Needs Pictures: 0

Needs Pictures: 0

Results 16 to 30 of 47

-

19th March 2016, 10:36 AM #16

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2007

- Location

- Sydney

- Posts

- 749

Use Brent Beach Jigs!

Use Brent Beach Jigs!

This would be an ideal to use in conjunction with the Brent Beach design jigs - and would make a really inexpensive but highly flexible system for quick & repeatable sharpening.

(Note - I think that Brent is a bit obsessive with his tertiary micro bevels, but the jig system it really good & price is right.)

Use it with the Brent Beach "Stone Vice" system! These plates seem to be the ideal companion for this approach

Bu using shims under the cast iron plates, you could set this up so that the final water-stone used for polishing would be marginally lower when inserted, thus eliminating issues with registration that Brett has pointed out. This would mean the the water-stone would polish just a micro-bevel (all it really needs to do) and it wont matter it it wears a bit.

-

19th March 2016 10:36 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

19th March 2016, 11:06 AM #17

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,794

-

19th March 2016, 12:06 PM #18

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2014

- Location

- Caroline Springs, VIC

- Posts

- 1,645

Lol Bob, I just made that number up because I didn't want to go back and watch the video where Stuart from toolsfromjapan explains how to replace the diamond surface. But you made me watch it again. He said the tape is 0.12mm thick. My memory had me recalling a figure more like 0.012mm thick.

Fence, here are some pics of a titan chisel I just quickly flattened the back off using only the #140 atoma diamond plate. The first couple of pics are from when I held the chisel 45 degrees to the stone with cutting edge away from me. Ignore the bottom right corner of the chisel in the first pic, I haven't got it fully flat at the moment. The last few pics are when I turned the chisel 90degrees so the chisel is 45degrees to the stone with cutting edge towards me. You can see in the 3rd pic best where the left side of the chisel was not touched by the 2nd pass. This happens to all of the plate regardless of whether it is a 12mm chisel or a 2 3/8" plane iron. I get the same thing happening from plate to plate as well. By the time I hit the 12k shapton I can only polish the the center portion of the blade, but not any of the edges, they have all be rounded over much the same as sandpaper does. Does the same thing happen to you?

With that said, it is still shaving sharp by the end so it doesn't matter that much.

101_0244.jpg101_0245.jpg101_0246.jpg101_0247.jpg101_0248.jpg

-

19th March 2016, 12:19 PM #19

I've only done it laterally down the axis of the blade (sometimes I'll finish with a couple of sideways strokes to give some reference scratches to take out with the next grit. When flattening the 10" Narex paring chisels (which were bananas) there was no choice but to go down the blade axis.

I suspect that the leading edge will always get some extra taken off as the grit hits it. By making the cutting edge the leading edge for flattening it can at least be ground off when the sharpening is done.

-

19th March 2016, 01:02 PM #20

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,794

I looked into diamonds on CI a few years back when SWMBO got into lapidary work.

I found this 13 syringe piece set of diamond pastes (0.25 to 40 microns, something like 100,000 to 300 grit?) from THK Diamonds for US$22

They also have other syringe sets, and 20g jars of diamond paste are US$7.50

thk.hk

Has anyone tried these out?

-

19th March 2016, 01:40 PM #21

I've only used the Gemcuts paste (but does it come from China anyway???). The only thing I'd be wary of is the concentration of the diamonds in the paste, but they might be just fine.

Same place to get diamond lapping wheels from, but you already know that.

-

19th March 2016, 01:53 PM #22

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2007

- Location

- Victoria

- Posts

- 733

I have the thk syringes, bought from ebay years ago in a 10 piece set for about $20. Use it on the veritas plates. The labels fall off after a while so I recommend marking them with a texta.

Never tried another brand of paste but thk works well for me with baby oil as lubricant and as already mentioned its cheap and my plates appeared to have stayed flat. They do get scratched from thick wire edges though. LV recommends gluing their plates to thick plywood.

Guess an important variable is what your sharpening - O1 plane blades, LV yellow handled chisels and titan chisels at my place.

-

19th March 2016, 02:08 PM #23

-

19th March 2016, 04:01 PM #24

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2009

- Location

- Canberra

- Posts

- 1,301

Sam,

what does this mean: "They do get scratched from thick wire edges though." Where does the wire come into things?

Chris

-

19th March 2016, 04:34 PM #25

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2007

- Location

- Victoria

- Posts

- 733

Hi Chris,

the wire edge on the back of a blade after a coarse stone or grinding. Probably should remove it before hitting the plates but there you go. Not deep but marks them none the less.

