Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 75 of 78

-

28th August 2012, 03:27 PM #61

-

28th August 2012 03:27 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

28th August 2012, 04:47 PM #62

-

29th August 2012, 02:32 PM #63

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2011

- Location

- McBride BC Canada

- Posts

- 3,543

I would expect the diamond paste to vary, depending on how it was made. Silly to imagine a uniform particle size, plain as that.

They can tell you some nominal particle size ( eg 0.25 micron). BUT, the difference will be the range of particle sizes in the goop. +/- 0.25 micron for one supplier, +/- 0.5 micron from another.

As a short note added in proof, I used diamond knives in a past life. $1,500.00/mm of edge. $1,500.00/mm of edge to get it sharpened. And you want to try to do what? with steel?

-

31st August 2012, 09:17 PM #64

I read something about average particle size in diamond paste recently ...

No idea now ... but the figure given is an average particle size and the discussion was relating to what the maximum size might be in different brands.

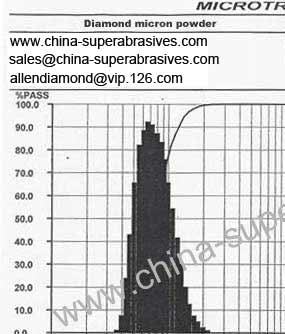

Here's one chart as an example: Diamond micron powder - 0-0.5 micron

And a fairly old spreadsheet that I might have already posted:

http://www.google.com.au/url?sa=t&rc...7gSqft9OwhfUFQ

-

31st August 2012, 11:33 PM #65

Intermediate Member

Intermediate Member

- Join Date

- May 2012

- Location

- Brisbane, Queensland

- Posts

- 44

OMH, what a great thread. But to take it back to something IanW said.

There is something being made. Some of the most beautiful shavings I have ever seen. I used my old trusty chinese cheapo plane for the first time in several years and got carried away making shavings. Been a long time.

Now off to learn more.

btw, omh is an Australian version of omg. Oh My Hat.

-

1st September 2012, 06:00 AM #66

-

4th September 2012, 10:37 AM #67

I initially thought that if I chipped in here I'd be the joker in the pack ... but I think I would more accurately be described as a Pokemon card.

Also I need to say Brett that it took me about a week before I had even read to the end of your initial posts, so damn fine job putting your thoughts together.

I haven't chipped into this thread in the sharpening section because I don't know that I can improve the discussion. In fact I'm pretty sure I could drag it down a notch or two In the two years or so that I have been accumulating old planes and trying to learn about them and sharpen and use them, I've only had a brief encounter with waterstones. I have seen them used by David Charlesworth, Chris Schwarz, the demo guy for LN, etc etc but I just got a gut feeling that I didn't connect philosophically with them when they are so prone to dishing.

In the two years or so that I have been accumulating old planes and trying to learn about them and sharpen and use them, I've only had a brief encounter with waterstones. I have seen them used by David Charlesworth, Chris Schwarz, the demo guy for LN, etc etc but I just got a gut feeling that I didn't connect philosophically with them when they are so prone to dishing.

Along with the old woodies that I started off buying I also bought some old carborundum oilstones as they came up - and most of my learning to sharpen up to this point has been with them. Recently I have found nicer old oilstones, but it wasn't that long - in the beginning - before I managed to sharpen a plane blade to some degree of sharpness and plane a 2"x2"x12" piece of jarrah smooth enough that I kept it by my laptop for the next week or three.

So I guess that feeling I could achieve what I felt I would want/need to in the future, I haven't investigated much beyond the simple stuff I have now.

Having said that, I have had a long-term objective of doing some carving 'one day', and been buying some carving tools over the last 6-8 months. Then at our wood show I met some people from the WA Carvers Guild, and have been going to the local group on monday morning now for a few weeks. I sat with my as-were carving tools over the course of a week or so at night getting them into a working condition - using my oilstones - and it worked out pretty well (for a beginner).

I should say that re plane blades I had 'tried' stropping with an old leather belt and not noticed any benefit, so I would now-a-days just 'strop' it on my palm like the older books say. It was at the carving group that I was introduced to the green CrO2 on the leather (which of course I had heard of) and I've been very impressed at the difference it makes in finishing and then freshening an edge.

The carving guys liked the old tools,and thought it very 'quaint' (they are pretty polite) that I would be sharpening with the oilstones. Although they liked the smell of the baby oil at least They basically use coarse, fine and extra-fine Dia-sharp diamond plates (used dry) - some of which the club have - plus stropping on leather or mdf or spinning shaped motorised mdf discs. I have used these yesterday to sharpen a couple of V-tools that I hadn't succeeded with before and I can see the attraction. But I still like the oilstones also.

They basically use coarse, fine and extra-fine Dia-sharp diamond plates (used dry) - some of which the club have - plus stropping on leather or mdf or spinning shaped motorised mdf discs. I have used these yesterday to sharpen a couple of V-tools that I hadn't succeeded with before and I can see the attraction. But I still like the oilstones also.

This started off being a reply back to Toby re the tools I was using on the Oregon workbench - which are in a normal sort of state for me in my development so far. My laptop wallpaper picture is of one of Ron Brese's planes with a thin full-width ribbon of shaving about 12" long or more that it has produced. I have never produced a (full width) shaving like that in my life, but I don't have any ambition to in particular. My guess is that I can get along to do what I want with roughly what I am doing now ... but time and more experience may make me eat those words.

Oops - I meant to say - seeing what the CrO2 could do for me (apparently about equivalent to 0.5 micron or a 8000 japanese stone) - I understand more about the discussion over diamond paste etc - but I think I'll just go with the crayon.

When it's written I'll put a link here to my (possibly horrifying) blades that I planned on talking about to Toby.

https://www.woodworkforums.com/f213/o...ml#post1546613

Thanks,

Paul

-

4th September 2012, 11:30 AM #68

Brett, I would debate that point now. A few years ago I would have said the same as you. Indeed, a recent discussion on this topic on WoodCentral has renewed my thinking on the matter.

A major user of monocrstaline diamond is DMT. I will not purchase any more of their plates. They simply do not last well (I must emphasise that this is sujective opinion supported a number of others whose opinion I value). As I understand, the shape of the monocrystaline edges are less multifaceted than the polycrystaline types of diamond, as used by Eze-lap. My DMT stones lasted about 18 months on average. My EZ is still going strong after 10 years. Others report the same. What we think is happening is that the polycrystals offer another sharp edge after the mono have been rounded off.

In paste there are two issues: the first is whether mono or poly is used. But probably the deciding factor is the concentration of the grit in the paste itself. This varies from one seller to another. Cheap is more likely to have a low concentration. You get what you pay for.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

5th September 2012, 10:21 PM #69

-

6th September 2012, 03:54 PM #70

Novice

Novice

- Join Date

- Dec 2009

- Location

- Canberra

- Posts

- 23

DMT stones

DMT stones

It's nice (well not really) to find someone else who has had problems with DMT stones - I'm still in shock from lightly dressing my Spyderco ceramic stones under running water, and then noticing a distinct lack of diamond in some areas on my DuoSharp extra coarse/coarse stone. The look and sound is now distinctly different in some areas.

I know dressing ceramic with diamond will wear the diamond, but it happened almost immediately.

People on razor sharpening forums talk of using diamond stone-flattened ceramic stones to whet cut-throat razors and I thought I would go down that path for a better edge on my plane blades.

I emailed DMT and to their great credit, they told me to send it back for assessment, but I haven't yet.

-

18th October 2012, 07:26 PM #71

Joel has had some further thoughts on grinding on his blog

-

18th October 2012, 10:37 PM #72

I have received some sintered diamond stones from japan and been experimenting with these and diamond paste. I can tell you I have some scary sharp blades. I started with the 600 then 1000 and on to the 6000 diamond stones. I finished with 8000 followed by 14000 diamond paste on MDF. I can say this method is not completly without mess but much more cleaner than using water stones. What I liked apart from their sharpness is I can see my face quite clearly almost like a mirror in the bevel edge and it took little effort. Now some of you will have seen these pics in the handtools unpowered sub forum but for the rest of you it is my new Veritas Block plane that I'm in love with at the moment. After receiving it I sharpened it with the process mentioned above and then gave it ago. The shaving if you look closely, you can see through it. I can attest it is still shaving very well after use over two weeks off and on. This may say something about Veritsa blades but I bet it has something also to do with the nice and scary sharp blade.

SBPower corrupts, absolute power means we can run a hell of alot of power tools

-

8th September 2014, 11:56 PM #73

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

A thread from the dead. I note that FF (Brett) recently posted about his dislike of water stones in another thread and for some reason I was reading this thread in which he made the same point two years ago. Elsewhere in this thread the point was made that sharpening is a journey in which we experiment and change our methods as we learn and I was wondering if Brett has made any radical changes. I guess I am going through the same thing now and am interested in the whole "journey" thing. Any thoughts form anyone else going through the same process of learning and the changes they have made over the years would be welcome also.

CHRIS

-

9th September 2014, 07:45 AM #74

Chris i still feel (and use) exactly the same about diamond paste on blocks. Reckon I can get the job finished before a waterstone has even been soaked long enough. As Superbunny points out, it is not entirely mess free with paste (you get a bit of black crap on your fingertips) but it's SO much easier to clean up than water everywhere, grit and slurry everywhere (and that is a big PITA). You can use a block for two different pastes, so the storage is halved, and the BIG thing for someone just coming in is that the start up costs are much much lower, as are the ongoing costs.

-

9th September 2014, 08:46 AM #75

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

I have changed from using paper to diamond plates to a Worksharp and diamond paste on MDF. I recently bought a lapping plate to see if it was any better than MDF with the paste but haven't used it yet. I am also going to get some diamond discs for the Worksharp to see how they go as all the reports I have read rate them very highly. I also recently gave in and ordered Stuart's recommended stone set from Japan Tools along with the Atoma diamond plate but they have only been used to sharpen a few knives so the jury is still out on these. I rate the Worksharp very highly to get the initial bulk of the work done but some have trouble doing the backs of chisels without leaving deep marks in them from the edge of the disc.

As for slow grinders there are a couple of options which I might try. Firstly a three phase grinder with a vfd would work and as I have three phase I don't have to change the motor configuration. The next is a belt driven grinding pedestal and change the pulley sizes but I suspect that the pulleys could not be changed enough to get the required speed so the VFD will get the nod there. Also a cheap wet grinder, toss the water bath and put a CBN wheel on it (Delbs did this??) but I always thought they would be too slow but would be happy to be proven wrong. I tossed one out some years ago as it was a useless piece of rubbish I had been given but now I see the possibilities, oh well such is life.

I can see how people constantly change because they have an interest in sharpening but all I want is a method that works quickly with no mucking around for me and beyond that the interest stops.CHRIS

Similar Threads

-

Simplicity Wooden Clock WIP

By two40 in forum CLOCKSReplies: 32Last Post: 11th July 2012, 01:11 PM -

Tricky situation - advise from wise heads

By Ringtail in forum FINISHINGReplies: 18Last Post: 5th April 2012, 08:47 AM -

Sharpening turning tools: some comments on Hock's new book

By rsser in forum WOODTURNING - GENERALReplies: 18Last Post: 29th January 2010, 12:35 PM -

Medical Breakthrough

By Barry Hicks in forum WOODIES JOKESReplies: 1Last Post: 5th May 2008, 08:56 PM -

Technological Breakthrough

By Baz in forum WOODIES JOKESReplies: 6Last Post: 14th September 2006, 10:32 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote