Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 13 of 13

-

29th August 2006, 04:28 PM #1

Panel raising with the stanley 55

Panel raising with the stanley 55

Hello.... I posted this thread in a US forum first, figuring the 55 was more used over there. But still not much response. Seems like nobody like em ! ....silence is deafening or they think I'm a nutter too

(shrug) so I'll put it back here.

(shrug) so I'll put it back here.

I've got bit of a fascination for cutting profiles cleanly across grain with hand planes. Spend all day thinking about this sort of stuff. Can't help myself I'm affraid. Thought I'd write it down before somebody pinches my idea ...maybe give someone a few ideas.

...maybe give someone a few ideas.

This threads just a continuation, I suppose of these ones.

http://www.woodworkforums.ubeaut.com...ad.php?t=33429

http://www.woodworkforums.ubeaut.com...464#post326464

http://www.woodworkforums.ubeaut.com...ad.php?t=34409

This ones about raising panels. And as you know, that involves cross grain cuts. Here's what I did today using my stanley 55. Just a basic profile.

Notice how clean the cross grain cut is in that last picture. Now compare it to this sample, which was cut with a regular blade in my stanley 55 some time ago. Tear everywhere, caused by the blade presenting itself against the grain. Same old problem as described in those links above.

The solution again is to skew the blade like in those other threads. Unlike the other planes, with their smaller cuts, the blade for panel raising is a lot wider. The only way I could see to skew the blade enough to benifit the cut was by tilting the plane over.....show you what I mean.

The more you tilt the plane over, off vertical like this

the more the blade skews off square just how I want it...

Found it a bit tricky to visualise myself. But a skewed blade is just what you want for going cross grain. Bedding of planes like the stanley 46 and 39 are similar looking. The beauty of it also is that they cut nicely with the grain as well, so you can use the same plane setting to do all 4 sides of your panel, or whatever you have in mind.

So in use the plane is pushed with it tilted over...surprisingly comfortable too. Feels similar to using a sprung woodie.

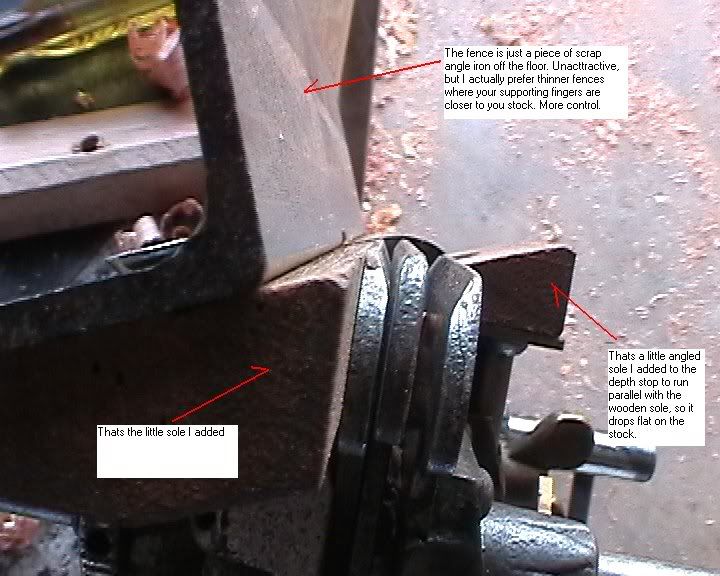

Another problem to deal with, was the instability problems of the stanley 55. There not really built to support wide cuts like panel raising. IMO, they seem ok if both skates support the work from the very beginning, else often, at least I find, the planes just too difficult to keep stable.

To solve that I decided to add a wooden sole to the adjustable skate.... just a flat sole, that cuts around the tongue common to most profiles. ie. figured I still be able to use varing profiles, whilst generally improving the 55's stability for wide cuts.

More next post.....

-

29th August 2006 04:28 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

29th August 2006, 04:30 PM #2

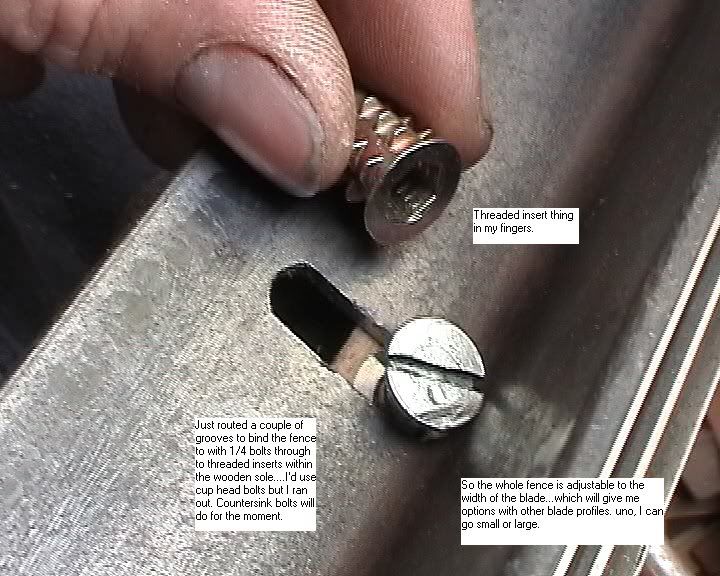

Then I just added an adjustable fence off the wooden sole.

I learn't something new, that I thoughts worth mentioning. Till now, I've thought a nicker to be manditory with cross grain work. Well, with this particular profile, I realised you don't need a nicker as long as the very corner of the blade never sees your stock. ie. the depth stop rubs first....cause its the very corner that causes tear without a nicker.

So, the nicker is tucked away unused for this profile.

Good too, because at the time I was concerned on how I'd get that nicker to work well enough with all that plane tilting going on (not ideal not cutting near vertical)

The main blade by the way was ground straight from an old file and buffed sharp.

A tip for ensuring the adjustable skate doesn't move.

Next time I'll try and cut a blade with a different profile...maybe with a fillet. Something more fancy maybe.

-

29th August 2006, 05:26 PM #3

G'day Jake,

Another beaut bit of knowledge you're passing on there Apricotripper. You could probably publish a book with the stuff you've written up.

-

29th August 2006, 05:54 PM #4

Once again a fascinating read Jake.

What's next? Have a nice day - Cheers

Have a nice day - Cheers

-

29th August 2006, 06:16 PM #5

I think you are going where no man has gone before... leaving us all in the dust, mate. I can't even begin to comment.

-

29th August 2006, 06:58 PM #6

Thanks Jake for the informative thread which demonstrates the practical uses and care of these tools and your commitment to making them work - often better than out of the box!

- Wood Borer

-

29th August 2006, 06:59 PM #7

I'm not sure I follow everything that you have put in this thread (or the others on similar topics). But the pictures of what you have achieved using your skewed blade theory demonstrahat it must work.

Thaks for letting us know about all of this stuff. One day, when I know a helluva lot more about planes and how to use them, I might feel competent to comment more deeply. But the main point at the moment is that you seem to be the only guy ever to get a decent cut out of a 55 and for that you deserve the VC and an MBE and an AM. (or a Bullsh!t ).

).

Keep it up and keep making us all feel inadequate by telling us all about it.

Cheers

JeremyCheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

-

29th August 2006, 07:38 PM #8

Apricot ... mate - you're an absolute marvel - a real 'plane whisperer'.

Greenie on the way!

jas

-

30th August 2006, 12:18 AM #9

Thanks Fellas. Like my carpatec tool. I made that I did ! ....

I'm pretty ruff as guts though... If I can do it, anybody can....

Hoping that you'd look at the principles rather than my embarrising plane asthetics. I can't seem to bring the two together yet......

But, I've found that all this blade angle visualising stuff has been invaluable for my reading grain skills in general. So I'd definetly recommend giving those principles some thought even just for that.

Please don't hold back with any ideas. Always like a chat about planes, especially if you give me an idea I can pinch and call my own.

-

30th August 2006, 11:05 AM #10

Good stuff, Jake, picked up on the "carbatec tool" bit the first time, didn't sound like you

Enjoyable reading, mate, I enjoy nutting out the principles you're explaining as well as looking at the crisp, clean profiles they create. Good stuff

Cheers..................Sean

The beatings will continue until morale improves.

-

30th August 2006, 11:43 AM #11

Thanks for all the threads you've put up on your modded planes - it's great to see what they can really do and the potential of the old gear.

-

31st August 2006, 07:25 PM #12

Ta Sean and floobyduster (whats a floobyduster ?)

nice that you liked it. Thanks.

-

31st August 2006, 07:42 PM #13

Good stuff Jake!

As to modding the 55 - well, it's a tool, and you have just made it a more effective one. Sure, some purists (collectors) might object, but I think it's just great that you apply your skills and thinking to reach the objective. Well done mate!

Similar Threads

-

History of Stanley/Bailey Bench Planes

By silentC in forum HAND TOOLS - UNPOWEREDReplies: 29Last Post: 1st December 2010, 08:27 PM -

Tuning a Stanley #140 Skew Block Plane

By derekcohen in forum HAND TOOLS - UNPOWEREDReplies: 28Last Post: 5th September 2006, 04:23 PM -

I give up - my Triton won't cut straight. Anyone work out what's wrong from this pic

By toddles in forum TRITON / GMCReplies: 24Last Post: 8th August 2006, 01:54 AM -

Raised panel finishing sequence

By Mitch Harper in forum FINISHINGReplies: 2Last Post: 25th October 2005, 11:16 AM -

Raised panel door

By hazo in forum WOODWORK - GENERALReplies: 13Last Post: 7th August 2004, 12:05 PM

Reply With Quote

Reply With Quote