Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 26

Thread: Best Choice For Veneer Core?

-

10th June 2007, 08:46 PM #1

Best Choice For Veneer Core?

Best Choice For Veneer Core?

I need to veneer some thick (25mm odd) Silver Wattle to a core in order to make a panel approximately 60mm thick.

The panel will require a 45 deg join to another panel, which I was planning to use biscuits for. As you can see from the image the joint will require some strength, but the aim is to have the cantilevered panel forces transfered through the steel mesh to the panel below and so on.

What is the best material for the core, given that biscuits are going to be used? After checking my supplier yesterday I have the following options:

Material - Available thickness

MDF - 31mm

Ply - 19mm or 25mm

Particle / Chipboard - 25mmNow proudly sponsored by Binford Tools. Be sure to check out the Binford 6100 - available now at any good tool retailer.

-

10th June 2007 08:46 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

10th June 2007, 08:57 PM #2

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Nambour Qld

- Age

- 88

- Posts

- 688

Solid wood on an engineered board. How are you going to allow for expansion of the wood?

As I see it, you would have to laminate to a timber with similar expansion percentage, or use real veneer (less than 2mm).Brian

-

12th June 2007, 09:40 PM #3

-

12th June 2007, 09:49 PM #4

Hi Stink, so you are planning to resaw the wattle to 2mm and veneer both sides of the core? Then mitre it all and join together with biscuits for reinforcement?

Some dimensions of the unit will also help.I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

12th June 2007, 09:56 PM #5

Yep that's what I was planning. The thickness of the veneer is the only unknown. I was planning on using the silver wattle at 20mm top and bottom, but perhaps I could get it down to 5mm veneer over 2x 25mm ply core.

Only concern with thin veneer is keeping everything flat. I assume that I will need to dress both sides of the board, cut a veneer, redress the board again and then veneer again.

That way all cut veneers will have a flat face and then when they have all been cut I will then run them all through the thicknesser to make them all exactly the same thickness.

Only concern is the minimum thickness I can put through the thicknesser (I dont have one but have access to a big fella through the WW club).Now proudly sponsored by Binford Tools. Be sure to check out the Binford 6100 - available now at any good tool retailer.

-

12th June 2007, 10:13 PM #6

How wide/deep are the shelves, and do you need to edge join 2 pieces to make up the width?

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

12th June 2007, 10:23 PM #7

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Nambour Qld

- Age

- 88

- Posts

- 688

-

12th June 2007, 10:23 PM #8

Yes I will. Shelves are approximately 1300 x 350 and the wattle 3000 x 150mm.

Now proudly sponsored by Binford Tools. Be sure to check out the Binford 6100 - available now at any good tool retailer.

-

12th June 2007, 10:28 PM #9

Thanks Brian .... I guess that answers the question. I might have to rethink the plans.

Now proudly sponsored by Binford Tools. Be sure to check out the Binford 6100 - available now at any good tool retailer.

-

12th June 2007, 10:37 PM #10

Its not a basic task what you attempting to do, but also not too hard if you know what to do.

If you wanted that neat architectural look with flowing grain etc, you would need to do a fair bit of mitreing.....like on every edge. Not impossible by any means.

It would be a cinch if you used 0.6mm veneer with a vac press or used 19mm MDF veneer board which you can just form (cutting mitres) around a pre-made carcase.

Let me know if you want me to draw what I mean......

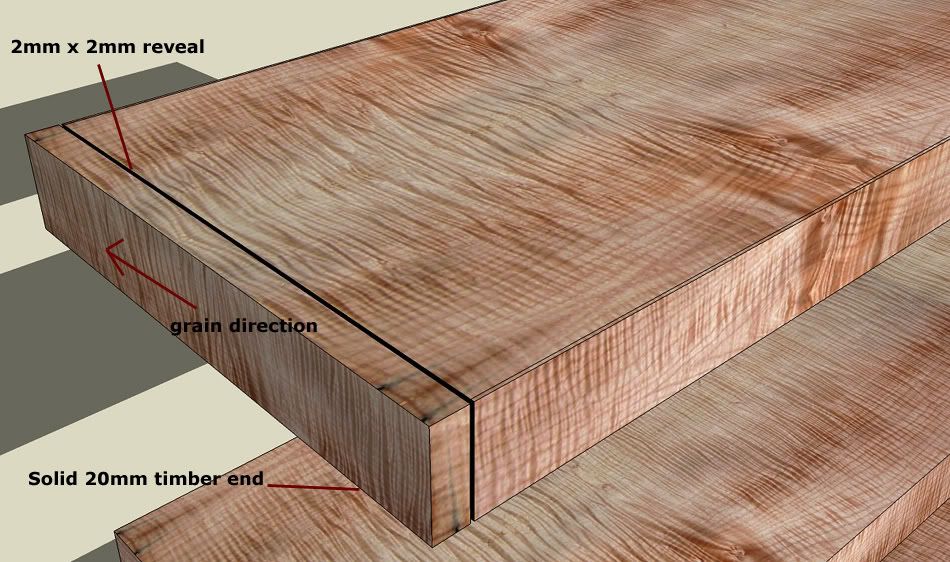

Below is a pic of 2mm veneer with 2/25mm mdf +1/6mm mdf for the core.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

