Results 796 to 810 of 1535

Thread: 2/3 scale Indian Straight Four.

-

21st September 2014, 07:45 AM #796

I have been watching this thread and still find it amazing.

-

21st September 2014 07:45 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

21st September 2014, 03:55 PM #797

-

22nd September 2014, 08:11 AM #798

Thanks for the kind words I'm glad your still enjoying the build.

Although at times it's driving me a little nuts.

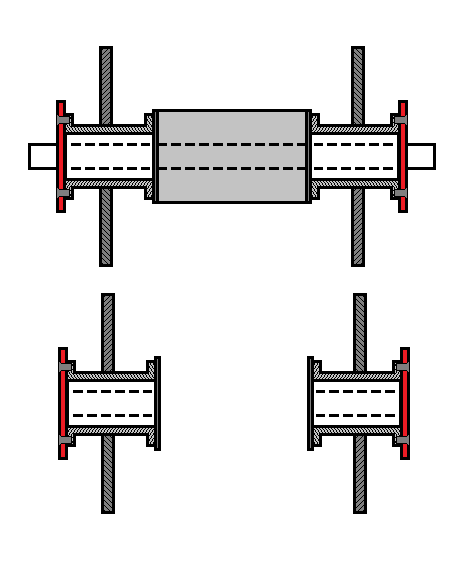

At the moment I'm trying to workout the best way to arrange the rear wheel.

I need the wheel itself to turn freely while everything else (the drive sprocket and the drum brake) stay still.

The speedo drive is mounted on the spokes so it obviously has to turn with the wheel.

While I was at Joe's he made a spacer for the Drive sprocket out of an old aluminium compressor part.

It gave me the idea of isolating the drive sprocket and the drum brake by having them on their own posts.

Which would be screwed to the frame itself.

I'm not to sure that my drawing below will make to much sense, but hopefully it gives some idea of what I'm thinking.

The red section is the frame and the light grey the hub.

With the posts mounted either side the idea is that when the through axle is removed the wheel comes away,

leaving the brake and the sprocket in place on the frame.

At the moment I'm pretty confident that it should maybe kinda work!

But I'd be more than pleased to hear of any ideas or modifications that improve on it.

Cheers

Trev.

-

23rd September 2014, 02:47 PM #799

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

I haven't dropped in here for a while but I am still stunned by this build!!

This looks so real it is uncanny.

Brilliantly done sire!!!

-

24th September 2014, 02:53 AM #800

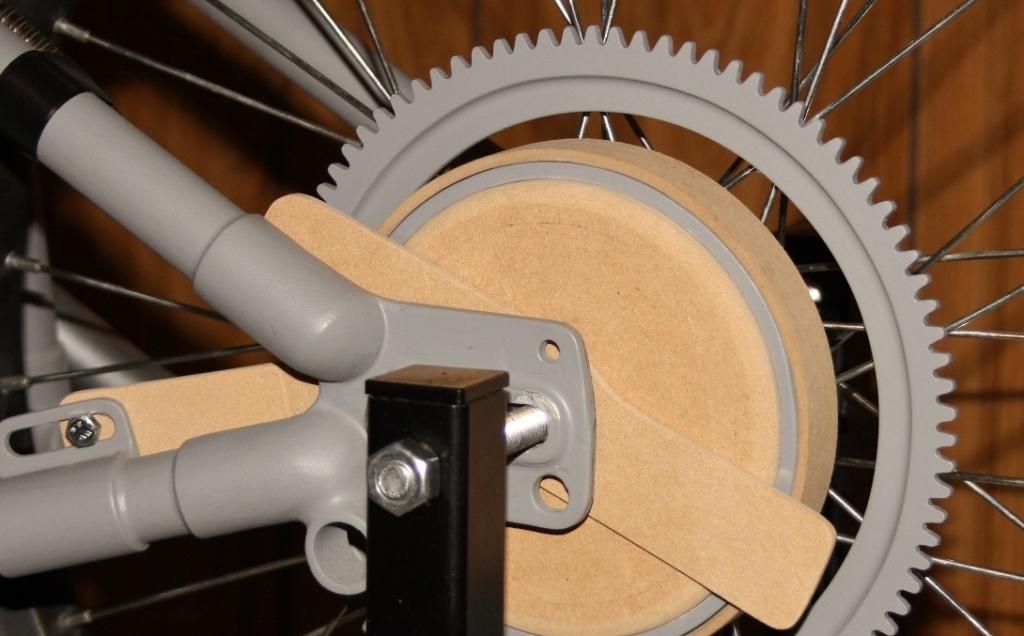

I got a start on the rear brakes.

Their the early style of drum brakes having the bands on the outside.

When you'd put your foot on the brake the bands would contract down onto the drum.

The picture below is what the brake should look like when finished.

So far I've made the drum, the mounting plate and what will be one of the brake pads.

In the picture below the brake pad is sitting over the drum which is in primer.

I need to make some metal straps to go over the pads.

I'm hoping the sides of a coffee tin cut down will be thick enough for the job.

The brake pad is 3mm MDF that I steamed into shape.

I'll make another one today then cut them down to size.

Cheers

Trev.

-

24th September 2014, 09:31 AM #801

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2013

- Location

- Torquay

- Posts

- 4,422

Hey Trev,

The rear sprocket looks great in position. Looks like you are really getting your teeth into it !!!

Keith

-

24th September 2014, 10:51 AM #802

Hey mate

For a guy who wasn't to sure how puns are structured you're a fast learner!

You almost seem to be "chomping at the bit" to use them

Glad you like the speedo drive sprocket after making it I've got a hole new respect for your work on the Peny-Darren.

Cheers mate

Trev.

-

24th September 2014, 03:32 PM #803

Been a while since I stopped in and I am even more impressed than I thought I would be. Great work on the drive gear and brake. I have one question though. Where did the drive gear from the tranny go? Wasn't that on the other side? If so, isn't the wheel on backwards?

He who blesses his neighbor in a loud voice, rising early in the morning, it shall be counted as cursing!

Videos I have made. Abandon All Hope Ye Who Enter Here!

https://www.youtube.com/user/johnnie52/videos

-

24th September 2014, 03:56 PM #804

Hi Johnnie

Good to hear from you mate hope your well.

I dropped the drive the other side while I'm working on the brake.

At the moment I wouldn't be to surprised if the wheel was on backwards.

I'm having a great time making all this stuff.

But it's a headache scale is out the window due to the bicycle wheel being so different to a motorcycle.

I'm just trying to make things look as if they may work

Still it's all good fun!

Cheers mate

Trev.

-

24th September 2014, 08:56 PM #805

Absolutely amazing work Trev. Glad I stopped back to have another squiz.

Cheers, Ian"The common law of business balance prohibits paying a little and getting a lot.. it can't be done.

If you deal with the lowest bidder it is well to add something for the risk you run.

And if you do that, you will have enough to pay for something better"

-

26th September 2014, 01:15 AM #806

Thanks for that Ian glad you like it.

Yesterday I got quite a lot done with the rear brake pads.

I had to give away using MDF as it wasn't standing up to it,

So I made some out of PVC their a lot stronger and hold their shape really well.

The rivets are nail heads painted up they should look the part.

Today I'll hopefully get the lever made and I can connect it all together.

After that I need to mount it all on a post that keeps it isolated from the movement of the wheel.

Cheers

Trev.

-

26th September 2014, 09:53 AM #807

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2013

- Location

- Torquay

- Posts

- 4,422

Trev

That is fantastic work. Your eye for detail is unbelievable. I thought the only break you took was a coffee break (brake) and now you come up with this.

Can't wait to see the next component.

Keith

-

26th September 2014, 09:19 PM #808

-

27th September 2014, 02:57 AM #809

I don't know Crowie I reckon if you've got a new toy this is the right forum to show it off.

I didn't get the brake lever finished yesterday but it's basic shape is there.

It took awhile to get the position of the holes right.

But I'm pretty happy with it.

When you move the lever the brake pads close.

Not that it matters it's not as if it needs to work.

I should have the brake done today.

It shouldn't take to long depending on how many times I stop for coffee.

Then I'll get to work on positioning the drive sprocket on the other side of the wheel.

Cheers

Trev.

-

27th September 2014, 03:02 AM #810

Similar Threads

-

How straight does a straight edge need to be?

By Sir Stinkalot in forum WOODWORK - GENERALReplies: 20Last Post: 8th November 2013, 10:41 AM -

Aluminium straight edge - not so straight

By Dengue in forum WOODWORK - GENERALReplies: 28Last Post: 7th November 2010, 09:54 AM -

How straight is your straight edge?

By echnidna in forum HAND TOOLS - UNPOWEREDReplies: 17Last Post: 5th November 2005, 10:12 AM -

3m straight edge - or how straight can one get angle iron

By burn in forum WOODWORK - GENERALReplies: 10Last Post: 16th February 2004, 07:06 AM

Thanks:

Thanks:  Likes:

Likes:  Needs Pictures:

Needs Pictures:  Picture(s) thanks:

Picture(s) thanks:

.........

.........