Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 9 of 9

-

3rd February 2007, 06:04 PM #1

New Member

New Member

- Join Date

- Feb 2007

- Location

- EastLake,Ohio

- Posts

- 7

Wanting to make a small garage cabinet?

Wanting to make a small garage cabinet?

Well first off im new here,so Hello!

Im just getting into woodworking,I know nothing about it so bare with me.

I just bought a table saw,and a router with table,and been wanting to make a small cabinet to mount on the wall. The measurments are roughly going to be 35"L , 26"H, 15"D.

First off what kind of wood do I use? I went to lowes today and was going to use some pine board,But all they had was planks. They had 12" planks which is to narow,then they had 16" that is ok,,but I would have to piece it together for the front and back seeing how the back should measure 35"x 26" if it were one peice.

I planed on doing the front that same way 35x26,and routering a fancy edge around,with a door having the same routered edge. But I cant find any sheets of wood,the only thign I seen was ply-wood,and as I found out routering ply-wood doesnt really work that well. Or some thick heavy partical wood "not sure what it was called,its not particalboard,it was smooth and solid" But I also wanted to stain the wood a nice color,and it didnt look like you could stain this type of board,only paint it.

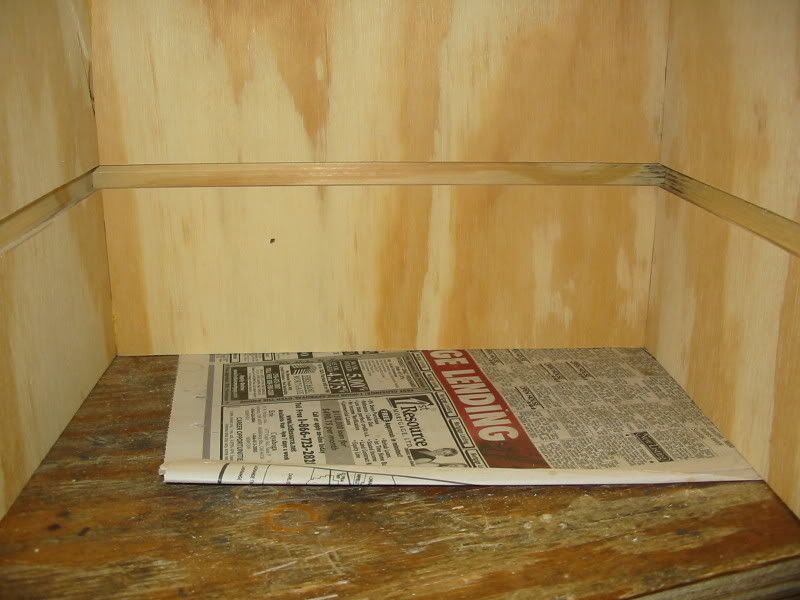

I was just out there messing around practicing on my cuts,and this is how I planed on building it "you have to imagine the rest "

"

I made a dado cut to hold the shelf .

Slipped in the shelf.

Now this is where you have to imagine the rest. There will be a top and bottom,and the front will be all one peice with 2 square holes cut out,leaving a litle lip inside the cabinet with routered edges,then 2 swinging doors.

Now this is where you have to imagine the rest. There will be a top and bottom,and the front will be all one peice with 2 square holes cut out,leaving a litle lip inside the cabinet with routered edges,then 2 swinging doors.

So thats my plan,Please tell me what you think,Like I said I never done this before so any help or advice will be appreciated.

-

3rd February 2007 06:04 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

4th February 2007, 12:54 AM #2

Hi there POD, and welcome.

The designs for cabinets, furniture, and almost everything else that you normally see have evolved over many generations to be good practical reliable ways of doing things.That doesn't mean that its the best way, but that it is a good basis to start from maybe. Your ideas for the garage cabinet are sound engineering in themselves, but you need to ask a couple of basic questions.

How big a load should the cabinet be able to support (including its own weight)?

Will it be basically "held up" from below, or "hung down" from the top?

Whichever way, the support (strength) needs to carry through to the shelves (in this case, shelf and bottom) from the point of support on the wall.

In a classical cabinet, the back wall may be non-existant, or only thin and weak, as there will be a strong hanging-rail across the full width at or near the top. That rail is STRONGLY connected to the end walls or (more usually) wall frames that carry the shelf. The whole frames thing is to lower the weight while keeping the strength.

The front of a cabinet is usually also a frame which gives the doors something to be hinged to, and close onto (like a square "8" on its side).

In your case, the strong ply sides might be a good idea, as you can obviously do a great job of dados and fitting a shelf to them, and that would be real solid. The floor of the cabinet might be best made 1" up from the bottom of the sides to give it the same strength. That leaves the question of the back, top, and front.

Adding a solid back is (I think) overkill, but if the wall you are hanging it on is solid enough to carry the whole shooting match (including when it's full of heavy stuff), then go ahead. One of your boards 6" wide across the back at the top would be enough to carry the whole thing, assuming it has no knots in it that might weaken it. If you did it this way, you have the option of not putting a back in it at all. If you need a back, a light 3-ply sheet will do. The fixing of whatever you use will have to be strong enough to carry all the weight...pre-drilled multiple screws of at least 3 inches long would be my choice.

Now, doors. Again, the frame thing is normal, especially so you don't get a big weight dragging down at the front when both doors are open, and their weight so far away from the wall, pulling OUT and DOWN on the whole cabinet. I'd say you shouldn't use solid doors for this reason alone. How you go about making lighter panelled doors I'll leave up to other information sources. Gotta go now, it's 1 am in this part of the world.

Bill

-

4th February 2007, 01:13 AM #3

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,796

And a big welcome from me POD.

Before we can really provide any significant help we need to know what you plan to put in the cabinet. So far you seem to be answering your own questions anyway so I's say carry on.

The thick ply look is fine and you can finish off the edges nicely with a beading of similar or contratasting wood, sand stain and seal - should look sweet.

cheers

-

5th February 2007, 04:07 AM #4

New Member

New Member

- Join Date

- Feb 2007

- Location

- EastLake,Ohio

- Posts

- 7

Thanks guys,

Well as what I plan to put in the shelf,nothing much,Just like car wax,spray paint,motor oil, cleaners,stain,maybe a few boxes of nails etc. Just small stuff that I have scatered on my work bench now.It not gonna be used for heavy tools or anything.

The wall that it will be mounted to is a cinderblock wall,I was going to use some plastic wall anchors and just screw it in through the back of the cabinet,sound good?

Also I used a 18guage brad nailer,and wood glue to keep it together,will this work?

-

6th February 2007, 07:33 AM #5

New Member

New Member

- Join Date

- Feb 2007

- Location

- EastLake,Ohio

- Posts

- 7

Anyone have any comments,on the nailer and glue?

Also I was at my wood store and was set on getting some plywood,and I seen half sheets of birch wood,,it looked like plywood to me,but it was much straiter and smoother.

Can anyone tell me the difference between the two?

Sorry if these are silly questions,but like I say im new to all of this.

Thanks

-

6th February 2007, 09:33 AM #6

Hi P.O.D.

The nailer and glue should be fine, imho.

As for the birch, I can't really say, sorry.

Any more photos coming? your work looks neat, tidy and suits your purpose perfectly.

Cheers

Wendy Box Challenge 2011 - Check out the amazing Boxes!

Box Challenge 2011 - Check out the amazing Boxes!

Twist One - Wooden Hinge/Latch/Catch/Handle

Twist Two - Found Object

Twist Three - Anything Goes

-

6th February 2007, 09:41 AM #7

-

6th February 2007, 10:15 AM #8

POD,

For $6, you can get these plans. I built this unit years ago with less equipment than you have now. The instructions are clear, the design is solid and well thought out, and you can modify it to your heart's desire. It's also a great way to practice on various joints and techniques.

It is mounted with a french cleat (details in the plans I think) and has been in good use for six years or so.

Many of these kinds of plans have good info on techniques as well as sizing and material lists, and I found them a great and inexpensive way to improve my skills as well as get something useful in the end.

Tex

-

11th February 2007, 12:37 AM #9

anyone having reservations about rawlplugs in cinder blocks?

POD, I'd look at the advertised holding power of the plugs, and try to work out how many you'd need...it may be more than just 2 or 3.

Cheers,

BillChipslinger

Similar Threads

-

Sure is quiet. How about some small tools to look at?

By Schtoo in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 13Last Post: 19th July 2005, 02:21 AM -

Anyone recommend a small, accurate table saw?

By tashammer in forum TABLE SAWS & COMBINATIONSReplies: 0Last Post: 22nd May 2005, 01:12 AM -

What do you make with your TRITON

By mim in forum TRITON / GMCReplies: 8Last Post: 10th January 2005, 08:06 AM -

Cabinet Design Software (Discounted)

By RubiconCabinets in forum ANNOUNCEMENTSReplies: 4Last Post: 20th July 2004, 06:30 PM -

Wanted, Someone to make 2 small wooden boxes

By warren in forum WOODWORK - GENERALReplies: 3Last Post: 30th July 1999, 08:49 AM

Reply With Quote

Reply With Quote