-

14th June 2007, 12:45 AM #11

Novice

Novice

- Join Date

- May 2007

- Location

- Gippsland, Victoria

- Posts

- 21

How about common old kiln dried pine? Not much lateral strength but a cheap and stable timber.

Kauri pine was used as a laminate core many years ago - when it was cheap! Very stable and light with reasonable strength and has excellent qualities for machining.

Biscuits and chipboard do not got well together. Chipboard has very low gripping strength to hold biscuit and with easily rupture if stressed.

-

14th June 2007, 11:15 PM #12

Thanks for all of the replies guys ....

Martrix I know exactly what you mean. I don't think I have the skills to do a 2mm veneer and then make all of the mitres to get a perfect match. Each veneer panel would require an exact mitre of four sides in order to get it to fit together.

A 0.6mm veneer would be ideal, would it be possible to do this without the vac press? Doesn't leave much to play with. The veneered board is out as I have the wattle already and I would like to use it up.

As a fellow BP16a'er are you able to cut 0.6mm veneer acurately?

My initial ideal was to use a covering panel on the fronts and the ends, but I do like the idea of having the grain run to the end which will only be acheived by the 0.6mm veneer or the mitres as suggested.

Junction Box ..... as the corner joints will be mitred and joined with biscuits am I better off with ply or mdf?

I might have a play on the weekend and see what I can come up with.Now proudly sponsored by Binford Tools. Be sure to check out the Binford 6100 - available now at any good tool retailer.

-

15th June 2007, 12:40 AM #13

Stinky, have you thought about building a set of L-shaped torsion boxes?

They would be a very much lighter than solid ply or MDF

One jig should allow you to build multiple identical L shaped boxes.

The inside corner of the L would be solid timber and you'd "wrap" the veneer around the outside edge.

The ends of each leg would also be solid and could be mitred for joining. The underside of this joint would mostly be out of sight.

Don't forget you'll want some stock about 5mm thick cut off the edge of your silver wattle so that the grain runs the "right" way on the edges.

ian

-

15th June 2007, 09:03 PM #14

Novice

Novice

- Join Date

- May 2007

- Location

- Gippsland, Victoria

- Posts

- 21

Using biscuits in mdf or chipboard concerns me on a design like this because of the torque stress on the joints, even though you plan to use the mesh to provide support. From my experience mdf has a low grip strength so it may have some issues holding the biscuits. Ply should be ok.

-

15th June 2007, 11:12 PM #15

Hi, I wouldnt try to cut 0.6mm veneer on any Bandsaw. The type I was suggesting is sliced by a big guillotine. You will be able to cut 2.5mm veneers no problems.

Ply would be best, but I would have no problem with using an MDF core as long as those steel inserts are load bearing. I assume it is a wine rack?

Below is another possible way of doing it.

The method would be that you veneer both sides of the core but only half the overall width (1/150mm board at a time.) Once both pieces are veneered, you then join them together (long edge) like you would if they were solid 150mm x 60mm thick wattle boards to get the full shelf width. You could do it all at once, but I wouldnt unless you have a good Vacuum press setup.

Then you can cut the mitres on the shelves and join them together.

Lastly you cut/mitre and glue on the face veneers and the solid timber end pieces. The face veneers could probably be cut at around 1.5mm because they would only be 60mm high and would be easy to cut. Once glued on and sanded down, they would finish up about 1mm thick which you would barely notice once the sharp edges are removed. Come to think of it, you could also do the same to the end pieces instead of the 20mm thick solid timber.....worth a thought.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones.

Albert Einstein

Similar Threads

-

Stave core construction...

By AlanS in forum WOODWORK - GENERALReplies: 6Last Post: 25th August 2005, 08:24 PM -

laminating MDF glue choice?

By Gaza in forum GLUEReplies: 6Last Post: 17th June 2005, 12:34 AM -

Advice on drum sander / sharpener choice

By tonyhart in forum HAND TOOLS - POWEREDReplies: 8Last Post: 29th January 2005, 07:10 PM -

Advice to help in making a choice of purchase

By Mike_R in forum SCROLLERS FORUMReplies: 14Last Post: 25th January 2003, 02:02 AM

Reply With Quote

Reply With Quote

.

.