Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 43 of 43

-

21st November 2014, 08:03 PM #31

Intermediate Member

Intermediate Member

- Join Date

- Sep 2012

- Location

- AUstralia

- Posts

- 44

Yeah very similar to the carba tec one, I bet they are made in the same factory.... I only bought the Hafco from Hare&Forbes cos their delivery is so much faster for me... and far better customer service I find, Would be great to replace the cutters with Carbide, I bought a pack of 10 regular spares with it and I guess they will last me a fair while considering I only really do hobby stuff. Very simple to change or rotate, takes a few minutes..... I think for around $700 these are great for the hobbyist with a small shop.... Still a fair investment though. I will keep my eye on the thread. Many thanks....

-

21st November 2014 08:03 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

21st November 2014, 08:23 PM #32

Intermediate Member

Intermediate Member

- Join Date

- Sep 2012

- Location

- AUstralia

- Posts

- 44

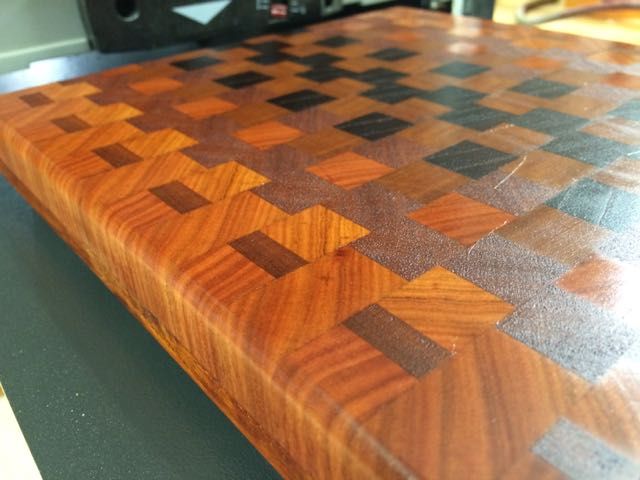

Just for reference, the Hafco Woodmaster T-13S let me do this to endgrain:

With very little sanding...

-

2nd December 2014, 05:36 PM #33

Novice

Novice

- Join Date

- Dec 2014

- Location

- Australia

- Posts

- 13

T-13s

T-13s

Wish my HAFCO T-13s was that good. Mine was terrible. Head was way out of whack, left streaks all over the timber, rises and dips. Had to do so much sanding that it wasnt even worth using.

Would highly recommend staying away from the T-13s as its over priced for the results you get.

Returned mine for repair but still terrible. Will be asking for a refund now.

-

2nd December 2014, 08:13 PM #34

Intermediate Member

Intermediate Member

- Join Date

- Sep 2012

- Location

- AUstralia

- Posts

- 44

Sorry to hear that, If they are reluctant to do a refund ask for a replacement. I guess with this brand it's a bit of a lucky dip.... Sounds like something inside is loose if it's going up and down.... Could be dangerous....

I stripped mine down when I first got it and checked every thing before I used it. Some stuff was a bit loose but I couldn't see any issues....I was a little suspicious with this when it arrived as I had issues before with a hare&forbes Drill press and a very badly assembled router table where from the factory they both needed a far bit of "tightening up". These things do a significant amount of RPM for their size so best to make sure....

I Had some initial snipe issues as it is quite impossible to set the infeed and outfeed tables correctly, I fixed this but laying a scrap piece of 33cm wide melamine over the whole infeed and outfeed. Now it does pretty good cuts and even end grain without issues...

Good luck....

-

2nd December 2014, 09:02 PM #35

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2014

- Location

- Australia

- Posts

- 660

I have not tried my CTX-330X machine yet. To busy fighting neighbors for a shed. I bought mine for a specific reason.

But for endgrain my 15" does pretty good job with no snipe, tearout or kickback. Any chinese machine off the shelf seems to be rubbish unless you spend the time to set it up and tune it, which is a pain in the proverbial. I put a nail through my 15" machine recently after I fitted new blades and now its all buggered and thats all it takes.

