Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 51

Thread: Show off your sharpening tools

-

5th June 2007, 11:37 PM #1

Show off your sharpening tools

Show off your sharpening tools

It is time for another one.

There are mine. A Tormek, a couple of diamond plates, water stones and natural stones, diamond files and a Veritas sharpening jig.

Now I use the Tormek for most of the sharpening but I still use the Veritas jig for all my Veritas planes.

The Tormek costed me a little bit but it is great to be able to sharpen the jointer and thincknesser blades all the time.Visit my website at www.myFineWoodWork.com

-

5th June 2007 11:37 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

6th June 2007, 10:28 AM #2

We all love sharpening and we all have a set of sharpening tools. How many water stones do you have?

This is thread is about sharpening so I am expecting > 10 pages. Visit my website at www.myFineWoodWork.com

Visit my website at www.myFineWoodWork.com

-

6th June 2007, 10:38 AM #3

I've got three waterstones, some cheap diamond plates, three sharpening jigs, a bench grinder and a horizontal grinder I made.

I'm going to start one on drill bits

-

6th June 2007, 02:58 PM #4

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2004

- Location

- Sydney

- Posts

- 604

A bench grinder, a large sheet of thick glass and sheets of various grades of wet and dry papers. Oh and a can of spray glue to make it work.

Ross

-

6th June 2007, 03:45 PM #5

G'day

Grinder and makita wet sharpener

diamond plate, five waterstones

veritas honing jig, and one for japanese blades.

veritas scraper sharpening set

one of those long float glass thingies

honing compound, leather pad,mdf strip

angle gauge, and gauge for setting jointer blades

cheers

-

7th June 2007, 11:23 AM #6

Novice

Novice

- Join Date

- Nov 2005

- Location

- brisbane

- Posts

- 21

I brought a jig at the Bris ww show not cheap but best thing since sliced bread.

lets you sharpen tool upside down with tool fixed. You move diamond / stone / sandpaper etc. Even does scrub plane blade perfect.

Sharpening is now no longer a frustrating science every tool at right ( my right ) angle every time. Can just throw chisel on mid job with ease.

will take pics and post

rod

-

7th June 2007, 08:34 PM #7

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

Bin full of worn wet and dry doesn't make much of a pic.

For plane irons and chisels, what would be an economical step up from 'scary sharp'? Got a grinder for shaping, so a couple of waterstones?Cheers, Ern

-

7th June 2007, 09:26 PM #8

Senior Member

Senior Member

- Join Date

- Mar 2005

- Location

- Razorback

- Age

- 66

- Posts

- 194

3 sheets of glass and a heap of wet and dry - again not much to look at. Almost forgot, a hairless left forearm from checking how sharp my chisels are. If they don't shave they aint sharp enough.

-

7th June 2007, 09:35 PM #9

Three Shaptons (2K, 5K and 8K), three Kings (800, 1,200, 6K - only use the 1,200 occasionally since getting the Shaptons), Shapton's Kubo diamond reference lapping plate (awesome beast), Veritas Mk1 sharpening jig (no longer used), pump pressure container, and an old battered bucket. Also a Ryobi 8" grinder.

All my sharpening is done on the garage floor on two blocks of wood.

DesLast edited by Des.K.; 7th June 2007 at 09:38 PM. Reason: Forgot my grinder. (Sorry grinder)

-

7th June 2007, 10:04 PM #10

I have as follows

8"makita bench grinder with a carbatec angle plate

6" makita bench grinder

sheet of hardened glass (side window from a Toyota troopie)

lots of different grades of wet and dry paper and crocus cloth

Five or six caborundum stones ,different sizes and grades

a couple of slip stones

one round double sided axe stone

two washita stones

one leather straight razor strop

bald left forearm"Outside of a dog a book is man's best friend ,inside a dog it's too dark to read"

Groucho Marx

-

8th June 2007, 08:54 AM #11

Thanks to some very good advice from DC. I have 800, 1200, 6,000 King waterstones, Veritas MKII honing guide, a piece of 10mm plate glass and plasterers sanding mesh. My chisels will shave the hair off the dogs tail without waking her.

I guess at some point I will need a grinder but cant decide which.Cheers,

Howdya

Proudly supporting research into the therapeutic benefits of the Friday Thread

-

8th June 2007, 12:27 PM #12

-

8th June 2007, 05:30 PM #13

I like to keep sharpening as simple as possible because I really hate it so. But, in my eforts to develop an efficient system, I have tried just about all methods. At the end of the day I have three separate systems, which does not take into account the alternative systems (when I get bored or want to experiment as I am curious as well as lazy).

System 1

For bevel down planes and most chisels (excluding mortice, Japanese and lathe), I grind a hollow on the blade using a 6" high speed grinder.

I set the bevel angle using the Tormek jig as grinding is followed by freehand honing on waterstones. Until recently I was using King 800, 1200 and 8000. I am now using Shapton 1000, 5000 and 8000. The Shaptons are ceramic-based and required just a little water as lubricant. They remain flat very long.

I will keep them flat with a DMT coarse diamond stone (this is being delivered - they are that new). At present I use a 240 grit belt on glass. This has the advantage of being washable so that grit is not cross contaminated.

System 2

For bevel up planes (where a microbevel is used to create the cutting angle) and Japanese chisels (where the bevel face is flat), I grind on a belt sander (search for details):

This is used with a Tormek-type blade holder, but I have also recently been using a honing guide directly on the turning belt:

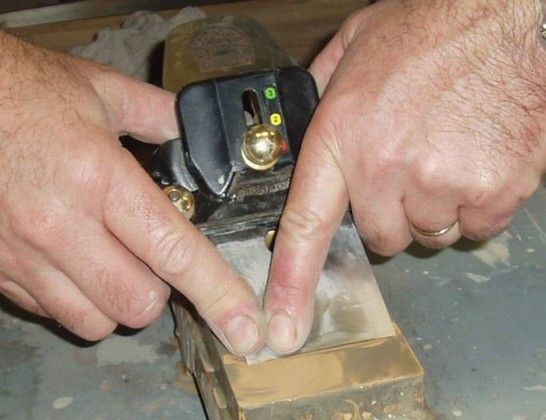

The next step for plane blades is a Veritas honing guide (MkII) on waterstones to create a microbevel. Here I am honing a fine camber for a smoother.

For Japanese chisels I just freehand on waterstones.

System 3

This is the use of a disk sander for honing lathe chisels. If I need to grind I use a 80 or 120 grit disk. Honing on a 240 grit disk is usually enough for most wood. Occasionally I add a leather strop with Veritas green rouge (.5 microns).Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

8th June 2007, 05:31 PM #14

Other

These include a hard felt wheel with Veritas green rouge (see grinder above)...

Diamond pastes of 40, 10, 1, and 0.5 microns used on Jarrah scrap

... a leather strop with Veritas rouge, and another used plain.

... and card scrapers need files and burnishers:

Did you last through that?!

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

8th June 2007, 06:41 PM #15

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

For turning tools I use the tool straight off either an 80 grit white wheel with a Sorby fingernail profile jig or an 80 grit pink wheel with a platform. Plus occasional slipstone or diamond coated rod polishing of the flute with cheap gouges.

Anything finer than that won't last seconds on Aussie hardwoods.Cheers, Ern

Similar Threads

-

Cheap tools, the plus side

By Iain in forum WOODTURNING - GENERALReplies: 21Last Post: 13th September 2009, 03:45 PM -

Sydney Wood Show Vs Canberra Show

By I_wanna_Shed in forum WOODWORK - GENERALReplies: 8Last Post: 10th April 2006, 06:16 PM -

Sharpening....A Dark Side Voyage for Beginners

By NewLou in forum SHARPENINGReplies: 200Last Post: 24th October 2005, 09:55 AM -

Blade Sharpening Survey

By derekcohen in forum SHARPENINGReplies: 0Last Post: 12th April 2005, 04:51 AM -

Sharpening Tools

By lushy in forum WOODTURNING - GENERALReplies: 9Last Post: 21st January 2000, 01:11 AM

Reply With Quote

Reply With Quote