Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 21

Thread: WIP Skew chisels for dovetailing

-

11th March 2015, 03:03 PM #1

WIP Skew chisels for dovetailing

WIP Skew chisels for dovetailing

Once upon a time there was a Forum's group buy for Stanley Plane blades fabricated in M2 steel. When we received the blades we got the adjuster slot cutouts as well. I've had 3 of these cutouts lying around for too long. It's time to either do something with them or throw them out.

Given the size I decided to try and make a couple of skew chisels for cleaning up when dovetailing. From reading various opinions a single fishtail would be more effective, but I've three pieces of steel, so what the heck.

I haven't got any high end metal working stuff, just an angle grinder, a Ryobi 6" grinder with grey wheels and some water stones. Here is the result of my hand shaping attempt so far using fingers and Jerry built holding jigs. Also an untouched slot cutout.

skewBlades.jpg

There will be a short intermission while I find somewhere to turn some handles since I got rid of my boat anchor MC900 last year.

BTW. M2 is tough stuff.

-

11th March 2015 03:03 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

11th March 2015, 03:37 PM #2

Wow you kept them for so long?

At least you have found a use for them.

-

11th March 2015, 10:18 PM #3

Those look pretty darn good for what was essentially freehand shaping, Fuzzie. I wouldn't be without the couple of sets of skews I've got, though I don't really know why I keep making skews, because a single spear-point chisel ought to do the job as well, and you wouldn't pick up the wrong skew, as I constantly do.

I did make a spear-point a long time back, & used it for a while, but ended up re-grinding that particular old chisel for something else, and making some skews, instead. I guess I was still in my "the more chisels you have, the better woodworker you must be", phase at the time, but I'm tending to try & reduce the number of tools I have, these days.

I did make a spear-point a long time back, & used it for a while, but ended up re-grinding that particular old chisel for something else, and making some skews, instead. I guess I was still in my "the more chisels you have, the better woodworker you must be", phase at the time, but I'm tending to try & reduce the number of tools I have, these days.

I shouldn't tell you this now you've gone & done all that work grinding the side bevels ( ), but you really didn't need 'em if you are going to use these for dovetailing. As long as the angle of the skew is equal to, or less than the angle of your dovetail, the points can get into their corresponding corners whether the sides are bevelled or not. In fact, they are a bit more robust if left straight-sided, imo (& Lee Valley seem to think so, too), so I leave my skews square-sided.

), but you really didn't need 'em if you are going to use these for dovetailing. As long as the angle of the skew is equal to, or less than the angle of your dovetail, the points can get into their corresponding corners whether the sides are bevelled or not. In fact, they are a bit more robust if left straight-sided, imo (& Lee Valley seem to think so, too), so I leave my skews square-sided.

A tip I've learnt the hard way over the years: it's best to keep the skew angle fairly shallow, or the point gets very fragile. This is even more of an issue with brittle steels like M2 (I used HSS for my latest pair, which is even worse!). About 20 degrees is plenty to do the job (unless you make very odd dovetails.. )

)

Cheers,IW

-

12th March 2015, 12:29 AM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

I've been in the market for a couple of skews for a while now. I keep waffling between buying a snazzy pair from someone like Lie Nielsen or going a cheaper route. Given that I have literally the same tools you have, maybe it's time to stop shopping and start shaping!

Well done, by the way!

-

12th March 2015, 10:27 AM #5

Hi Ian,

This is more an exercise in basic metal working rather than creating the perfect dovetail chisel. Up until now I have been using an 1/8" chisel to clean out the corners of my half lap pins and found that quite satisfactory, so this is pure experimentation. I decided to bevel the edges of the blank mainly because at 3.5mm thick it somehow didn't fell right. For comparison the narrow square edge Titan that I have is slightly tapered and at about 2.7mm at the business end feels much nicer in the hand and I'm guessing helps see where it is steering in a cut.

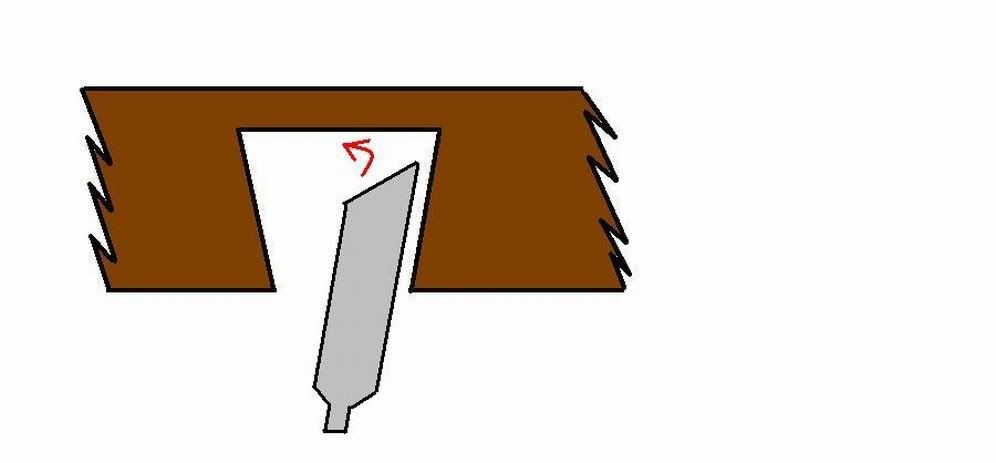

Luke, here is the holder I hacked up to hold the blade against the wheel. It is just a thin piece of pine with a slot cut at the end to slide the blade in. I chamfered the edge that approaches the wheel, but I found the single countersunk machine bolt didn't really give enough holding power. If I did it again I would use two.

holder.jpg

I used a 1mm disk in the angle grinder to cut the tip at an angle and shape the tang freehand, before grinding.

Cheers, Franklin

-

12th March 2015, 02:00 PM #6

Fuzzie, I didn't mean to be hypercritical, my observation re the bevels not being essential was more for the benefit of others who might want to make some dovetailing skews, & might shrink from that step. I can easily understand the desire to play about a bit with the shaping for aesthetic more than practical reasons, being just slightly prone to such temptations, myself.

As you've demonstrated, shaping metal doesn't necessarily need terribly sophisticated gear or jigs to get a pleasing result, but as I found when making a couple of mini BE chisels from HSS, it does take a bit of care to get things neat & symmetrical. I gave up on the smaller one & finished the bevelling with diamond files which was a bit tedious. I was impressed by how well you did on a first try!

As you've demonstrated, shaping metal doesn't necessarily need terribly sophisticated gear or jigs to get a pleasing result, but as I found when making a couple of mini BE chisels from HSS, it does take a bit of care to get things neat & symmetrical. I gave up on the smaller one & finished the bevelling with diamond files which was a bit tedious. I was impressed by how well you did on a first try!

Luke, you can get pieces of high speed steel in sizes suited to making small skews from McJings. HSS is tough stuff to work with, but it has the advantage that if you are a bit over-enthusiatic on the grinder & 'blue' it, you won't soften it as you would for less heat-resistant hardened steels. But it is a bit on the brittle side, so don't make your points too long & fragile..

Cheers,IW

-

12th March 2015, 02:46 PM #7

Member

Member

- Join Date

- Feb 2014

- Location

- Sydney

- Posts

- 70

I have managed to (very slowly) re-grind a 8mm Aldi chisel into a fish tail for half blind dovetails using just a dremel.

I didn't put a bevel on the edges, as i only wanted it for cleaning up the waste. As long as you have a contain of water near by and keep dunking it - its fairly easy to do - if time consuming.

I'm sure proper store bought skews or fishtails are much much better - but for me this accomplishes what i need. I recon eveyone should give it a go

-

12th March 2015, 04:31 PM #8

It has been passing my mind to make an attempt at a fishtail if these ones work out OK. I've got a few spare plane irons of a variety of styles that could be sacrificed for the project to make longer and wider blades. My main concern is how to fashion the blank. Freehand cutting with the angle grinder is unlikely to yield a pleasing result and I'm sure the heat issue would be a problem on the carbon steel irons.