To date, I have done no fine furniture, my machine has been used almost 100% for renovations with the exception being end grain cutting board from scrap and a few odd joinery jobs.

-

3rd December 2014, 11:06 AM #36

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jul 2009

- Location

- inverloch

- Posts

- 472

I also have the Carbatec 330x. Apart from some initial mucking about to rectify some sniping it has been a good purchase.

In the light of centron's post I ran some end grain oregon through it and experienced some tear out - a bit more than could be sanded out with an orbital sander. Would need a thickness sander, however for all other wood I have run through it up to date the finish has been excellent. The spiral head is an improvement on straight knives but obviously not as good as a helical head. Still very happy with the machine apart from the cost of the cutters.

-

3rd December 2014, 11:11 AM #37

Intermediate Member

Intermediate Member

- Join Date

- Sep 2012

- Location

- AUstralia

- Posts

- 44

-

3rd December 2014, 09:32 PM #38

[QUOTE=Evanism;

This thread has reinvigorated my desire to upgrade to carbide as I flipped the HSS blades last week...so, I'll reconfirm all the numbers to ensure 100% and then post the details of the manufacturer.[/QUOTE]

Thx Evanism;

I too have owned/used this machine for about 18 months - very happy with the results - seems a good balance of value and function until the blade change is required. Ran over a nail in some beautiful and very old Qld Hoop pine. Voila! instant feature stripes in 250mm Hoop Pine.

I had stopped by C-tec store in Brisbane earlier this year and asked after replacement carbide blades and was told they no longer stocked them as they were too expensive to sell!

I am not confident that sharpening 26 tiny pieces of HSS is a worthwhile task or even possible.

I would be very happy if you can publish your findings on compatible Carbide cutters. Good work

-

13th January 2015, 10:57 AM #39

New Member

New Member

- Join Date

- Aug 2013

- Location

- Airlie Beach, Queensland, Australia

- Posts

- 3

Any Info on the T-13s?

Any Info on the T-13s?

Hi all,

Does anyone have any experience with the Hafco T-13s ? I've seen plenty of discussion about the Carbatec C330x, but this thread is the only one I can turn up even referencing the Hafco model.

Right now (Jan 2015), the Carbatec C330x is $820 and the Hafco T-13s is $650 - so I'd be most interested to know if the Hafco is any good.

Cheers

Dan

-

15th January 2015, 06:07 PM #40

Intermediate Member

Intermediate Member

- Join Date

- Sep 2012

- Location

- AUstralia

- Posts

- 44

Hi mate, I have the T-13s and am very happy with it...

-

14th June 2016, 10:18 AM #41

Intermediate Member

Intermediate Member

- Join Date

- Jan 2015

- Location

- New Zealand

- Posts

- 48

Did anyone ever source less expensive /4 sided blades. I am thinking of buying a CT330X but the New Zealand price seems to be waay up there now at nearly $1200! price of blades mean I would have to sell my first born for a set.

Maybe there is something cheaper in the spiral/helical format that is more affordable..if so I'd love to hear.

-

14th June 2016, 11:36 AM #42

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

Unless a segment is badly damaged by a nail strike or similar they last for years and then only need rotation and not replacement.

CHRIS

-

17th June 2016, 06:39 PM #43

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2011

- Location

- Albury

- Posts

- 3,036

sje-tools, a member here does carbide inserts for a lot of the spiral head jointers/thicknessers at very attractive prices. I'm not sure if he stocks them for that model, but it couldn't hurt to send him a PM.

Similar Threads

-

Anyone know anything about this spiral cutter?

By Mark.Chambers in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 7Last Post: 19th October 2013, 09:05 AM -

Portable thicknessers Vs stationary units???

By Rattrap in forum JOINTERS, MOULDERS, THICKNESSERS, ETCReplies: 17Last Post: 17th July 2008, 02:34 PM -

Portable Thicknessers

By hitch in forum WOODWORK - GENERALReplies: 41Last Post: 22nd February 2008, 01:45 AM -

Flush cutter v Spiral cutter

By inferno6688 in forum ROUTING FORUMReplies: 9Last Post: 9th May 2006, 07:59 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote