Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 22 of 22

Thread: Beginner's guide to Triton?!

-

3rd March 2008, 09:11 PM #16

Don't muck around switching tops. If you decide to get the Triton router table, get the router stand.

I hear what Weisy is saying about flatness, but it did take a few years before I got to the point where my requirements exceeded its ability (and then it fetched a very nice price on Ebay).

Not so sure about the fence comment - I still think the Triton router fence is one of the strong aspects of the RTA300."Clear, Ease Springs"

www.Stu's Shed.com

-

3rd March 2008 09:11 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

3rd March 2008, 10:38 PM #17

Intermediate Member

Intermediate Member

- Join Date

- Nov 2007

- Location

- Melbourne

- Posts

- 30

Hi Stuart, that's kind of my point (question?! I don't even know any more, it's been a long day...)

The Triton router table and stand weighs in at over $375, this seems like quite a hefty whack, and I'm just trying to work out the payoff.

For that sort of money it seems like there is no shortage of options for a free-standing router table, eg:

http://www.timbecon.com.au/products/...ies-451_0.aspx

The exact pros and cons of each model are probably best left to another thread, but I'm trying to establish if there is some other advantage to getting the Triton product that I haven't considered. The only cross-compatibility I can see (other than the router table fitting the 2000) is that both the router stand and the workcentre can use the mini sliding extension (and given that I'd probably be wanting the maxi extension for the 2000, that's hardly a clincher). On the other hand, I'd say it's entirely reasonable to suspect that the Triton router table suffers from being 'backward compatible' with the 2000, and for no good reason that I can see.

Of course, for those of us that don't have all the cash up front to get set up, the modular approach of the Triton is very convenient - put up with the hassle of using the 2000 as a router base to start with, then get the dedicated base when budget permits - but I wonder if we're paying a hefty premium for that convenience?

I'm not suggesting that the Triton is a lesser router table than any of the others, but I'd like to see some more evidence that it justifies its dollars if it is essentially a standalone unit and therefore competing with them

-

3rd March 2008, 11:14 PM #18

Maxi Extension Table + WC2000 + Router Table = more possibilities ....

Maxi Extension Table + WC2000 + Router Table = more possibilities ....

Recently I had to trim some large sheets of Melamine for Pantry doors, internal doors and other kitchen fit-out panels. I found the above combination extremely useful, allowing me to very accurately plane sheet edges to match some non-rectangular existing cupboard frames. (Oh the joys of renovating

)) Using the router table on the WC2000 allowed the additional features of the maxi-extension table (larger panels / doors / sheets and longer travel) to be utilised.

)) Using the router table on the WC2000 allowed the additional features of the maxi-extension table (larger panels / doors / sheets and longer travel) to be utilised.

Being able to set this combination up in the backyard within 5 metres of the kitchen was really appreciated after the 20+th cut.

Interwood

-

4th March 2008, 07:21 AM #19

Member

Member

- Join Date

- Aug 2007

- Location

- runcorn

- Posts

- 54

Hello Wortgames. I have found that my WC2000 + Triton 235 saw can cut hard old 50m thick timber no problems. It is accurate enough for my purposes. The main negatives are that the blade can't be tilted and the NOISE.

I bought the mini extension table to use with the router table. In the end, I regret not buying the maxi. This is because I made my own router table. Why not use your hard earned dollars to buy the WC 2000, Triton saw and the Triton router. Then build your own router table as your first project for the WC.

My table top is mdf laminated top and bottom (a friend gave it to me) while the frame is made from oregon that a builder left lying around. The fence is also simple - a bolt through the fence and the table at one end so that the fence can swivel . Other end of the fence is clamped to the table. This is all that I have needed so far, and it only cost about $20 for a bit of hardware. I have 2 braked wheels on one end so that I can move it around. Screw a bit of masonite to the top when not being used and you can use the mobile table for other things.

In the end, it comes down to your personal needs and skill level (low in my case but enthusiasm makes up for it!). Geoff

-

4th March 2008, 06:50 PM #20

Intermediate Member

Intermediate Member

- Join Date

- Nov 2007

- Location

- Melbourne

- Posts

- 30

Thanks Interwood - that's a really useful point, that the Triton router table CAN be used with the maxi, just not on the dedicated router base. It would be nice to know I can use the 2000's accessories to handle large panels for the router if required.

The lack of tilt is something I was aware of and OK with. I'll happily sacrifice 'deliberate' tilt if 'accidental' tilt goes down with it! The noise is a point that I have to confess I hadn't really considered, although I'm not sure that it changes much really - I'm pretty confident that I can't afford a dedicated table saw in the near future (well, nothing of a decent quality anyway) so I still think the Triton is my best shot at straight, square cuts for now.

A great idea, except that I already have about 30 projects lined up to be the 'first'...

Now that strikes me as a bit of very lateral thinking. No need for a 'parallel' fence for a router is there? Everything is 'parallel' to a circle after all

You and me both Geoff! The biggest 'unknown' for me about the Triton stuff is it's accuracy. The idea of a million sliding bolts holding everything together worries me a bit, but by all accounts it seems to be about as accurate as the user cares to make it.

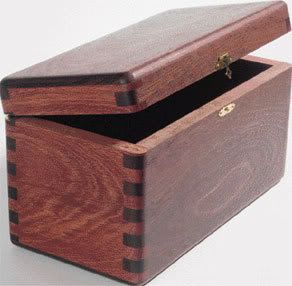

If I could turn out something like this I'd be absolutely rapt: (taken from the 'finger jointer' section of the Triton catalogue)

I couldn't even dream of producing something like this at the moment, I simply can't cut that straight (even for the panels, let alone the joints). How doable is this sort of thing in real life on a Triton?! Wishful thinking or perfectly achievable?

Thanks again for all the opinions and suggestions, it has been a huge help in making sense of it all. I'm pretty sure I'll get the 2000 and put the GMC CS in it to start with, and maybe knock up a really simple router table to get me started. Later I'll upgrade the CS in the workcentre, then later still I might get the Triton router table and finger jointer. Not sure if I'll spend the $$$ on the Triton router base, I reckon I could build a base pretty cheaply and easily, and on the rare occasions I want to use extensions etc I'll just put it in the 2000.

Worst case scenario is that it all goes up on eBay in a few months, but I'm starting to feel pretty confident I won't outgrow it that quickly

-

4th March 2008, 08:58 PM #21

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2006

- Location

- Melbourne Victoria

- Posts

- 621

Dazzler's jig is simple for cutting sheets. A shorter version with a T piece likes a draftsmans T is good for 90 degree cuts.

Start with the WC2000 and a decent saw. I have a $99 GMC and it suits me. THe 2000 is a bit limited in cross cut, (unless you make a sled) and also mitres of long boards.

I have the router table and happy with it, even though it's not 100% flat and does flex a bit. The fence is great.

For a router table you could make a simple one out of a sheet of MDF and a basic fence clamped on to see if you would use it often enough.

Most of the other accesories aren't as good as they seem. There are many dedicated units for the same purpose, biscuit jointer for one. The exception being the maxi/mini extension. I will buy one next time i'm wrestling a 2400 x 1200 sheet.

-

4th March 2008, 10:17 PM #22

Not as many sliding bolts as you're imagining. During assembly just follow the steps (and don't skip any), and it is quite straight-forward, including getting the accuracy. It takes a bit of time getting really high accuracy, but no more than any other type of TS from what I can ascertain.

Thats pretty easy - there are some tricks of the trade getting the accuracy for tight joints, but it is no more than using a sheet of paper as a shim to fine tune the finger jointer. That sort of project is well within the capabilities of the Triton.

As far as extension tables, a few years ago I put up how I've gotten the maxi to fit the router table, and I'm pretty sure someone else had a second method (and not resorting to fitting the router top onto the 2000)"Clear, Ease Springs"

www.Stu's Shed.com

Similar Threads

-

triton router and template guide

By tonysa in forum ROUTING FORUMReplies: 8Last Post: 2nd November 2007, 08:10 PM -

Changing Triton mitre guide

By AshleyM in forum HAND TOOLS - POWEREDReplies: 10Last Post: 18th November 2002, 04:00 PM -

Triton Router Template Guide

By Bob Jager in forum TRITON / GMCReplies: 0Last Post: 15th February 2002, 05:08 PM

Reply With Quote

Reply With Quote