FF - those devils wouldnt dare !! (As my eye twitchs at not being able to use my bevel up jointer plane on a shooting board)

-

19th March 2016, 07:36 PM #26

Hi all,

unfortunately I'm now out of cast iron. I will look for some more, but that is very unpredictable.

I've sent a PM to the last two requesters who will miss out for the moment.

In fact I had to scrounge a bit in my bins, but found some very old cast iron shelves out of a machine from 1922. Two people will get slightly different dimensioned plates: two plates are only 190mm long but a bit thicker, and two plates are only 70mm wide. All the rest are 75 x 200. If anyone who asked for two plates has a preference for thicker but shorter or 5mm narrower plates, just PM me so nobody gets an unexpected surprise...

Does anyone have any experience with the Carbatec Veritas mild steel honing plates? Here is the Veritas user guide. I can make some of those from anealed soft mild steel. They will be cheaper.I think. Haven't done the sums yet, but am thinking I can do them for between $25 and $30. I'll post about the final costs on the forum in the next few days.

I believe they will use a little more diamond paste due to the poorer embedding, but in terms of functionality and life span they should work the same as cast iron. But I don't know for sure.

Let me know if that is an option for any further requesters, otherwise you might have to wait for if and until I find more suitable cast iron.

All requested plates (up to last night) are now cut, ready for machining and grinding. I'm hoping to get them all finished and in the post over the next week.Cheers,

Joe

9"thicknesser/planer, 12" bench saw, 2Hp Dusty, 5/8" Drill press, 10" Makita drop saw, 2Hp Makita outer, the usual power tools and carpentry hand tools...

-

25th March 2016, 02:04 AM #27

OK, I found some more cast iron

it is only about 1/4" thick and I've found enough for another 8 plates or so. I'll continue to post progress here as I get things done.Cheers,

Joe

9"thicknesser/planer, 12" bench saw, 2Hp Dusty, 5/8" Drill press, 10" Makita drop saw, 2Hp Makita outer, the usual power tools and carpentry hand tools...

-

30th April 2016, 12:40 AM #28

I know this is dragging out a bit - and I'm sorry about that.

I'm slowly getting there though. I'm currently grinding about the first half of them - got a bit sick of running the shaper

In case you don't know that machine, it's function is a bit like a thicknesser, but with a single point tool that advances over the stationary workpiece, cutting off everything it touches - like bumps and high spots. The workpiece doesn't heat up in the process and therefore doesn't distort, like it can on a milling machine.

All the pieces are flattened now on one side and about half on both - they are the ones I'm grinding now.

When I have a batch done, I'll shape and grind the edges as well, so the pairs are the same length, width and parallel.

I'll post some photos of the process soon, when I've done the first handful.

I will then post them out in roughly the order they were requested, probably in small batches (post office is 15km from here).Cheers,

Joe

9"thicknesser/planer, 12" bench saw, 2Hp Dusty, 5/8" Drill press, 10" Makita drop saw, 2Hp Makita outer, the usual power tools and carpentry hand tools...

-

30th April 2016, 02:13 AM #29

Below is an old article that I once posted here (copied from my website) ...

Cast iron honing plates for diamond paste

Diamond paste is the current buzz, partly because it is cheap and partly because it cuts any steel and does so faster than anything else around. My own interest began when I needed to prepare chisels and plane blades from some of the supersteels, CP3V and CP10V, D2, and M2 and M4. My Pro Shaptons were not suited for these steels, and were better reserved for 01 and A2.

Diamond paste is available from many sources, such as the water-based pastes from Tools for Working Wood

and the mineral oil-based pastes from Lee Valley

Smear a pea-sized blob around your substratum, and use this as the honing medium. Substratums may be hardwood, MDF, mild steel but the best is cast iron.

The diamond bed themselves into the substratum, and then behave like a diamond plate. Recharge them ever now-and-then. The diamond paste in the above syringes should last a long time. I purchased a few tubes on Ebay some years ago, and it does not look like running out for some time yet.

Which grits? I am using three: 40 microns, 10 microns, and 0.5 microns.

I was looking around for a better substratum than hardwood, which I had used with moderate success for a few years, and really wanted cast iron plates. Buying suitable plates, which would need to be machined flat, appeared to be a costly option.

A few of us (Tom at Wood Central, one other) appear to have come up with the same idea at around the same time, so I cant take all the credit for this. The idea is to cannibalise old, broken cast iron handplanes for their soles.

The plates I made all run about 6 in length and a little over 2 in width as I used smaller planes. I freehand sharpen so this size is ample for my needs. This may not work well for those using honing guides in which case use larger plane bodies. If you do use a honing guide, I would recommend laying down a thin sheet of vinyl sheeting to safeguard the wheels and wheel bearings.

Building the honing plates

- I used a metal bandsaw to cut up the body, saving the area from the mouth to the rear.

- Build a simple box around the body.

- Once the glue has dried, raise the box on steel rules. This will enable the iron sole to drop through the bottom. The idea is to raise the cast iron plate a few mm above its wooden base.

- Now fill the interior of the base with car filler.

- Prepare a base/lid for the box.

.. and glue it on. Almost done.

- Add strips of 220 grit sandpaper for non-slip

- To run in the lapping plate, add a few peas of diamond paste, even it out across the plate, and then use a blade to press the paste into the surface of the iron.

In the picture below I have flattened an old Witherby chisel on 40 micron diamond paste.

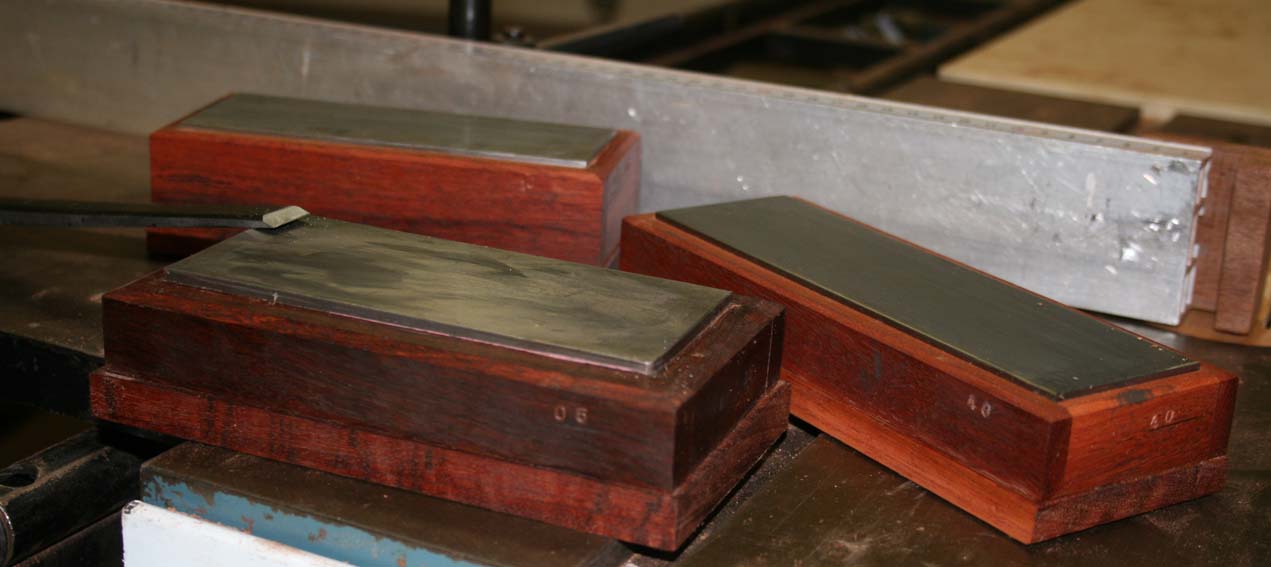

Below are three plates:

40 microns 7 ½ x 2 Ό (from a #5 Ό)

10 microns 6 x 2 Ό (from a #3)

0.5 microns 6 x 2 ½ (from a #4)

Note that all the plates are stamped with the micron number you do not want to contaminate a plate by adding the incorrect paste.

All the best with yours.

Regards from Perth

Derek

April 2011Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

30th April 2016, 11:11 AM #30

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2007

- Location

- Victoria

- Posts

- 733

If you have the tools, time and spare plane bases that's a good solution Derek. The LV plates are $40 at Carbatec otherwise which isnt too bad IMO.

Do you still use these plates or diamond paste ?

Similar Threads

-

Experiment with diamond paste honing

By Ben Dono in forum SHARPENINGReplies: 26Last Post: 25th March 2016, 11:27 AM -

Cast iron fireplace - Question for restoring using Penetrol & Liberon Iron Paste

By mookschank in forum METALWORK FORUMReplies: 8Last Post: 19th June 2013, 06:32 PM -

Cast iron for diamond paste plate

By derekcohen in forum SHARPENINGReplies: 13Last Post: 28th April 2011, 10:22 PM -

Diamond paste sharpening

By derekcohen in forum SHARPENINGReplies: 53Last Post: 8th April 2009, 02:50 PM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote