Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 10 of 10

Thread: Table wobbles - need advice

-

8th November 2010, 09:53 AM #1

New Member

New Member

- Join Date

- Nov 2010

- Location

- Brazil

- Posts

- 1

Table wobbles - need advice

Table wobbles - need advice

Hi folks,

It is my first time here and I hope I got this message in the right area of the forum. First, thanks for hosting this forum, this is great!

I need some help with a table/bar that I am building. Every once in a while I come up with a project and start building it. I am no expert on woodworking but I get by, specially when there is so much info out on the web and there are places like this to help each other.

About the bar, here is two pictures of it:

Attachment 152456 Attachment 152457

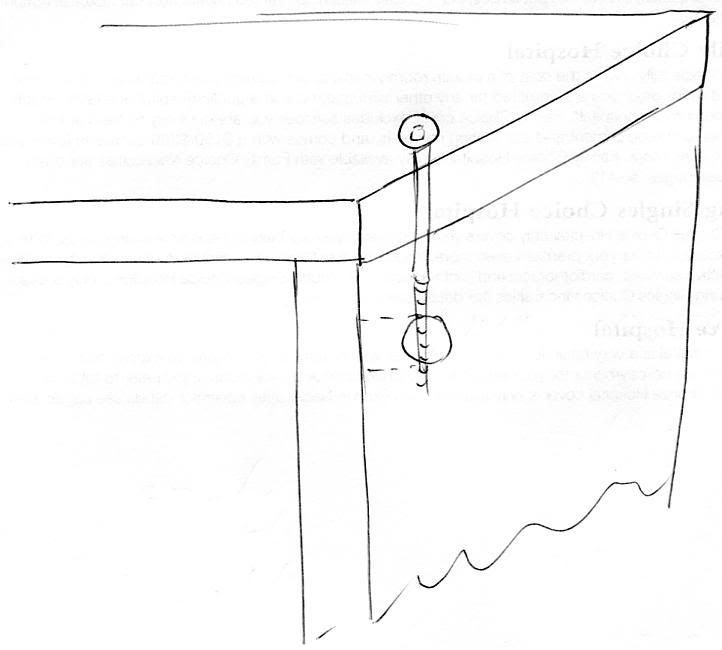

The problem is that it wobbles (no wonder why). It is basically 3 pieces of wood attached by pegs -- i didn't use glue because i would like to be able to take it apart once i move out and it is extremely heavy. The bamboo that is in between the two legs is not attached, but that is what i would like to do. There is a long and thick bamboo on the floor that I would like to run through the table legs through two holes and hold it with pegs (made of bamboo or wood) on each side of the leg (4 pegs totally)...

Before I start drilling holes I wanted to check with somebody more experienced. The wood was a bit expensive and I was hoping no to ruin it. I wouldn't like to have 2x4s running on the side either -- that i know would stop the wobbling but I was hoping to have something looking more natural with the bamboo.

Any advice guys? At this point a fly couldn't lean on the table because it is so unstable.

Uma

-

8th November 2010 09:53 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

8th November 2010, 09:45 PM #2

I know this might be obvious, but are you absolutely sure it is the table that wobbles and not the floor that isn't as level as it looks?

Cheers, Richard

"... work to a standard rather than a deadline ..." Ticky, forum member.

-

8th November 2010, 10:07 PM #3

Do you mean wobbling as in "it doesn't sit squarely on the floor"? Or do you mean the top is wobbling from side, with the sides leaning left and right like a wobbly cardboard box? (What we call "racking.")

Both problems are inherent in the design...

In the first case; f the floor's not flat it'll wobble. If any end of the side boards wasn't cut perfectly square, it'd wobble. if there's any twist to the upper board, it'd wobble. And putting feet on it would help rectify that problem.

But if you mean "racking" then the solution is bracing the diagonals. A backing sheet would fix it, but change the whole character of the piece. A subtler approach would be to string a pair of wires - or maybe bamboo - between the diagonals.

A less "in-your-face" compromise would be an apron running under the back edge of the top... although this would be less robust. Especially if only pegged.

(Just a few thoughts.)