-

12th March 2015, 07:41 PM #9

Aha, I'm glad you gave us that reference, Fuzzie. I was jumping to (wrong) conclusions, as I often do! I see you really do mean a fishtail chisel, but for some silly reason, I was imagining you were actually referring to a 'spear-point' chisel. Perhps that's because if I wanted a single chisel that could clean up both sides of a 1/2-blind D/T socket, I think I'd prefer a 'double skew' or spear point over the fishtail design. You would need a chisel with quite a narrow end, so that it can fit it into a small socket (though perhaps you cut much wider sockets than I usually do). My most-used skews are the 1/4" & 3/16" pairs, which probably tells you what size sockets I most often cut. So I guess this is why I was thinking a spear point design would be better alternative, i.e., a chisel sharpened as a 'double skew' forming a point in the centre. With something like that, you could get into both corners of a socket, and be able to take advantage of the easier shearing cut of the skewed edges for trimming the bottom of the socket, which is something I use my skews for, as well as cleaning the corners.

Just a thought....

CheersIW

-

12th March 2015, 08:51 PM #10

Ian I'm having a hard time visualizing your dovetails, mind you I've only made a small number of dovetailed drawers in my life. My drawer sides have either used pins and tails of about the same size or pins much smaller than the tails. I'm only imagining these blades used for cleaning the sockets between the pins in a single lap layout, cleaning up to the back wall and getting into the corners. With skews you would need to use three chisels on each socket, a left and right skew to get into the corners and a normal chisel for cutting into the endgrain at the rear of the socket. With a fishtail like the Blue Spruce ones (they only seem to make two - a 1/2" and a bit smaller) you could clean up most sockets with the one chisel moving from side to side in one pass of the chisel, but maybe for really small pins you might use a wider bench chisel to tidy up to the back wall as well.

-

12th March 2015, 08:59 PM #11

Ian, a spear point is good. I agree. I have a couple from Chris Vesper. These work excellently as a marking knife and are useful for clearing out half-blind dovetails ...

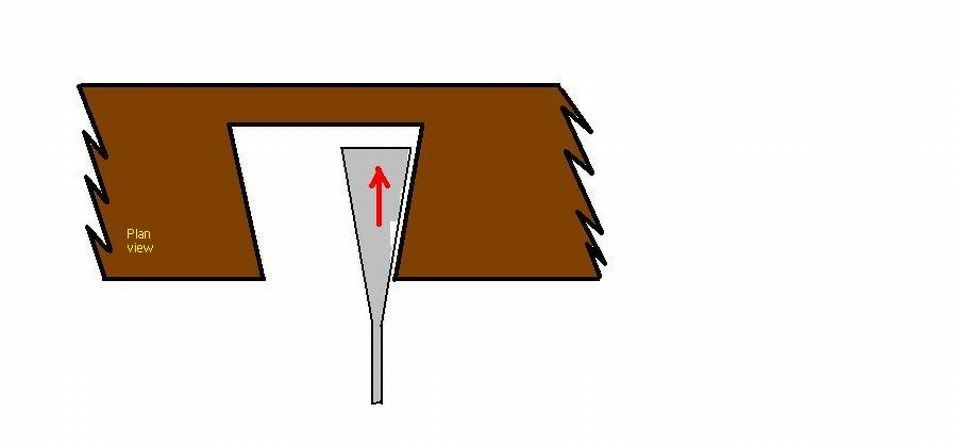

I still prefer a fishtail chisel, however, and even over a skew chisel. Here is a fishtail I made a good many years ago now ..

It is interesting that Fuzzie linked to the Blue Spruce fishtail chisels as there is a story there. Dave Jeske (BS) was only interested in making skews, and we got into a conversation. Below are the pictures I sent him at the time. The remarks about them apply equally to a spear point chisel/knife.

