Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 31

Thread: Bifold Doors ?????

-

18th January 2007, 04:43 PM #1

Intermediate Member

Intermediate Member

- Join Date

- Aug 2005

- Location

- Sandgat4e

- Posts

- 37

Bifold Doors ?????

Bifold Doors ?????

We are about to attempt to install our bifold doors, but Im not sure what we should be using to frame around them. I have the doors there are six which are WRC and glass and I have ordered the tracks from Cowdroy

and the hyspan beam for the lintel but Im not sure what we should be using for framing the doors as in size and type of timber. With the bottom guide rail I know it can be rebated but no idea what size etc we should be using for this. The doors are 705mm each and there are six of them and they are around 2230 high.

and the hyspan beam for the lintel but Im not sure what we should be using for framing the doors as in size and type of timber. With the bottom guide rail I know it can be rebated but no idea what size etc we should be using for this. The doors are 705mm each and there are six of them and they are around 2230 high.

Ive asked around but getting nowhere fast and Im just getting more and more confused with where to start with the things and would really appreciate any advice.

-

18th January 2007 04:43 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

18th January 2007, 05:10 PM #2

Intermediate Member

Intermediate Member

- Join Date

- Aug 2005

- Location

- Sandgat4e

- Posts

- 37

The hyspan beam which our draftsman has said to use is 300x63 do you think this is ok for the span of 5 metres. I dont like to doubt but have been told a few times our draftie is a bit vague with some of the stuff hes put on the plans.

-

18th January 2007, 05:15 PM #3

Hi There ... not sure about the bi-folds ... are they to be painted? If so then I guess you would use hardwood like a door jamb? If they are something like WR cedar then you probably want a specialy matching timber.

I think there is a bit of an are to getting any doors let alone bi-folds right ... so take your time and be careful.

As for the beam ... I don't think anyone will be able to answer unless you give more detail about what it is supporting. Tiled roof, second storey, flat / pitched etc.?

-

18th January 2007, 05:45 PM #4

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

It depends on what look you want to achieve. I've just built a couple of sashes and six glazed doors out of hardwood at 770 X 2500 and I've hung them as bifolds. I used a Hyspan over the opening as well. I've gone into detail about the project here. I wouldn't bother with a bottom guide rail but you might prefer one. The frame size is only what you need to screw the hinges in so long as it's fixed to something. If the first leaf is pivoting then you don't need any timber, or just what you want for a rebate. If you like more timber then get a jamb the width of the wall and put architraves on it.

How much did the doors and track set you back?

-

18th January 2007, 06:16 PM #5

Intermediate Member

Intermediate Member

- Join Date

- Aug 2005

- Location

- Sandgat4e

- Posts

- 37

The hyspan will only really be supporting the doors .We have lifted the house up and there is a 250pfc supporting the upper level which is around 3metres above the floor level so we need the hyspan to put at the door height I think to set the tracks etc on.

Your doors you made are excellent they look fantastic and gosh if only we were that skilled.

The doors cost us $900 from the auctions ,they are a stegbar door and have quite a dark tint on the glass thankfully as we get full afternoon sun. The tracks after much hunting around Ive decided to go with Cowdroy which are costing around $750 all up which is top and bottom pivots, hinges etc I dont think it includes any bolts. I looked into Centaur as I was told they were the better ones but they were going to cost around $1700 and that would have blown the budget way out.

I really like the way your track etc is sunk into the gyprock I was thinking we had to have some sort of timber frame. With the top track if we try to do similar to yours does it then just attatch straight to the hyspan or does it go onto some sort of framing timber that butts onto the hyspan.

-

18th January 2007, 08:39 PM #6

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

Well If the pfc can carry the weight then you could just bolt the frame up to it using a few lengths of threaded rod. In your situation I would have set the beam at whatever your door height was and framed on top to support the upper floor but I don’t know what the beam was designed to carry.

Thanks for that. I’ve been a chippy builder for over twenty five years so I thought I’d tackle a first and build some doors since to have custom jobs made would have cost about $5K or more.That’s a good price. I was thinking about buying some glazed doors that I saw from Doors Plus for about $130 per panel. I think they’re some sort of maple but they’re just a standard size and I wanted high doors.Yeh, that’s what I found. They’re pretty expensive for what they are.

