Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 5 of 5

-

27th March 2013, 02:34 PM #1

Router Plane Sharpening Jig (Hacked Attempt #1)

Router Plane Sharpening Jig (Hacked Attempt #1)

The time has come to remove the monstrous secondary bevels from my solid router plane blades.

I started doing it freehand last night and ended up badly mucking up one of them so I slapped this doohickey together today to help keep the bit square and flat to the sharpening surface.

It's just some rubbishy pine and MDF. I guesstimated the angle for the end of the pine which is what defines the bevel and there's a 90 degree V cut in the top (with the point cut out deeper) for the shaft of the blade to rest in. The MDF chunk rides under the sharpening plate (glass on MDF) and helps keep everything square.

It's rough as guts and not particularly easy to use but gets the job done. When I've had a bit more of a think about it I'd like to try and come up with something that's adjustable, holds the blade better, rides smoother and doesn't have the blade sliding horizontally over the grit...then have a crack at making it out of metal(s).

(BTW: In the background of the second pic you can see what happens when you spill turps on your favourite mouse mat )

)

-

27th March 2013 02:34 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

27th March 2013, 05:29 PM #2

Hi RSG

That is creative thinking, which I applaud ... but there is a better way.

To hone a router plane blade by hand is terribly easy and should take but a few seconds once the preparation work is done. This is what I do ...

The blades all come with a flat grind, and this is difficult to hone without rocking the face on a stone. That is where the frustration lies, and the upshot is a poorly sharpened bevel.

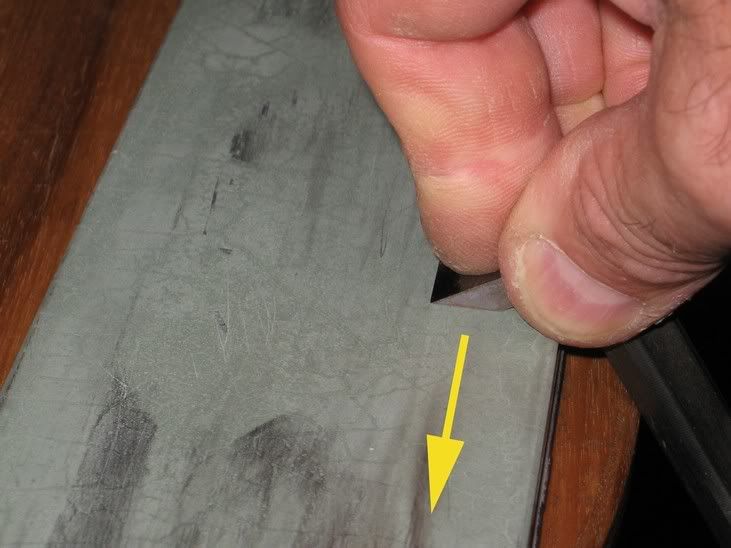

Here is a (LV) router plane with a sharpened bevel. Sharpened to a razor edge ...

What you should note is that it has a hollow grind. Freehanding a blade with a hollow grind is pretty easy. The hollow is the jig.

To achieve the hollow you can do the following:

1. If you have a LV blade with the removable 1/2" head, it can be attached to an extension and sharpened on a grinder, and even a honing guide, without much difficulty.

2. I use either a small grinding wheel on a drill press, or a hand grinder (such as a Dremel) to add a slight hollow to the bevel face.

The result may be subtle like this ..

However, it is sufficient to guide the face over waterstones in a secure manner ...

A pass or two along 1000/5000/8000 stones and you are done.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th March 2013, 07:52 PM #3

All that's much appreciated Derek. I didn't realise that it was a hollow grind

The two blades I use most are solid pieces and when I got them second-hand the bevels were a bit all over the place and looked like they'd once been a convex shape with only part of the leading edge flattened. I only sharpened the already huge secondary bevels just to get myself along but now it's time to do them properly.

Where I stuffed up last night was by completely freehanding (no tool rest) on the side of a grinder wheel (which was the start of the problem) before I went to the glass plate to get it flat (which exacerbated the tilted bevel). I wasn't paying enough attention to notice the shaft was sitting at when pressing on the bevel.

The jig will at least keep me off the grinder, which is pretty poor, and help get the bevel back to a proper horizontal level. Hopefully then I should be able to follow up with your advice and finish it off.

In hindsight it seems the jig is best used only to create a new bevel and give a flat reference point before continuing on with getting and edge and following the your method. I'll keep working with it tonight and see how I go, otherwise I'll see what sort grinding bits I can pick up for the drill press tomorrow.

Cheers again

-

28th March 2013, 07:59 PM #4

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jan 2004

- Location

- Bellingen

- Posts

- 587

Hey I like that jig! Well done!

They are tough little buggers to grind. I don't hollow grinding mine as I can't see how you could do it unless I'm missing the obvious!

I was a hollow grind everything guy untill about 15yrs ago I tried some tools that were not hollow. I have never looked back!

I think a hand router is one tool that would really benefit from hollow ground cutters. Having said that, you can still get the old ones to sing without it!

-

28th March 2013, 08:48 PM #5

I've changed my mind...the jig in it's current form is useless. It really needs to be able to move easier and hold the blade in firmly while at the same time pulling it back along the rest to keep pressure on the grit. Ultimately it's probably not even worth pursuing upgrades as what Derek suggested (and what I ended up doing) is far, far easier. Live and learn

After a quick look around today I couldn't find anything suitable for grinding in the drill press. In the end I kludged a fresh angle grinding disc to a headless bolt and freehanded a small reference face that was on the correct plane and at a comparatively shallow angle (guesstimated) so I could continue refining the reference and flattening out the rest of the mess on a coarse oil stone before I put it on glass and sand paper to finish off (got no waterstones atm).

Forming a new bevel like this is slow and a bit hard due to finger cramping but it's working quite well. Once the new bevel is done it will be a breeze to keep the blade sharp and in shape compared to before.

Similar Threads

-

sharpening plane blade

By Harrison in forum SHARPENINGReplies: 4Last Post: 3rd November 2009, 09:42 PM -

Sharpening router plane blades?

By wsal in forum SHARPENINGReplies: 2Last Post: 19th January 2009, 12:47 PM -

First attempt at restoring plane

By Alison556 in forum HAND TOOLS - UNPOWEREDReplies: 13Last Post: 22nd September 2008, 09:37 PM -

Sharpening Jig Plane blades

By Woody1 in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 18Last Post: 2nd November 2005, 03:38 PM -

We was hacked

By ubeaut in forum ANNOUNCEMENTSReplies: 31Last Post: 6th May 2005, 06:40 AM

Likes:

Likes:

Reply With Quote

Reply With Quote