Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 19

-

15th September 2014, 09:57 PM #1

Intermediate Member

Intermediate Member

- Join Date

- Oct 2007

- Location

- NSW - Coolah

- Posts

- 34

What Mortise and tenon for a bed?

What Mortise and tenon for a bed?

I'm just about to start on a single bed for my 2 y/o son. Young I know but hoping he'll have it for another 20 ish years, or when ever he can't "live" without a double

I've got a few designs in my head, all pretty traditional/conservative. I prefer simple, solid furniture that relies on a nice timber and oil finish for aesthetics. Whichever I go for it will have four sturdy posts (75-100mm square) and cross/long beams of about 50x200 with no tail board and a slatted head board. What I can't decide however is what style M&T to use to join the post and rails. On the last one I made for me and my wife I did a blind M&T with a 45* chamfer where the two rails met at each post. Then I pinned them with screws so I could knock them down. It works ok but I feel isn't ideal as there is a small amount of play now (7 years later and 3 house moves including from UK to aus).

Doing some search it seems wedge M&Ts are popular but this just looks too chunky and crude to me, I'd prefer something more classic with less protrusion. This is more suited to an outdoor table IMO.

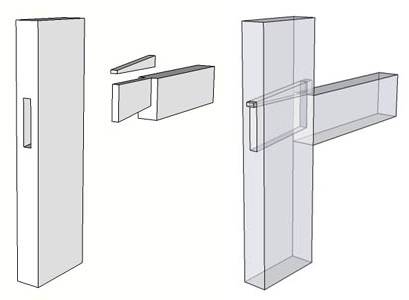

This is "dovetailed and wedged tenon" I like the look of a lot. I could cut the tenon flush with the post, and end of the wedge. It seems like it'd be pretty strong with the wedge driven in hard and could be adjusted if it loosens. Also looks fairly simple to make. Has anyone used one of these? In a bed? I just need to visualise how it would work with the cross beam and long beam crossing at the post, but I'm sure it can be made to work by staggering them...

Or has anyone got any suggestions for a different joint? Don't want to use any steel fastenings... Timber will probably be yellow box or a blue gum (not sure which, took it down a couple of years ago and milled it up then) as I have a fair bit around. All joints cut by hand

-

15th September 2014 09:57 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

16th September 2014, 12:13 PM #2

If it was me I would just go for the standard mortice and tenon joint in the construction of the header or foot. Then I will use the steel bed hardware for the longer pieces as this will be easier to disassemble if you have to move house.

One thing you could try to enhance the strength of the mortice and tenon joint is use Drawboring.

This is where a dowel is added to the joint and in the tenon the hole is slightly off center and when you drive the dowel in it bring the shoulder of the tenon hard up against the leg.

-

16th September 2014, 12:32 PM #3

I agree with the above. M&T the head and foot to the legs and use bed knockdown hardware to attach the side rails. It is a real bu&&er moving a bed in one piece. I used those below but there are plenty to be found online.

Keep posting as the project goes.

Regards

John

-

16th September 2014, 12:40 PM #4

I built my lathe bench using those wedged dovetail tenons. It's a good joint and you can tighten it up by tapping the wedge in harder.

You would attach the bottom rails at the bed and foot with mortices. I assume you'll use square legs, so there is plenty of room because you will have the side rails coming in closer to outside edge of the leg. Depends on the style of bed I suppose, but it's not unusual to have the bottom rails higher than the side rails to make access to the mattress easier for tucking in sheets."I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

16th September 2014, 06:53 PM #5

I used bed bolts through the post into the tenon/rail with my sons bed 3 years ago - solid as a rock, and easy to knock down....

edit - just noticed you don't want to use steel fasteners..... will leave my post for future searchers in any case....

bolts from here - http://www.horton-brasses.com/bedboltsbed.asp

Last edited by Astrodog; 16th September 2014 at 06:56 PM. Reason: hadn't read OP post fully!

-

16th September 2014, 09:34 PM #6

Novice

Novice

- Join Date

- Apr 2013

- Location

- melbourne

- Posts

- 19

A word of advice build a king single and not a single.

i built a single bed for my daughter 15 years ago which she loves but i wish i had of made a King single.

-

16th September 2014, 10:01 PM #7

Intermediate Member

Intermediate Member

- Join Date

- Oct 2007

- Location

- NSW - Coolah

- Posts

- 34

Thanks for the suggestions guys, although as Astrodog says I'd prefer to leave metal out of it. Yeah I'll be making it a king single for sure, might as well do it once. I wasn't fully thinking it through I guess - yeah I'll pin the cross beams to the legs no worries, and I guess it could even be a blind M&T rather than staggered. Yeah square legs. Not so sure about the bottom rails at a different height to the sides, reckon I'd prefer them the same. I'll put some photos up of our bed, it'll be a similar style

silentC that's what I wanted to hear - so far it's the joint that seems best. Just haven't seen it referred to for beds and not sure why

-

17th September 2014, 09:58 AM #8

Well it's a good joint to use in that situation. It has good shoulders to resist racking and being a dovetail, the more tension it is under, the stronger it will be. Plus you can knock it down by tapping the wedge out. It's easy to make, you just do it as for a through mortise and then use a chisel to make the sloping cut on the bottom side. Same with the tenon, just cut as for a normal tenon and then cut the bottom edge to match the mortise. After assembly, you can plane the end of the wedge flush so that it has no protrusions, or just leave it protruding by a few mm so you don't need to use a punch to knock it out.

"I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

17th September 2014, 11:17 AM #9

Intermediate Member

Intermediate Member

- Join Date

- Oct 2007

- Location

- NSW - Coolah

- Posts

- 34

Thanks sounds perfect!

Here's my last one, it's in a mess as I just took a quick snap. Can't find my build photos of it... Anyway next will be similar but haven't decided on the head board. Possibly the same but not sure on that, it wastes a fair bit of wood for the end posts. Although I won't do a footboard this time.

-

17th September 2014, 11:57 AM #10

Looks good. Nice and solid and I like the sleigh bed shape.

"I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

17th September 2014, 02:03 PM #11

Just a heads up for any other bed builders watching.

Was in Bunnings this morning and they had knock down bed brackets.

Regards

John

-

17th September 2014, 02:09 PM #12

Intermediate Member

Intermediate Member

- Join Date

- Oct 2007

- Location

- NSW - Coolah

- Posts

- 34

Thanks, yep it's pretty solid. Yeah pretty pleased with the design (although this part was my dad...), will get some better photos up later

-

17th September 2014, 02:49 PM #13

That's a real nice looking joint your thinking of using , Your going to mortise and tenon the head and end and glue them up, and these joints are for the long rails I take it ? As good as it looks I think they may want to loosen themselves a bit and that wedge may work free. You could draw bore a holding pin through as well,[ even put two in ] if the joint compresses it may mean making another wedge , but if you do its compressing when its assembled then fit the holding pin it may do the job well.

The Old Victorian four posters used to use Two bolts and two captive nuts in the rail,they were good . apart from them I've never liked the metal fittings , if just screwed in I think most fail with time, some I saw once looked OK . Thanks for putting in that Bunnings have them John , I will keep an eye out for them. I mightn't like most of them it it's worth checking them out.

Rob

-

17th September 2014, 03:50 PM #14

I can see where you are coming from, but the idea of this joint is that it can be tightened up if shrinkage occurs. If you pin it, then you lose that ability when it becomes loose down the track.

If you look at how the joint works, tension on the joint forces the edge of the dovetail into the wall of the mortice. The harder you pull on it, the tighter it gets.

For what it is worth, I made my lathe bench back in 2003 and it is still as solid as a rock."I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

17th September 2014, 08:08 PM #15

If you have plenty of wood to choose from get some 1/4 sawn for those long rails as well and if its dry enough shrinkage will be minimal .

Im not saying glue the pin in . you can tap the pin out and drive it in further , elongate the hole in the wedge. I just think in a bed that wedge may want to come out . If its just every once in a while it doesn't need it . it's an option though. out of all the things made and tenoned I thing the bed cops the worst punishment at that joined area.

I wedge some of my tables in various ways and sometimes they loosen up and I just drive them back in.

Similar Threads

-

Choosing a Type of Tenon for a Mortise and Tenon Joint

By Russell Cook in forum WOODWORK - GENERALReplies: 6Last Post: 13th December 2013, 10:21 PM -

mortise and tenon

By aus_07 in forum WOODWORK - GENERALReplies: 10Last Post: 26th September 2011, 06:38 PM -

Mortise and tenon in SketchUp

By brandy20 in forum DESIGN & DESIGNING / GOOGLE SKETCHUPReplies: 2Last Post: 1st February 2011, 12:30 AM -

Mortise & tenon vs half lap

By gonty in forum WOODWORK - GENERALReplies: 4Last Post: 6th June 2009, 10:50 AM -

Mortise & Tenon Jig

By John Saxton in forum WOODWORK - GENERALReplies: 20Last Post: 29th November 2003, 10:28 AM

Likes:

Likes:

Reply With Quote

Reply With Quote