I’ve just worked out how much mine cost me. The track was $66, the stainless hinges (four on each door, two on each window) and screws were $120. I had the carriages already but I’m sure you could make something up with a bit of stuffing around for not too much $. The flush bolts were $14.50 each X 4 = $58, the mortice bolts were about the same = $58, The keyed handles were $20 X 2 = $40 , the aluminium angle on the floor was $13 and the cabin hooks were virtually free at 80c each from Big W (good for a lot of hardware and tools). So that’s about $357 for all the furniture.

The timber was $605, the glue was $41 the glass was $480 and silicone and glazing bead nails were probably about $15, so that’s $1141 for the doors including the two windows and framework, making $1498 all up not including the supporting bulkhead which is never a part of any door system quote, and not including stain and polyurethane.

The labour was priceless.

Tell us what system you're getting and I’ll have a look at it. They usually intend you to install the track under the beam (unlike mine), and the track will probably run the full length of the opening (unlike mine). You just screw it up into the beam, or through a jamb and into the beam with some long screws. It will come with a bottom track and guide as well and they won’t have been intended to fold back flat against the wall. There’ll be a big stack of doors in the opening sticking out perpendicular if you configure it the way it’s intended.

There’ll be a big stack of doors in the opening sticking out perpendicular if you configure it the way it’s intended.

-

18th January 2007, 09:20 PM #7

Intermediate Member

Intermediate Member

- Join Date

- Aug 2005

- Location

- Sandgat4e

- Posts

- 37

I have ordered the Heavy Duty Triumph multi folding 60kg per leaf.

Id love to be able to make something up ourselves like you have but believe me it is way beyond us even trying to do this is a major.

Appreciate your time too many thanks

-

20th January 2007, 12:19 AM #8

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

No problems.

As for your Triumph bi fold system,,,

Hmmm,,,.

I installed a system about ten years ago with an identical design and I hope I never see one again. I won’t slander Cowdroy because I can’t remember who manufactured it but this is what I found when I installed it and I can see the same problems may occur with this system.: -

1. The pivoting system was inadequate and it deflected towards the middle of the opening when the first door was hung and closed. It deflected towards the outside when the door was opened. When the second door was hung it fixed up the problem of deflection towards the middle but it still deflected towards the outside when open. They say in the brochure that the guide track is optional, but I reckon that without it the problem would be compounded. I wouldn’t have rated it at 60kg but it probably would have been alright for a hollow core internal door, however in my opinion the whole design of the pivoting system was inadequate. Because of the outward deflection at the top of the door I had to lift the doors giving a huge gap underneath so they’d clear the floor when open and if it deflected any more after I’d gone then they would have had to crank them up even more. I can imagine the same thing happening to this system after looking at it. That top pivot simply does not look strong enough to me but I may be wrong. With a hinged first panel system you don’t get that problem at all. The jamb holds everything straight. Unfortunately you can’t use hinges with this system unless you employ unequal door sizes.

2. There’s no central support for the jamb leaf so it’s free to bend and warp if it wants to. They say you can use a 3 metre high door but if it’s a timber door then you’d better cross your fingers and pray that it’s straight and it stays that way. I’ve seen some doors of that height with quite large bows in them in my time. If it's bowed then you may have to leave a huge gap at the side of the door or it will jam when you try opening it. If your opening is already a fixed size then you'll have to remove the door and all the fittings then plane it down or plane a big ugly bevel along the end. If it bows after it's installed then it will jam up and you'll have the same headaches. This is not a problem at all with a hinged system.

3. With the pivot set back 55mm from the edge of the door it means that the door swings slightly inwards so you can’t have the door close hard against a jamb at the top or the sides, or an angle on the floor. You’ll have to put up with a gap that the wind blows in unless they have some magical way to overcome this that I haven’t thought of.

4. With the pivot set back 55mm from the edge of the door, and with a flimsy 3mm mounting plate the optional end fixing bracket would be useless and you’d be relying totally on the top fixings. You’d better put some really long screws in because if the door starts perishing in the weather it will fall off. They have an optional side fixing bracket to overcome this and give it more strength so long as you like looking at a big ugly plate screwed to the face of the door. It’s chrome so if you want to match it with the rest of your furniture you’d have to get chrome not brass or stainless. I’d imagine the screws would be very noticeable unless they were chrome as well.

5. You have to leave a big gap over top of the door to get to the adjustment locking bolt.

6. You have to take the door right off the carriage to make any adjustments. If you get it wrong you have to take it off again until you get it right

IMO this design is no good and I’d never buy one. I've hung thousands of doors quickly and I had to stuff around with these for ages just to get them to work, let alone try to minimise the look of all the gaps I ended up with and it still looked dodgy. I can't imagine how long it would take a handyman if he doesn't butcher it in the process.

If I had one already I’d throw the pivots in the bin and hinge the first leaf. I’d bend the carriage mounting bracket at 90 degrees so it provides end fixing as well as bringing the pivoting point close to the edge of the door. Then I’d cut the track and install it on an angle so I wouldn’t have to use unequal door sizes, otherwise it wouldn’t even open very far at all before they jammed up. That would fix all the problems that I can see with it. I’d like to see their installation manual (if they’ve got one) and see what they’re proposing for all the gaps you’d end up getting.

That’s just my two bobs worth but I’d try to get my money back if I were in your shoes. Then I’d go out and buy one of these. I was quoted $660 for a set up with all the tracks and hinges but without bolts and locks. I can tell by just looking at it and studying the brochure and the installation manual That it’s by far a superior product with an excellent design that would have none of the problems of a pivoting system. Even the adjustment system is superior in that you don’t have to leave any gap above the door to get a spanner in like you do with the Cowdroy system, and you can adjust them whilst they’re hanging with just an ordinary screwdriver not a specific sized spanner. This is a desirable feature with timber doors that may move over time. It’s rated at 40kg but I’d trust it a hell of a lot more than putting a 40kg door on that 60kg system above. Your doors would be well under 40kg if they were cedar I’d say. I’d guess that my 2500 hardwood doors would come in at a bit under 40kg as well but that would be guessing. I haven’t had to lift them since they’ve been glazed but the frames are pretty heavy and the glass isn’t all that light either.

If you’ve never hung a door before you may find all that a bit confusing. I’m happy to try to explain my points in more detail, perhaps with diagrams.

-

20th January 2007, 03:59 PM #9

Intermediate Member

Intermediate Member

- Join Date

- Aug 2005

- Location

- Sandgat4e

- Posts

- 37

Wow thanks so much for all that info I really do appreciate the time you have taken to do that.

funny as today I went to buy some hinges and they had all the centor products there and they were not that much more expensive as I had orignally been lead to believe. Thanks heaps and after your information Im going to try and get my money back on the other system , hopefully they will be ok as they are not being delivered untill next week so shall try my hardest but Im so glad you have kindly pointed everything out as honestly I would not have had any idea whatsoever on what you have picked up and if we have to spend a few hundred more for a much better product Im happy to do that.

Ill let you know how I go. Fingers crossed

-

20th January 2007, 06:32 PM #10

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

Thanks for that. You can give me a brownie point if you want: -

Thanks for that. You can give me a brownie point if you want: - Originally Posted by Pantotango

Originally Posted by Pantotango

I tried to buy just the two carriage hinges and a bit of track from Centor but they wouldn’t break up a set. Oh well, that’s their loss since I just made up my own superior system for a quarter of the cost. A bit more labour intensive though. But I’m not too worried about a bit of my spare time if I get a good looking job out of it. Originally Posted by Pantotango

Do that. I’ll help you out as much as I can.

