushing stuff through rather than holding it straight.

You need the saw set up to take the dado set (it's an option at time of purchase). I really wrestled with the purchase, it's crazy expensive (like over $1000) but I'm really happy to have it now. It cuts the most perfect rebates, perfectly flat with almost polished faces. Uses similar blades to the spiral head on the thicknesser. I'm just about to do a really big renovation and I'm building all the cabinets and wardrobes. Not sure if I would have spent the money on the scoring unit and dado set otherwise.

Can'r believe how quiet the thicknesser is. I live inner city Perth and work shift a bit. It made me laugh when I was thicknessing 250mm Jarrah the other night at 11pm and the only noise I was worried about was the dust collector! Crazy...

It's a pretty nice bit of gear (but it'd wanna be for the money).

-

25th April 2014, 11:12 PM #30

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

I have no idea why it was not square and it is not intuitive to get it square. I don't understand the zero clearance bit as the cross fence stop can't be used safely under 90mm as there is only about 40mm between the end of the fence and the blade and my fingers aren't going in there! If you want to cross cut really short stuff set the rip fence as the stop and pull it back to the leading edge of the blade to avoid entrapment of the off cut. I may be missing the whole point which wouldn't surprise me at all. The whole FOG thing leaves me cold, email lists died about 10 years ago and that is a good place for them.

I let the comfort package slide when I bought mine to see how it went as it is no more expensive to buy it later on and I have yet to regret not buying it initially. I rough cut 2400 sheets in half and then put them on the saw, true up the cut edge and then start working. My issue is that with two stuffed shoulders I could not get a full sheet on the saw anyway so I most probably will not go there. If I was doing repetitive sheet work with someone else helping it would be the first thing I would buy as it is not a stupid price IMO.

PM me you phone number, I would like to have a chat.CHRIS

Similar Threads

-

Sliding table and out-feed table for TSC-10HB table saw

By mikm in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 31Last Post: 24th July 2009, 12:58 AM -

Sturdee’s collapsible sheet cutting table & extra workbench/assembly table.

By Sturdee in forum THE WORK BENCHReplies: 7Last Post: 13th November 2008, 07:53 PM -

What's The Difference Between A Pool Table & Snooker Table & Billiard Table

By echnidna in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 47Last Post: 26th January 2007, 05:09 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote