Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 63

-

12th March 2009, 01:13 PM #1

Golden Member

Golden Member

- Join Date

- Oct 2006

- Location

- Dandenong Ranges

- Age

- 47

- Posts

- 816

Woodworking short courses -Building A Hall Table

Woodworking short courses -Building A Hall Table

Hope I'm not breaking any rules here (advertising wise), but I just found out about the courses running at Ideal Tools with Terry Fogarty. I've booked in for the hall table course, wondering if anyone else is doing the same?

Have I made a good decision? Help me reinforce my purchasing decision by saying "yes!"

Last edited by watson; 26th May 2009 at 06:52 PM.

___________________________________________________________

"The things I make may be for others, but how I make them is for me."

-

12th March 2009 01:13 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

12th March 2009, 08:52 PM #2

Can't speak for the classes but Terry seems like a prolific maker...

If he can teach as well as he can build then you'll be in for a good time.

Good LuckSteven Thomas

-

13th March 2009, 04:33 PM #3

wood butcher

wood butcher

- Join Date

- Dec 2008

- Location

- East Bentleigh

- Posts

- 200

It looks like a good course. I'd love to attend if someone else would like to pony up the cash? I've just spent the last of mine (approved the the domestic financial controller) on a Carba-tec table saw and band saw. (very excited about their pending arrival).

-

13th March 2009, 05:10 PM #4

Golden Member

Golden Member

- Join Date

- Oct 2006

- Location

- Dandenong Ranges

- Age

- 47

- Posts

- 816

Those purchases will keep you very busy for a while I think!

I've been very lucky with the financial delegations lately so I'm using it up before it gets snatched away from me! Table saw, dust extractor, this course and few small accessories. Probably be the last time this year I'll be able to spend any I think!___________________________________________________________

"The things I make may be for others, but how I make them is for me."

-

9th May 2009, 05:18 PM #5

Golden Member

Golden Member

- Join Date

- Oct 2006

- Location

- Dandenong Ranges

- Age

- 47

- Posts

- 816

Building a Hall Table course ...

Building a Hall Table course ...

Well, we just had our first session of the Building a Hall Table course. Terry posted some photos of his sample that he brought in to show us. It's really a fantastic piece in the flesh (although us clever students decided to pick up on a few other "features"!

)

)

5 of us in the class (including Anthony) + Terry.

We spent a fair bit of time learning about the rough pieces of timber and getting the legs docked, jointed and thicknessed. We had to improvise a little with the tablesaw because the jointer wasn't working 100% accurately. This was actually really intersting to me because I'm unlikely to buy a jointer in the near future so learning how to use other tools to do similar jobs was useful.

I didn't manage to take many pics but here are a few. Hopefully will take many more next week.

Cheers,

Af.

P.S. Could one of the mods change the title of this thread to "Making a hall table course" or something like that? Thanks.___________________________________________________________

"The things I make may be for others, but how I make them is for me."

-

12th May 2009, 06:18 PM #6

Golden Member

Golden Member

- Join Date

- Oct 2006

- Location

- Dandenong Ranges

- Age

- 47

- Posts

- 816

I've been playing around with some design options for my hall table. At the moment, I'm focusing on the sides as we're working on that next week.

What do people think? Which might work better and which do you think might be more feasible build/skill wise? Also keen to hear any other ideas you may have.

Option 1: A touch art-deco inspired

Option 2: A bit more straight forward

Option 3: Some more detail where the verticals overlap the side rails

Cheers,

Af.___________________________________________________________

"The things I make may be for others, but how I make them is for me."

-

13th May 2009, 03:26 PM #7

.

.

- Join Date

- Jul 2005

- Location

- Victoria

- Posts

- 5,215

Great designing Afro. I like the first one

. Thatís a ripper. Three 26 x 8mm rails at the bottom, and the same size joining the bottom side rail tapering to around 40mm at the top would create a lovely fan effect. They would also look great Ebonised (stained black)

. Thatís a ripper. Three 26 x 8mm rails at the bottom, and the same size joining the bottom side rail tapering to around 40mm at the top would create a lovely fan effect. They would also look great Ebonised (stained black)

-

13th May 2009, 09:35 PM #8

Golden Member

Golden Member

- Join Date

- Oct 2006

- Location

- Dandenong Ranges

- Age

- 47

- Posts

- 816

Thanks for the tips Lignum. I've been playing with your idea. Here's what I think you're describing ...

Option 4

How I join it all up is another question but we'll deal with that afterwards I guess. Do you think I should space them out a little wider?

Do you think I should space them out a little wider?

Cheers,

Af.___________________________________________________________

"The things I make may be for others, but how I make them is for me."

-

16th May 2009, 05:36 PM #9

Golden Member

Golden Member

- Join Date

- Oct 2006

- Location

- Dandenong Ranges

- Age

- 47

- Posts

- 816

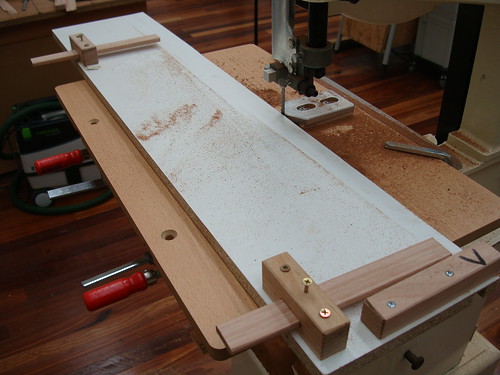

This morning we worked on the front rail, the one with the drawer insert. Terry showed us a nice way to rip the rail into three pieces, cut out the drawer front, then piece it back together. Saw kerf aside, if you can match the grain nicely back together, then it should look quite seemless.

Here are my three pieces with the drawer cut...

I then got to play with the Domino. Second time I've used it now and I really do love it. Just waiting for a weak moment from LOML before I snap one up for myself!

And then the glue-up of the front rail ...

Cheers,

Af.___________________________________________________________

"The things I make may be for others, but how I make them is for me."

-

23rd May 2009, 06:24 PM #10

Golden Member

Golden Member

- Join Date

- Oct 2006

- Location

- Dandenong Ranges

- Age

- 47

- Posts

- 816

Hope I'm not boring anyone with these updates! I'll just keep on going until I get told to shut up!

Today was a fun day. I'm quite surprised at how varied the learning is and how much I am learning through this. Today we focused on two things, tapering & cleaning the legs, and sizing/docking the side & back rails. I started with the legs.

We got to use the Frontline jig that Lignum described in another thread. This one has a straight channel in the bottom which slots onto the Frontline bearings. The jigs on the top are quite neat and simple. Just align your leg for the taper and screw the jig down in place. Then, all your leg tapers will be exactly the same when you run them through the bandsaw.

Here are my tapered legs fresh off the bandsaw and yet to be cleaned up on the jointer.

I then got to use a scraper for the first time. I was always suspicious of you folk who rave about how awesome this stupid little bit of simple metal is. I am no longer suspicious, but wonder why I didn't try it earlier. I'm converted!

Aside from the burning thumbs, it's really quite nice and easy to use. Safe too (in a "don't destroy your work" kinda way). I made plenty of whispy shavings with it and managed to get rid of some small bits of tearout and scratches with ease.

In-between all of this, we ripped and docked the side and back rails to size. Here are all my pieces so far (legs hiding at the back).

More photos on my flickr feed below for those interested.

Cheers,

Af.

___________________________________________________________

"The things I make may be for others, but how I make them is for me."

-

30th May 2009, 08:24 PM #11

Golden Member

Golden Member

- Join Date

- Oct 2006

- Location

- Dandenong Ranges

- Age

- 47

- Posts

- 816

No complaints? I'll keep on rambling on then!

Today was a busy day. Mostly left to do all the joinery for our top rails and legs. I finished up with making and joining the bottom rail too. The bottom rail was tricky because of the inner taper on the legs, but I eventually got there!

First dry fit:

My first mistake:

Misplaced the mortise for the table top buttons. Easily fixed though and thankfully it's hidden on the back of the rail so no-one will see it (except all you folk!)

Easily fixed though and thankfully it's hidden on the back of the rail so no-one will see it (except all you folk!)

Bottom rails:

Took me a few shots to get the angles right, but I'm pretty happy with the final dry fit.

Cheers,

Af.___________________________________________________________

"The things I make may be for others, but how I make them is for me."

-

30th May 2009, 09:08 PM #12

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2008

- Location

- Perth

- Posts

- 966

Keep em coming. Very interesting.

-

30th May 2009, 11:13 PM #13

-

30th May 2009, 11:50 PM #14

Afro,

Good work buddy. You are going to learn a lot for Terry because he is very clever man.

You probably have the nicest workshop we've seen here. Don't worry it is not your fault. Hmm those floor boards are nice, very nice.

Visit my website at www.myFineWoodWork.com

Don't worry it is not your fault. Hmm those floor boards are nice, very nice.

Visit my website at www.myFineWoodWork.com

-

31st May 2009, 12:12 AM #15

Similar Threads

-

Short woodworking courses in Sydney?

By enna in forum WOODWORK - GENERALReplies: 5Last Post: 1st December 2008, 05:18 PM -

Woodworking Courses

By notrot in forum WOODWORK - GENERALReplies: 10Last Post: 7th September 2005, 09:51 PM -

beginner woodworking courses??

By Jodeem in forum WOODWORK - GENERALReplies: 6Last Post: 16th August 2005, 10:54 AM -

Woodworking courses

By Pat in forum WOODWORK - GENERALReplies: 2Last Post: 21st September 2004, 09:42 AM -

Short Courses

By David Fowler in forum WOODWORK - GENERALReplies: 1Last Post: 24th November 1999, 07:49 AM

Reply With Quote

Reply With Quote