Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 20

Thread: It's a No.1, but not a Harley

-

8th October 2014, 10:26 PM #1

It's a No.1, but not a Harley

It's a No.1, but not a Harley

A while back I purchased a group of saws, which were really a lucky dip. And a lucky dip it was as there wasn't a single bad saw amongst them. However two saws stood head and shoulders above the others. The first was obvious as an early No.8 before any of Disston's sons entered the business, but the second saw although early because of the split nuts and nib was a little more mystifying.

This was it:

Disston 6 005.jpg

We kind of identified it's origins in a previous thread (https://www.woodworkforums.com/f152/boy-toys-182912)

But the C Bishop and the No.1 was confusing primarily because of the company G H Bishop, which has nothing to do with this saw. Somehow it seemed better than I had been led to believe.

Yesterday I found my Erv Schaffer copy of "Handsaw Makers of North America." It had always seemed strange that there was no manufacturer listed as C Bishop and indeed Erv's book confirms this.

However, when you look down the list of Disston saw models there is an entry for C Bishop No.1 very early on.

I now had renewed confidence and feverishly started to clean up the plate. It also means I will have to repair the tote to remain faithful to the brand instead of replacing the handle. This is how it came up. I still have to work on the tote and hardware.

Disston No.1 013.jpgDisston No.1 001.jpgDisston No.1 003.jpgDisston No.1 007.jpgDisston No.1 009.jpgDisston No.1 010.jpg

The C Bishop was made between 1865 and 1923. This saw is 1865 - 1876 and 10ppi. SWMBO thinks I should keep this one, but at some stage it will go up for sale: I have a habit to support.

All s .

s .

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

-

8th October 2014 10:26 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

9th October 2014, 07:34 AM #2

Nice one, Paul!

But may I respectfully suggest you don't repair the tote, if you think you'll on-sell it as a 'museum piece'. I think that would detract from, rather than enhance its value, in most collectors' eyes. 'Preserve & stabilise' is their motto, so I think getting the rust off is fine, but just a gentle cleaning & waxing of the handle is probably the way to go. The scars & stains are not going to cause further deterioration, & they are silent witnesses to the life led. If it were something you intended to use, then anything goes, imo.....

Cheers,IW

-

9th October 2014, 08:24 AM #3

Thanks Ian for your opinion.

In fact I would be more than happy not to mend the tote other than gluing up the crack which is is currently held in place by two small nails.

I have seen repairs that in the rag trade would have been described as "invisibly mended," but I know my limitations and I am not up to that skill level.

Also you are right in that this saw has seen plenty of action. The scuffs on the saw plate are minor as is the staining, but they are there. The nib is miraculously intact, but much depth has been lost as it came from the era when saws were full depth.

I will give it a sharpen, in keeping with my principle that all my saws should have the potential of a "user," although I suspect no buyer will ever purchase with that intention.

The saw is far from mint, but to my eyes has a definite appeal and I can't really put my finger on the exact nature of the appeal.

BTW, I often reflect on what makes saws and other tools for that matter collectible. Rareity has to be at the top of the list, although not the only criteria. On the subject of rareity I dug up some facts on Disston's rise to prominence.

Some stats on Disston production:

1840 1000 saws/year

1850 14000 saws/year

1860 60000 saws/year

1870 150000 saws/year

1890 1500000 saws/year

1900 3000000 saws/year (Yep, three million)

That included all types of saws, not just handsaws, but it does show the exponential rise of production and it is no wonder that early saws are rare both by initial numbers and attrition.

Overall production peaked before the first world war. Hand saw production peaked in the early twenties.

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

-

9th October 2014, 11:40 AM #4

Hi Paul,

Interesting statistics on Disston Saw production... I wonder where all the apple trees came from?

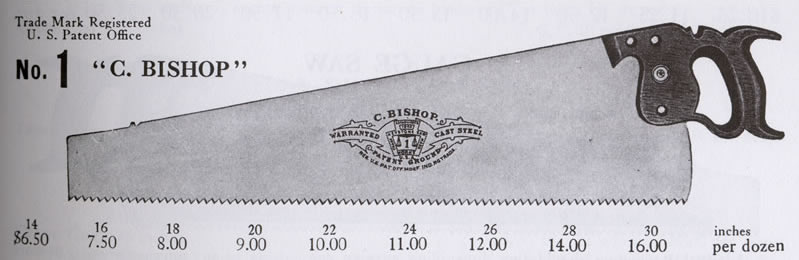

Here's the catalog entry in the 1918 Disston catalog

And a bit more info from EAIA directory...

On the subject of repair, if you intend using it, the best approach is to fix it as best you can,

There are museum curators who would insist that any repairs be made obvious rather than hidden, so that at some future date the item can be "read" and it's history decoded..

If it's not going in a museum, I wouldn't worry too much

Ray

-

9th October 2014, 02:11 PM #5

Thanks Ray.

My mind just gets boggled (I don't think it's just the drink) by where all this information comes from. I noticed that the etch had changed a little by 1918 and I would expect that the split nuts were long gone. (in fact I think they ended in 1876, which is how I could date my saw. However all that is not surprising since that catlogue extract is around forty years later. It would have been almost at the end of the No.1's time.

And for the princely sum of $1.00 you could have been the proud owner of a 26" version of this saw.

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

-

9th October 2014, 07:26 PM #6

-

10th October 2014, 08:08 PM #7

Latest pix of the restored saw. I took Ian's and Ray's advice and only did what was necessary to make it solid as far as the tote was concerned. I glued the bottom bit back on and sanded it. The two nail holes were filed with slithers of similar wood. They are not readily visible, but more because of the cunning angle of my photography than my skill

.

.

Oh; The tote was lightly finished with three coats of Danish Oil. That Beech wood is as interesting as a sandy shore really. (Got any more of that good Eastern Aussie handle wood Ian ? That's to provoke Paul Mcgee as he has been a little quiet of late, for him.)

? That's to provoke Paul Mcgee as he has been a little quiet of late, for him.)

Disston No.1 C Bishop 001.jpgDisston No.1 C Bishop 002.jpgDisston No.1 C Bishop 003.jpgDisston No.1 C Bishop 004.jpgDisston No.1 C Bishop 007.jpgDisston No.1 C Bishop 008.jpgDisston No.1 C Bishop 010.jpgDisston No.1 C Bishop 011.jpg

Some dimensions for those of you who are statistically minded (All dimensions in the old money as it seems more appropriate for a cutting device a minimum of 138 years old so no apologies there ):

):

Plate length 26" Plate depth at heel 6" Plate depth at toe 1 1/2" Plate depth at nib 2 1/8" Plate thickness at heel (toothline) .035" Plate thickness at heel (back) .031" Plate thickness at toe (toothline) .032" Plate thickness at toe (back) .029" Plate thickness at etch (toothline) .032" Plate thickness at etch (back) .029" Teeth 10ppi Rake 15 deg Fleam 20 deg

Although this saw is clearly well worn it is interesting to note that there is still 1 7/8" under the heel! This is normally the limiting factor in useability. When the handle keeps bashing on the wood it is time to give it away and buy another saw. I think the original plate would have been closer to full thickness at the toe too, but many sharpening later it is halfway into the ground zone.

Apologies for going all technical on you blokes, but if it becomes tedious just look at the pix: It's what I do. I think it stemmed from growing up with war picture library mags and Superman comics. Just to put this into perspective, I have a two volume Oxford dictionary: Illustrated of course .

.

I skim through looking at the pix. The plot is no better than the regular versions, but you know what they say "a pic tells a thousand words." Presumably, the regular version would be several volumes .

.

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

-

10th October 2014, 08:39 PM #8

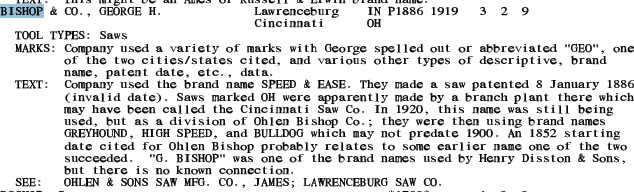

A little more information On the No.1. This comes from a 1902 advertisement. Still later than my saw, but earlier than Ray's information. I have included the full advertisement just for some comparisons.

Copy of C Bishop 1902 adv.jpgC Bishop 1902 adv.jpg

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

-

11th October 2014, 10:50 PM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jan 2013

- Location

- Tasmaniac

- Posts

- 1,470

Wondering what the value of your saw might be Bushmiller?

Personally I don't get old saws, when you can buy a reasonable one for 10 bucks these days and ditch it when it's blunt. Especially when you don't know how to sharpen them. Having said that I just can't throw away the old ones I've got even though I don't use them cause they are blunt.

-

12th October 2014, 12:28 AM #10

Artful

I understand your coments regarding the hardpoint saws and they have their place. I used to agree wholeheartedly, but now detest this aspect of the throwaway society. l also have found that the old saws are much more pleasant to use. Not only that it is quite difficult to find a modern saw in a decent length and when you do they are no longer $10: More like $30 to $40.

How much is the No.1 C Bishop worth? Good question. No idea.

The tried and trested method that is used for all secondhand goods is compare to similar items. This is difficult when there are no similar items around. We will have to see or maybe somebody else is more familiar and could hazzard a guess.

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

-

12th October 2014, 01:14 AM #11

The Bishop would be worth at least as much, most likely more than a Disston of similar age, so scouting ebay for Disston's might give a clue as to value..

I won't derail the thread with a rant about hard point saws... it will keep for another day

Ray

-

12th October 2014, 10:19 AM #12

I think you posed the question, then answered it in the next sentence, Artful.

If you can't sharpen them, 'old' saws have very limited value - limited to objects to hang on the wall & look at! I wouldn't have said this a few years ago,when you could still get a saw sharpened (properly!) at a very reasonable cost, but given the dearth of professionals capable of properly filing a saw, the only alternative is to sharpen your own, should you chose to use old-style non-hardpoint saws. I accept that's not something many folks want to do, it takes time and dedication to learn to sharpen well; I'm still only part-way up the ladder & I've been at it quite a while! Also, not all old saws are 'good', though virtually anything made before WWII, when men earned their livings with them, are vastly better to use for a long sawing session than anything you can buy in hardpoint, provided they are suited to the task in hand & properly sharpened.

Given that most folks nowadays, including myself, make use of saws powered by electrons rather than steak & potatoes for a big proportion of their sawing needs, the cheap hardpoints can often do everything required of them satisfactorily enough. But I think you would change your mind about a 10 buck saw being "reasonable" if you had to do any serious sawing with it. Compared directly with a nice, sharp, taper-ground saw of a length & heft & handle shape/position matched to the task & your arm length, they just don't cut it, so to speak. As Paul said, you are looking at considerably more than $10 for a hard-point longer than 20 inches, and anything less than 24 can be a very uncomfortable tool to use for more than a minute or two.

So there may be some wistfulness or nostalgia involved, but I assure you it's mainly practical considerations that make me prefer my 'old' saws as daily users. However, it's horses for courses, as they say, and I carry a hard-point in my ute, because it's ideal for a bit of brief use like whacking off the occasional bit of 'found' wood, & I don't care so much if it has an 'accident' (like meeing an unexpected nail ). But when at home & I've got a long board that's too heavy to go over the bandsaw or tablesaw safely, to rip or crosscut, I certainly don't reach for any hardpoint!

). But when at home & I've got a long board that's too heavy to go over the bandsaw or tablesaw safely, to rip or crosscut, I certainly don't reach for any hardpoint!

And by all means, keep the dull ones. The hardening only goes a mm or so past the gullets, and the rest is normal saw-blade quality spring steel. They make excellent raw material for card scrapers and all manner of other things like blades for trysquares and so on (if you are into tool making). You can even re-tooth them and give them a new life as a saw, though it pretty-well uses up an entire file to do that, and since they cost almost as much as a new saw, it's hardly a practical proposition...

Cheers,IW

-

12th October 2014, 10:41 AM #13

Nice pickup

regards

Nick

veni, vidi, tornavi

Without wood it's just ...

-

12th October 2014, 09:07 PM #14

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2012

- Location

- Sydney

- Posts

- 1,503

Apples were introduced to North America from Europe in the 17th century and became a widely planned crop.

The tree can grow up to 12m high with a significant trunk when grown from a seedling - which is how it would have been planted in the 1800s.

Modern crops are grafted onto rootstock which keeps the trees small and uniform in size (around 3 or 4m) so they can be picked by machine.

There would have been a lot more wood available to Disston than today.

I took my kids up to pick some Apples around Bilpin earlier this year and was very disappointed in the size of the trees!

No handles in those trunks. The apples were nice.

-

12th October 2014, 09:47 PM #15

Hiroller

I think by the end of WW2 the supply was drying up. Also other timbers were being used either because they were more decorative or supply was more plentiful. Apple was the preferred timber up to WW1 with Beech being next and then Birch. After WW2 Rosewood was the top timber (used on Disston's D15 and D115 models and EC Atkins' 400/401 models). The full grain and rich colour was infinitely more attractive. However, these timbers were clearly scarce at times too.

During WW2 (1942 -1945 for the cousins) Disston used Walnut instead of Rosewood for their top of the line saw, the D15, but renamed it for this period as the D42/D43. They tended to use steel saw nuts instead of brass as the brass was required for munitions (shell cases). However in practice during that period I think they used whatever they could get their hands on to maintain production as I have at least one D42 with nickel plated brass screws in it. Post WW2 the D15, which was re-introduced, used a plywood handle. Although this handle was vitually bullet proof I think it was used only because of scarcity of other timbers and was limited to a very short period around 1947. It then reverted to Rosewood as the timber became available again.

I would be interested to know what timbers were used after, say 1955, when Disston sold out to HK Porter.

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

Similar Threads

-

Harley & Ceblofalse

By minus459 in forum WOODTURNING - PEN TURNINGReplies: 2Last Post: 7th December 2013, 05:49 PM -

What's the best timber for a Harley??

By Moo73 in forum WOODWORK PICSReplies: 4Last Post: 19th February 2007, 08:02 PM -

The Harley

By Munga in forum NON WOODWORKReplies: 7Last Post: 4th November 2006, 07:58 AM

Likes:

Likes:

Reply With Quote

Reply With Quote