Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 4 of 4

-

22nd January 2011, 05:10 AM #1

New Member

New Member

- Join Date

- Jan 2011

- Location

- Sydney

- Posts

- 7

Beginner questions for my first project. (arcade game cabinet)

Beginner questions for my first project. (arcade game cabinet)

Hi,

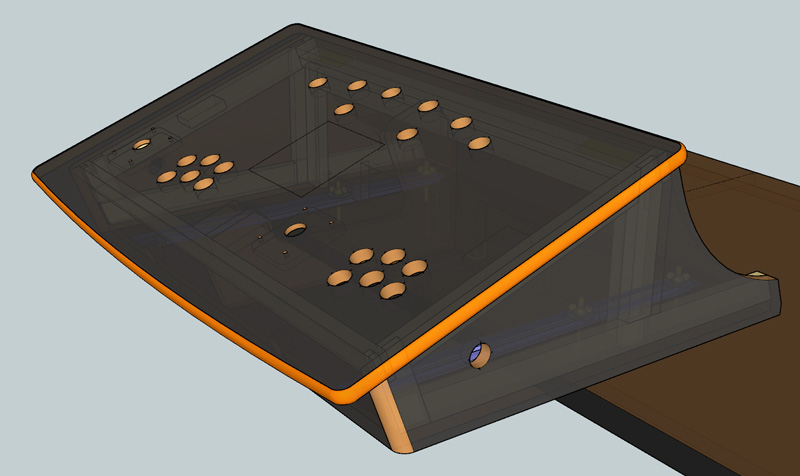

I'm a newcomer not only to these forums but also to woodworking, so I'm more or less clueless. I'm making a box to house arcade machine controls that is a little bit "special" and have spent the last week or so browsing this and other sites for tips while planning things out in sketchup. Here's what I have so far:

It sits on an existing table in front of a wall mounted TV. The blue rails and wingnuts on the base are so it can be pulled out like a drawer, overhanging the table edge, or slid back when not in use, or removed completely if we want to use that table as a table.

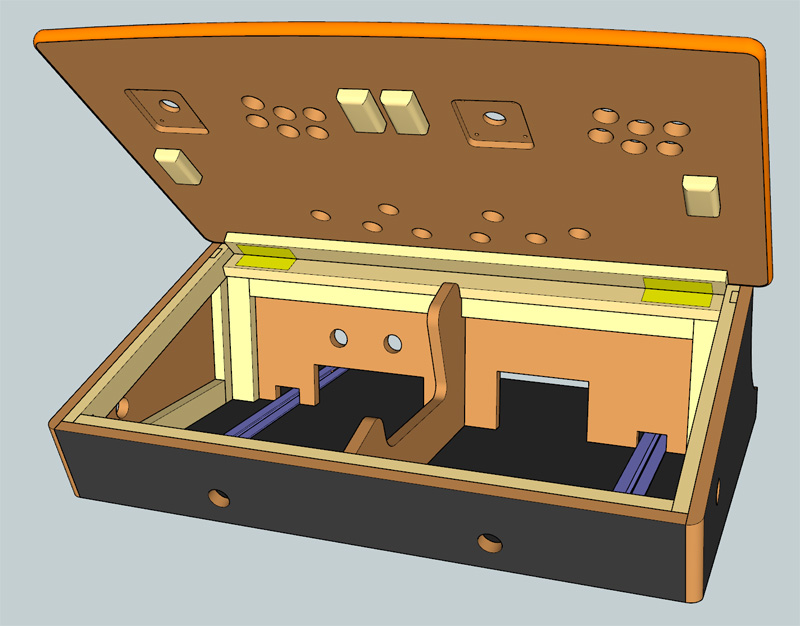

The plan is to use 42x19mm pine for the structure and 18mm MDF for the panels. Heavy and sturdy is good, but I understand MDF is not the best at taking screws, so the framework is maybe a little over the top. Maybe other materials would be better?

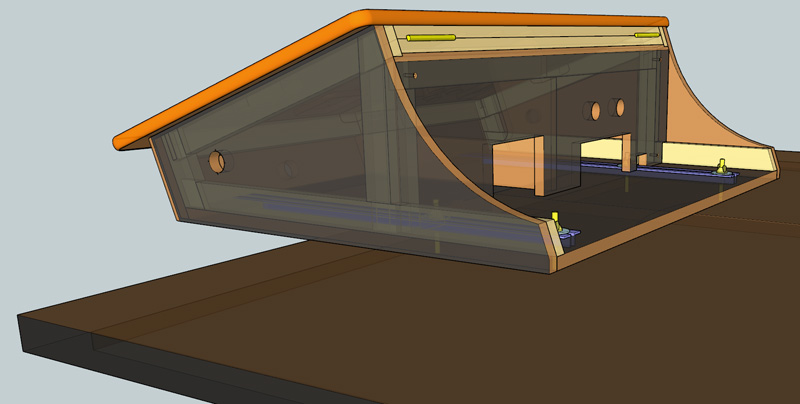

The top panel is hinged at the back like this:

Those chocks under the lid are to hold it in place when closed and take pressure off the hinges, as the top panel will likely be subjected to some shearing force in all directions.

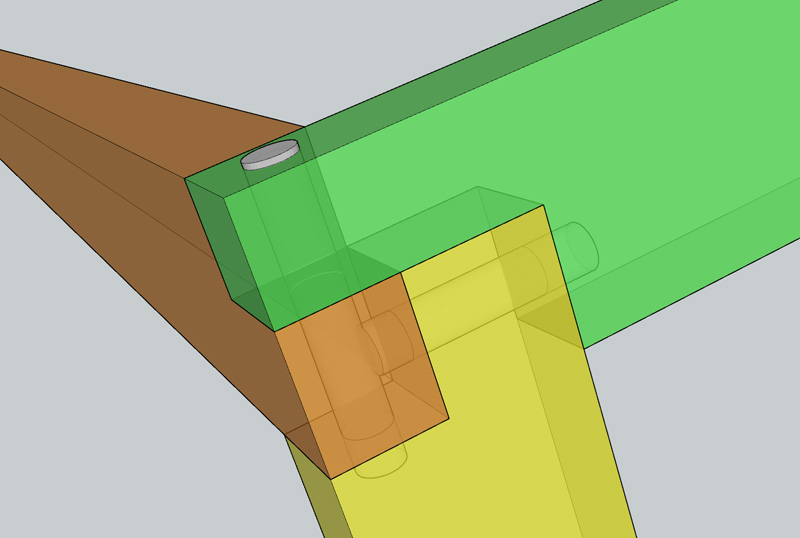

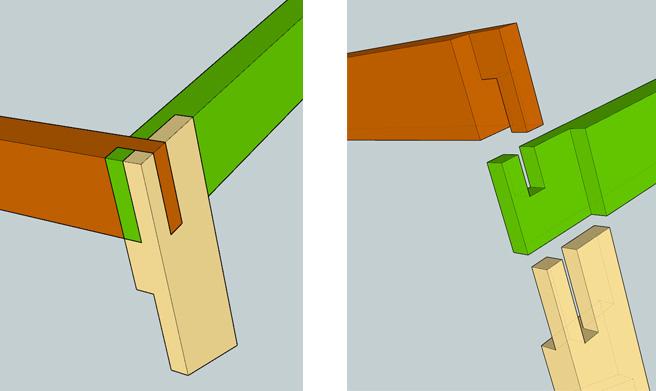

My biggest concern is the corner joins. First, the top front corners. I couldn't find any examples of 3 way joins using non square beams, especially ones that can take outward force rather than weight from the top. The first version I came up with was this.

I don't really have the confidence or time to make proper mortise & tenon joins, and have doubts about the strength of 1/3 the width of 19mm pine. Time and simplicity are an issue because I only have a couple days access to decent tools (I'm in Sydney, my friend's table saw is in Newcastle, I have less than 2 days to put it together.) With all that said, it was suggested that the above join would not be very strong, so here is another version, which is some odd combination of lap and notch joins.

Would this be better? Should I do something else entirely? Priorities are strength first, then ease of construction; appearance doesn't matter.

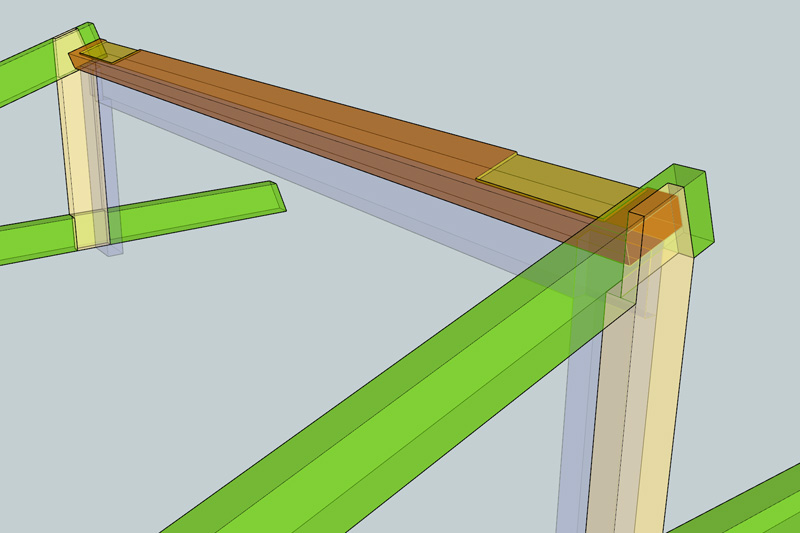

Lastly, the back corners. These are a bit of a mess.