- Andy Mc

-

8th November 2010, 10:12 PM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2004

- Location

- Melbourne

- Age

- 87

- Posts

- 1,327

I think Uma means it rocks . To overcome that I think you would need a more substantial joint connecting each leg to the top and glue it . Dovetails. Means you can't take it apart but what is more important , stability or demountability

I've just become an optimist . Iv'e made a 25 year plan -oopps I've had a few birthdays - better make that a 20 year plan

I've just become an optimist . Iv'e made a 25 year plan -oopps I've had a few birthdays - better make that a 20 year plan

-

10th November 2010, 09:28 AM #5

Given that you want to be able to take the table apart at any given time, the solution is not easy with that design. The answer, of course, is some form of bracing to counteract the racking which has already been suggested. Maybe you could do this incorporating some feature into the design such as a shaped board running the full length of the table and attached to the top and sides. This could be placed in the centre of the underside of the table and need only be quite slim but would provide a support to the top and sides. It could be attached with screws so it could be dismantled when need be.

Not an easy problem to solve but others may come up with some better suggestions.

Nice looking piece by the way. Reality is no background music.

Reality is no background music.

Cheers John

-

10th November 2010, 11:21 PM #6

Double sided tape it onto the floor and to a wall at the back. Then try not to use it.

-

10th November 2010, 11:24 PM #7

Sorry.

If you want you could get longer bamboo (or wood) and cut the ends into through tenons and have them running through the ends and over 30mm or so on each side and pin them, but you really need to have an apron also, at least a thin one 100mm deep at the back. It needs something keeping it square, or take it apart and dovetail the tops but you might still need an apron depending on how tight they are- if you plan on continually taking them apart they'll grow weaker..

Just realised everyone already gave a lot of this advice- Sorry everyone, didn't realise you already had the situation covered

Last edited by Eldanos of KDM; 10th November 2010 at 11:26 PM. Reason: Just looked at the other posts

-

10th November 2010, 11:37 PM #8

Uma

welcome

when you say It is basically 3 pieces of wood attached by pegs do you mean used dowels?

if so, the "problem" is your table has no portal rigidity where the legs meet the top

a better joint would be dovetails, but maybe not if you want to take it apart.

Knock down fittings will give some rigidity at the top-to-leg corners and would allow you to take it apart to move it, but a triangular reinforcing fillet would be better.

a pair of 100mm 90° shelf supports each end would also work, but be a bit crude IMO.

there are other options, such as angling the legs inwards somewhat so you taht the front elevation looks more like a trapesium than a rectangle would also work -- but would require a non-standard mitre angle at the top-to-leg joint which you might reinforce with a spline.

let's see what others suggestregards from Alberta, Canada

ian

-

14th November 2010, 05:23 PM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2004

- Location

- Melbourne

- Age

- 87

- Posts

- 1,327

Another option might be to make your own knockdown fittings using the countersunk 6mm hex driven screws used for treated pine use that are available from hardware stores .

glue a piece of say 1 inch dowell into the leg so that the screw has some cross grain to bite into .Use say 4 of these at each end . You should then be able to pull the leg nice and tight to the top and take it apart when you wantI've just become an optimist . Iv'e made a 25 year plan -oopps I've had a few birthdays - better make that a 20 year plan

-

14th November 2010, 09:56 PM #10

Member

Member

- Join Date

- Oct 2004

- Location

- Regional South Australia

- Posts

- 59

Genius..

Why didn't I think of this !!!..

..

..

I don't know if this would be in keeping with your design / Finished look..

But a modesty panel of the same width as the legs (Could also be narrower)

Fixed between the legs and to the top will deffinatly stop it wobbling !!!

Similar Threads

-

The wobbles

By Strine in forum BANDSAWSReplies: 6Last Post: 10th March 2009, 10:16 PM -

This mans answer to the Colly Wobbles

By Penpal in forum WOODTURNING - PEN TURNINGReplies: 6Last Post: 18th July 2008, 03:10 PM -

mc1100/900 head stock wobbles

By hughie in forum WOODTURNING - GENERALReplies: 5Last Post: 27th April 2006, 03:59 PM -

My Lath has developed the wobbles

By A-Marks in forum WOODTURNING - GENERALReplies: 9Last Post: 22nd March 2006, 07:15 AM

Reply With Quote

Reply With Quote