Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 7 of 7

-

24th August 2013, 04:59 PM #1

Sawn Veneer, something interesting I saw today.

Sawn Veneer, something interesting I saw today.

I am doing a little bit of restoration work at the moment on a nice William IV Mahogany Teapoy . the area where the hinge screws in is in a mess and had been previously repaired with Hide glue , all the joins were a bit gappy and the glue failed, it may have been repaired twice before it came to me .

Once I had taken out all the broken pieces , scraped off the old glue and reglued them back into position again with a two pack glue I decided to cover the lost veneers on the back using a piece from my stash which is a nice old piece of Cuban sawn veneer taken from a lost back from a sideboard. It's 1.1 thick and I could see the saw marks on the back of the sheet ,where it had previously been glued to it's ground , I think ground is the right name for it ? It possibly fell of because those saw marks were left there , it did not have to be taken off with the hot iron and water , the polish is still on the outside to show that. You can see the polished side of the veneer to the right of the teapoy on the table.

This is where it got more interesting .

All the saw marks have left an even circular pattern , to show that it looks to have been sawn on a large circular saw

Roughly from what I thought I knew , sawn veneer stopped about 1840 when slicing techniques took over. What I thought happened before that was that sawn veneers were either done by hand or on some sort of reciprocating frame saw,that was a straight cut, or if it was later possibly a band saw , if it was to be done on a circular cutting saw back then I would not have thought the diameter would have been Huge .

I have been playing with a circle calculator for another project, Circle Calculator and I though it would be interesting to figure out the diameter of the blade that cut my old veneer , I rubbed chalk on the veneer back to show it up better and measured a chord of 250 mm with a segment height of 4mm and typed that in to the calculator , I thought it looked like it must have been a big saw ,

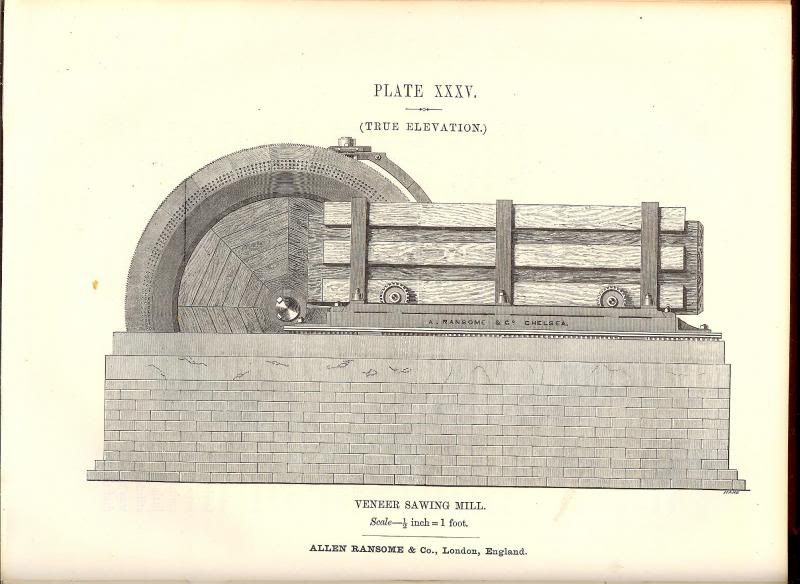

shewoops !! it said the saw had a radius of 1.95 meters , if I'm reading it right ? almost a 4 meter diameter blade . I was thinking a circular blade that big now maybe but especially back then, is that possible ? I did a bit of a search on the net and this came up . Out of a book by Charles Holtzapffel .

shewoops !! it said the saw had a radius of 1.95 meters , if I'm reading it right ? almost a 4 meter diameter blade . I was thinking a circular blade that big now maybe but especially back then, is that possible ? I did a bit of a search on the net and this came up . Out of a book by Charles Holtzapffel .

Sawing Ivory Veneers For Miniature Leaves. Part 2

That could be the saw that did the job !!

I'm always learning, cheers Rob

-

24th August 2013 04:59 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

24th August 2013, 05:19 PM #2

Rob,

VERY interesting.

What a lovely little piece of furniture!

My first thought would have been a bow in the blade of a reciprocating saw.

If the blade is light weight, it could bow back a fair bit in the cut.

Can you see if the cut is on the concave or the convex side of the curve???

What do you think?

Regards,

Peter

-

24th August 2013, 05:41 PM #3

Yeah , a nice piece . interesting construction as well , the top and the body being done on a lathe .

Im sure it's a circular cut . With any sawing of veneers I do on the band saw , if the blade dulls a little and you push harder so the blade does bend back a touch , results in a big change in direction of the cut, which causes the veneer cutting to fail.

-

24th August 2013, 05:44 PM #4

Interesting indeed. I'll have a look in some of my old books. I've seen a circular saw blade that size for cutting stone, but don't know about wood.

Are the saw marks more or less perpendicular across the board, or are they at an angle?

Edit: OK, I can see they're pretty well at right angles.

-

24th August 2013, 10:19 PM #5

Rob,

It is credited that Engineer Marc isambard Brunel was one of the originators of the large segmented circular saw used for cutting veneers.

Later a Mr Alexander Craig in 1831 took out a patent for "certain improvements in machinery for cutting timber into veneers or other useful forms"

A circular saw is mentioned as one.

There is much reading on the subject in books such as ..

M. Powis Bale's book, Woodworking machinery, its Rise Progress and Construction, 1880.

J. Richard's book, A Treatise on the Construction and Operation of Woodworking Machines, 1872.

Melbourne Matty.

-

25th August 2013, 02:18 AM #6

Nice picture Matt !! You come up with some good stuff!

I went back into the link tonight and read more , there is a lot of information in there, the previous link was to the saw section, this link shows all the chapters of the book , it's huge . and covers so much of what gets talked about here. it must have been linked to this forum before today .

Turning And Mechanical Manipulation | Charles Holtzapffel

Like in your picture Matt ,it said they filled in the spokes with timber for safety reasons, The segmented saw was made from small to large sizes ,for all sorts of applications.

For veneers , it said it was made from 5 to 19 feet diameter. They could handle logs up to 24 ' long x 5.5' breadth.

The operator who had to make the first section of each sheet turn off onto the guide did it with a thin blunt chisel called a Spud !

And it goes on to describe how it was sharpened , and operated.

You can see on the sheet of my veneer that because a tooth or two were slightly out on the day that the sheet was cut, The 4 meter blade was doing one revolution for about 8mm of travel.

Rob

-

9th September 2013, 03:24 AM #7

Interesting ... your 'spud' vs a 'bark spudder'

Paul

Similar Threads

-

some 'Blackwood' sawn today

By MAPLEMAN in forum SMALL TIMBER MILLINGReplies: 9Last Post: 30th August 2012, 11:28 AM -

Quarter sawn?

By Grain Man in forum MUSICAL INSTRUMENTSReplies: 18Last Post: 21st January 2012, 05:10 AM -

Interesting. Veeery interesting...

By Schtoo in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 15Last Post: 8th March 2007, 12:07 AM -

Getting a Log Sawn into Boards

By RobertEddy in forum TIMBERReplies: 9Last Post: 30th January 2006, 11:06 AM -

Interesting comment I heard today at Timbercon

By Wild Dingo in forum WOODTURNING - GENERALReplies: 5Last Post: 11th July 2003, 01:00 AM

Likes:

Likes:

Reply With Quote

Reply With Quote