The sides have an angled middle lap, but the crossbeam which takes all the weight when the lid is up is just butted against the sides. I figured two bits of dowel or screws or something should hold it up. But then I thought that was a bit too flimsy, so the transparent blue supports were added as an afterthought, but again they're just butted and screwed - plus that will give me something to screw the removable back panel to.

There's a lot going on here that is potentially wrong.. apart from it being a 3 way join at an odd angle, the crossbeam (orange) is horizontal and on lower half, that's bad, right? But it has to be that way because the top side is the lid half of the hinge, so that under the lid is flush with the the sides when it's closed. Any advice here would be really appreciated, maybe it's OK as is, or maybe it needs to be completely redesigned? I don't know.

One last question. I was thinking maybe ply or some other kind of wood would be better than MDF for the panels, but I don't know. Can you smoothly round the edges off marine ply, or will it show layers of grain? We're going to paint or maybe use adhesive vinyl around the sides.

Anyway, that's where I'm at. Thanks for taking the time to read, and thanks in advance if you have any advice or suggestions.

-

22nd January 2011 05:10 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

23rd January 2011, 12:49 AM #2

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

Personally, I'd go for 17 or 19mm plywood, it takes screws well and is almost as stable as MDF but rounding over may be an issue with exposing the grain. MDF will take screws fine, but it has to be pre-bored or it'll split.

-

23rd January 2011, 02:01 AM #3

It's way, way, waaaay over-engineered.

Which is not uncommon in arcade cabinet builds (I saw one in Atomic magazine that had a welded steel frame underneath a 20mm(?) MDF shell...oh, how I laughed...)

Use 16mm MDF, and ditch the internal frame.

Pre-drill the screw holes in the MDF to prevent splitting, or just hold it together with glue (PVA is fine) if you have some clamps (or even a brad nail gun) to hold it while the glue dries. (A light sand with 80 grit paper on the face of MDF helps the glue get in). The glue approach also means there are less holes to fill in if you want a smooth look.

The weakest point will be where the hinges attach. I'd just use a piano hinge (a continuous hinge, usually available in meter lengths or on a roll - cut to length with a hacksaw/dremel).

I noticed today that my local Bunnies had black faced melamine board - that could be an alternative material. It's a chipboard substrate, but you could cover the edges in PVC edge strip to hide it. Or use something like a jarrah veneer board and use brass screws and accents for a steampunk feel. Mr Ply and Wood should have a reasonable selection of boards on hand if you like an exotic veneer look.

If you use ply, it'll be lighter, but you'll have a lot more work to do if you don't want a natural wood look.

In any case, you can use marine epoxy adhesive (no, that's not araldite) to reinforce screw holes if you are worried about splits*. But with 16mm MDF, as long as you stay with 8 gauge screws and pre-drill (3mm drill bit from memory), you'll be pretty much right.

*How strong is epoxy? Read the 'Testing bolts in concrete' article. TL;DR version...metal eyebolt failed at just under a tonne, chain failed at a tonne, test abandoned at two tonne due to safety concerns for equipment. No epoxy failure.

-

25th January 2011, 05:16 AM #4

New Member

New Member

- Join Date

- Jan 2011

- Location

- Sydney

- Posts

- 7

Thanks for the replies!

Master Splinter, if you thought that welded steel frame was funny, you'll get a kick out of this... I built a smaller, single player one of these some 20 years ago, except the whole thing was made out of 3mm plate steel, and it was made from just one piece that was bent into shape, fixed onto a huge solid oak desk with 4 bolts. Still going strong after 20 years.

I'll definitely use a piano hinge, great idea, and have taken your other tips on glue and screw gauge on board, but as for ditching the structure... I'll be rounding off the edges and corners, and don't want screws visible from outside, plus this thing is likely to be subjected to a hell of a lot of abuse over many years. I really can't make it too durable or too heavy.

Had some good news, a friend has a festool domino joiner which is going to simplify the framework greatly, no more crazy joinery!

Similar Threads

-

Beginner project

By Johncs in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 11Last Post: 2nd November 2008, 09:18 PM -

Questions about french polishing [from beginner]

By Pavel in forum FINISHINGReplies: 6Last Post: 23rd June 2005, 08:43 AM -

Very addictive arcade game

By ozwinner in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 0Last Post: 12th April 2004, 06:06 PM -

beginner question: Adding finishing touches to a project

By samfpj in forum WOODWORK - GENERALReplies: 8Last Post: 14th January 2004, 10:39 AM

Reply With Quote

Reply With Quote