Originally Posted by Pantotango

Do that. I’ll help you out as much as I can. Originally Posted by Pantotango

Originally Posted by Pantotango

Be careful setting out the opening size. It’s not like hanging a single door where there’s just one measurement. Your errors will be compounded with six doors and it’s always an apprehensive moment when you hang that last door and check out the clearance you get in the middle. It’s not often perfect but there’s plenty you can do to tune them up a bit (checking in the hinges or packing them a bit, planing down a leaf or two, adjusting height etc.). If you’ve got a long wall that you can lean all the doors against, then push them all together tight. See how they fit together and plane them so there’s no gaps between them. Measure the overall width and make allowance for the clearance between each leaf. With the Centor system the hinges are non-mortice so they’re easy to fit. You don’t have to chop them into the door, and the clearance between the leaves will be the thickness of the hinge. It will be the number of doors plus one, so in your case it will be 7 X hinge thickness + doors. If your doors are all square edged then you can rebate the middle two but allow for that in your measurements. Alternatively you can nail a cover strip on one of the doors from the outside. It will still look neat, you won’t have to make rebates and the door rails will look the same width from inside and out. A way of interlocking the other gaps between the doors is to router a semicircular groove in the edge of interlocking doors and insert a dowel in one of them, but that’s not really done anymore. A seal system is more weather tight and from looking at the installation instructions, Centor has a good rubber seal system that inserts in a saw cut in the edge of the doors. I just used a foam stick on weather seal from Raven. It's pretty cheap for a fifty metre roll, but I was impatient and bought a heap of 6 metre packets from the hardware (I forgot to add that in my costs. I'll dig up the receipt).

If you don’t have a long wall, then just number the doors and test their fit to each other one at a time. Check the measurements top and bottom to make sure that you're not planing the doors to a wedge shape. Be very carefull that the opening is dead plumb and level all around. I’d recommend a water level and a plumb bob. The simplest devices are the most accurate sometimes. A bashed up spirit level and dumpy level can’t be trusted as much. I wouldn’t even trust a brand new one as much as I trust Isaac Newton and the laws of gravity.

That Hyspan of yours may be unnecessary as well as I’ve already mentioned. It’s easier and cheaper to just frame it up to the PFC and put in some booker rod (threaded rod) rather than installing a big expensive beam, but as I’ve mentioned I don’t know if it can carry the weight of three doors (though you have six, it’s only really carrying three). Less than 100kg I’d say.

edit: - Ah, I've just realized that you've jacked the house up and that's what the PFC is for. I wasn't paying attention there. I wouldn't worry about the Hyspan if it were me, but technically you should get an engineer to do the calculations. He''ll probably allow for the weight of all the doors rather than just the three that the PFC will be carrying.

-

23rd January 2007, 07:33 PM #11

Intermediate Member

Intermediate Member

- Join Date

- Aug 2005

- Location

- Sandgat4e

- Posts

- 37

Hi again. Stuck again I am . Not good what a headache when your not sure of what your doing.

So Ive decided on Centor tracks I have abit of a print out with what is needed etc but dont know what to order in the way of framing and for the sill etc. They do their own sill which I dont want just the chanel but not sure what we use for the head jamb they have on the specs it should be 68mm and we sort of worked out it should be around well I think 140mm does that sound right or am I off track.

Thanks again

-

23rd January 2007, 09:37 PM #12

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

It depends on what look you want.

Do you want plaster set reveals like mine, or do you want a timber reveal with timber architraves on the inside?

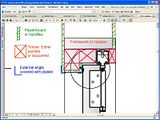

They have a pretty good diagram of what's going on in their installation manual here: -

But there's no dimension that I can see for the depth of the track.

I can draw up a plan of options of how it could be done if you tell me what look you want.

-

23rd January 2007, 10:07 PM #13

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

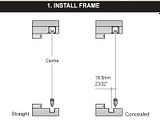

As for the bottom, you have two options by the look of things. Maybe there's a different type of bottom guide for each. One is a concealed option where the track sits under the door when closed, and with the other it sits outside the door.

How you install it depends on what's there. Is it concrete or tiles or timber? Will there be a deck outside or a concrete patio?

-

24th January 2007, 08:43 AM #14

Intermediate Member

Intermediate Member

- Join Date

- Aug 2005

- Location

- Sandgat4e

- Posts

- 37

I actually really like the plaster like yours I hadnt thought about that option but when I saw the photos of your doors I prefer it compared to the timber showing.

At the bottom for the moment we only have particle board and not too sure with what we will be using tiles or timber for the flooring . There will be a timber deck off the doors eventually as well.

I was looking at the bottom options and think the concealed would be better.

I think you must have at least 10 brownie points by now

thanks heaps

-

24th January 2007, 09:14 AM #15

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

Similar Threads

-

Bookcase with Bifold Doors WIP

By Studley 2436 in forum WOODWORK PICSReplies: 17Last Post: 23rd May 2006, 09:57 PM