Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 8 of 8

-

23rd October 2010, 01:47 PM #1

Making the brass back for backsaws

Making the brass back for backsaws

I thought I remembered posting this once before, but maybe it was a "seniors" moment.

If you are planning to make some backsaws, and wish use a slit brass back, here is one way of doing it.

The basic set up, which I came up with, has been reproduced by some others, and you can vary things to suit your own workshop, the main component is a slitting saw and a slitting saw arbor. And some means of driving it, and supporting the work.

Here is the drill press setup, a drill press doesn't like horizontal loads, so the bottom of the arbor is running in a hole in the timber, to act as a primitive bearing to absorb some of the side forces, also the depth of the hole acts to stop the whole thing dropping out of the morse taper. Not good if the blade suddenly drops during a cut.

Here is the end view, I don't recommend making the cut as deep as this picture shows, just half way is probably more than enough.

Take care to keep the swarf from building up underneath the work, as this will make the cut off center, and could jam the blade.

I run the drill press slowly and take small cuts on multiple passes, don't get excited and try to cut too deep on one pass.

When it came time to do the forum group purchase, it was too much work for my crude setup, and I went to a friend's machine shop, we ruined a heap of brass, before finally getting it to work, the biggest breakthrough came when we bought an expensive slitting saw rather than the ebay cheapies I had been using, the better quality saws cut better and tracked properly... (sounds familar!)

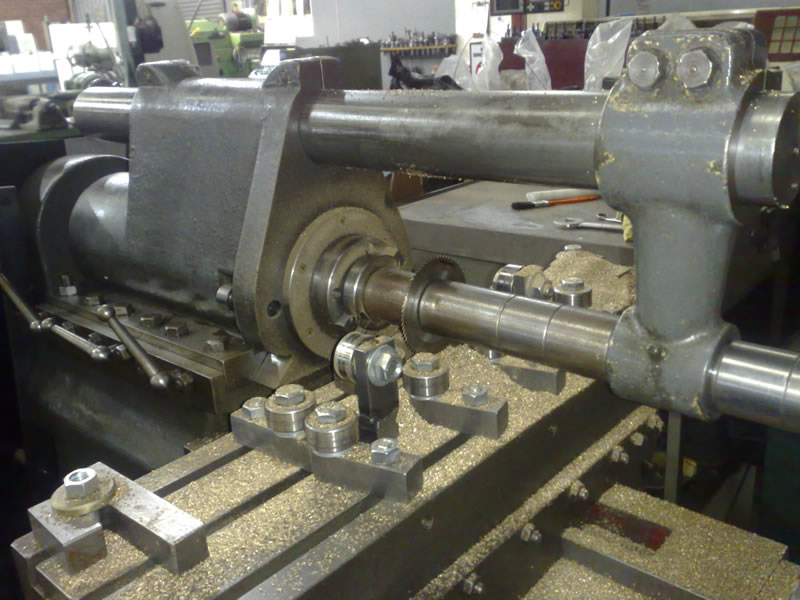

For those who have access to a mill, here is the setup we used, showing the jigs required.

The rollers are adjusted with zero clearance, keep the brass stock aligned both vertically and horizontally, with this setup we were able to slit up to 1.2m lengths consistently. Something just not possible with the drill press setup shown earlier.

Regards

Ray

-

23rd October 2010 01:47 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

25th October 2010, 10:03 AM #2

Ray - you did post a pic a long time ago, & I quickly plagarised the idea!

I also found that trying to cut the slot in a single pass caused distortion in the blade, so that the slot became progressively twisted from end to end (and yes, mine is an el-cheapo). However, if you cut the slot in a series of shallow passes, this doesn't seem to happen. It only takes a few minutes to cut a single spine, but I wouldn't want to make 50 or even 20 backs in a single sitting!

I also found that trying to cut the slot in a single pass caused distortion in the blade, so that the slot became progressively twisted from end to end (and yes, mine is an el-cheapo). However, if you cut the slot in a series of shallow passes, this doesn't seem to happen. It only takes a few minutes to cut a single spine, but I wouldn't want to make 50 or even 20 backs in a single sitting!

Mine is essentially the same as yours, but I added a couple of refinements that anyone setting it up might like to incorporate. The bottom section attaches to the drill table. This is set up & locked in place with a couple of wing nuts. I find that it's easier to set it up so that the saw blade is dead-level with the jig base at this stage (pic 1). The top piece (the bit that covers the saw & acts as a fence) is slotted so it can slide back & forth on the two hanger bolts to expose more or less blade (pic 2).

I also made a jig for holding spines while I file a chamfer on them - makes the finished job a bit more professional-looking (pic 3). You may notice the piece of steel holding the brass down is an off-cut from a Bunnie-Bob saw project....

Cheers,IW

-

25th October 2010, 10:26 AM #3

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,813

Are you guys using any lube?

I haven't tried it with brass I use Meths when cutting Ally with a slitting saw and it works very well and doesn't leave a mess.

-

25th October 2010, 10:38 AM #4

Bob - no, I haven't so far. My ancient metalworking book says you don't need lubricant with machinable brass, so I took it at its word, & it seems to be ok. I don't use cutting fluid when making the brass bolts on my little metal lathe, either. I tried using thinned oil when cutting threads (with a die), but the threads came out too tight, so went back to cutting them dry. I finally bought myself a couple of litres of 'proper' cutting fluid (a lifetime's supply for me!) a few months ago. I used it at the heavier concentration when threading and it made a big difference to the ease of cut & the quality of the threads, so when I get a drip-feed set up, I will certainly try it on the lathe. Not so sure about the slitting setup - the water in the mix will do bad things to my wooden jig. Maybe if I slather it with decking oil & let it dry thoroughly????

Cheers,

BTW - I hope you are well ventilated when using the metho, or you could end up a very happy (& very clumsy) little chap after a long session. IW

IW

-

25th October 2010, 11:12 AM #5

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,813

I was thinking more about keeping the blade cool than assisting the cutting - I guess I should have said coolant rather than lube.

For threading I find Trefolex works so well that in some cases I can use taps in a battery powered drill and set the clutch so that it does not stress the tap, 2 or three goes and the tap is done. I'v been thinking about making a die holder that would enable me to do the same thing with dies. Can't use the Trefolex on machining though.I don't use cutting fluid when making the brass bolts on my little metal lathe, either. I tried using thinned oil when cutting threads (with a die), but the threads came out too tight, so went back to cutting them dry.

That's why I was thinking Meths - it just evaporates away.I finally bought myself a couple of litres of 'proper' cutting fluid (a lifetime's supply for me!) a few months ago. I used it at the heavier concentration when threading and it made a big difference to the ease of cut & the quality of the threads, so when I get a drip-feed set up, I will certainly try it on the lathe. Not so sure about the slitting setup - the water in the mix will do bad things to my wooden jig. Maybe if I slather it with decking oil & let it dry thoroughly????

What? . . . . .Hic! - no wonder I feel a bit dizzy when I do that.- I hope you are well ventilated when using the metho, or you could end up a very happy (& very clumsy) little chap after a long session.

I usually turn on the DC while I'm doing it. The amount I use is small so it cannot reach combustible levels.

-

25th October 2010, 12:31 PM #6

I made a die holder from a piece of scrounged aluminium, after an idea I saw on a machinists' forum. It slides on a 3/8" rod chucked in the tailstock, to keep it aligned & concentric - works like a charm for threading the sawbolts! I did it as one of my first turning "exercises" after I got the lathe - took me all afternoon (including making the mild-steel boring bar to dig out the recess for the die nut), but you would probably make it in 1/2 an hour....

'Twasn't combustion I was worried about - it's your liver!

Cheers,IW

-

25th October 2010, 12:47 PM #7

Something like this perhaps?

-

25th October 2010, 12:49 PM #8

Similar Threads

-

Saw steel suppliers for brass back saw makers

By lightwood in forum HAND TOOLS - UNPOWEREDReplies: 57Last Post: 18th April 2016, 07:42 PM -

Video of putting a brass back on a saw blade

By jmk89 in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 0Last Post: 7th May 2010, 11:32 AM -

Group Purchase - Brass back stock for sawmakers

By RayG in forum HAND TOOLS - UNPOWEREDReplies: 213Last Post: 14th September 2009, 11:58 PM -

Backsaws: Brass or Steel. Which is better?

By tomnewby in forum HAND TOOLS - UNPOWEREDReplies: 18Last Post: 28th July 2008, 10:11 AM -

Of brass and plane-making

By Green Woodchips in forum HAND TOOLS - UNPOWEREDReplies: 13Last Post: 3rd April 2006, 12:58 AM

Reply With Quote

Reply With Quote