The skew chisel (spear point) works very well to get into a corner and clear out the waste, however you need to apply a slicing action for it to work ...

On the other hand, a fishtail chisel simply requires forward pressure to cut, which involves less twisting of a wrist and has more controlled power ..

When Dave began making them, I purchased a couple of Blue Spruce fishtail chisels.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

12th March 2015, 10:25 PM #12

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

Franklin, if you want to make reasonably even side bevels have a look at the jig I use in this post.

https://www.woodworkforums.com/showth...460#post855460

-

13th March 2015, 10:22 AM #13

Yep, it's only small sockets where you need small skews/fishtails/spear points, whatever turns your crank. For large dovetails like on a carcase piece, I would use the original 1/2" pair I bought from Lee Valley back when they first offered them (& a very good price they were then, too!). Lately, I seem to be cutting lots of teeny dovetail sockets, too small even for the 1/4" pair I made, so I made some even smaller skews a while back.

It's always interesting to see the different ways we solve the same or similar problems. For donkey's years, I used a thin paring chisel for cleaning sockets (as we did at school). It's easy enough to clean the sides & back with a straight chisel, & if you cut thin slices, you can flick these out of the corners easily enough, and get a socket that is good enough to do the job. What you can't do with a straight chisel is pare the bottom of the socket neatly into the corner, like you can easily do with a skew. I find the slicing action of a skew easier to control, & it gives me a much cleaner finish than the straight blade on a normal chisel or a fishtail, on soft woods like Red Cedar, for e.g. In fact, the slicing ability was touted as one of the big pluses of a skew when LV first offered them.

I can see an immediate advantage in the fishtail, in that you only need the one chisel of a size suited to the size of the socket. Picking up first one, then the other, skew when cleaning out a carcase-side's worth of sockets gets to be a chore. In moments of laziness, or when I pick up the wrong skew by mistake, I will use the same one for cleaning out both corners, though the bevel makes it awkward to cut neatly in the 'wrong' corner, and trying to pare the bottom of the corner bevel-down usually ends with either a dig-in & a large chunk removed, or a broken point and a few choice words of self-recrimination. . So skews are not without their own idiosyncracies. The only fishtail I have is a small carving chisel, and the end is slightly curved on that, & it's not really suited to cleaning D/T sockets, but I haven't made a chisel for at least 6 months, so maybe it's time to make myself a fishy one, & give it a proper trial....

. So skews are not without their own idiosyncracies. The only fishtail I have is a small carving chisel, and the end is slightly curved on that, & it's not really suited to cleaning D/T sockets, but I haven't made a chisel for at least 6 months, so maybe it's time to make myself a fishy one, & give it a proper trial....

Cheers,IW

-

25th March 2015, 05:01 PM #14

I pruned back an old Grevillea Moonlight a few years ago and it has been patiently waiting in my shorts bin since then. Yesterday I had the opportunity to have a go at turning it into some handles at the local men's shed. Unfortunately ran out of time, but here's a start. The second pic has some meths splashed on for an idea of the colour. The shape is beginning to approximate the handle of my old Marples Shamrock Brand 1/8" bevel edge.

shape1.jpgshape2.jpg

-

31st March 2015, 06:10 PM #15

Set and finished with a coat of BLO.

skews.jpg

Similar Threads

-

Japanese Chisels - which to buy, dovetailing and general use

By zilberi in forum JAPANESE HAND TOOLSReplies: 0Last Post: 1st April 2014, 03:52 PM -

Choice of skew chisels

By jefferson in forum WOODTURNING - GENERALReplies: 3Last Post: 14th June 2008, 07:34 PM -

Lie-Nielsen Skew Chisels

By Mirboo in forum HAND TOOLS - UNPOWEREDReplies: 4Last Post: 25th November 2006, 01:30 PM -

Damn skew chisels

By Toggy in forum WOODTURNING - GENERALReplies: 16Last Post: 21st December 2004, 10:00 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote