Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 13 of 13

-

5th March 2007, 07:35 PM #1

Cutting floating tenons and dowels with a bead plane.

Cutting floating tenons and dowels with a bead plane.

Found another use for a bead cutter other than prettying up edges.

Floating tenons are all the rage at my place at the moment

This is how I've been doing them lately, this time with a record 50.

With trued timber, with its thickness spot on, just depth out the bead one side.

Then just flip it and do the other side.....end up with this sort of thing.

Then you just rip it off on the table saw.... if you've got a dodgy table saw like mine you may be inclined to overcut then creap the thickness spot on to the mortise width via the thicknesser.

That makes a nice fit to match the mortises cut off my horizontal mortiser (just an old shopsmith)

Here's another thing I tried.......Making dowels. Essentially the same process. Seen it done in the manuals, but never really had a need to do. Actually, don't need to do it now really. Just showing off uno.

From that 3/8" floating tenon I just thicknessed some scrap a little wider.

Then just bead one side first then depth out bringing that little bridge of timber there as thin as possible. You just slowly raise the depth stop between passes......the fear of course, is that this little bridge will get too thin and the skate will break through and the plane will crash....and you'll swear....and the dowel will be torn up...and you'll have to do it again, like I had to do (never show the stuffups eh. )

)

Anyway when I dared not go any further, I just sliced it off with a knife and trimmed the little line off with a block plane.

What you could probably do anyway, if you fear its not perfectly round, either because the blades not sharpened right, or whatever, is just make this beading process with the plane a preliminary step to using say a doweling plate.....ie. whip them up close to perfect with the plane, then nock them through the plate. Just an idea.

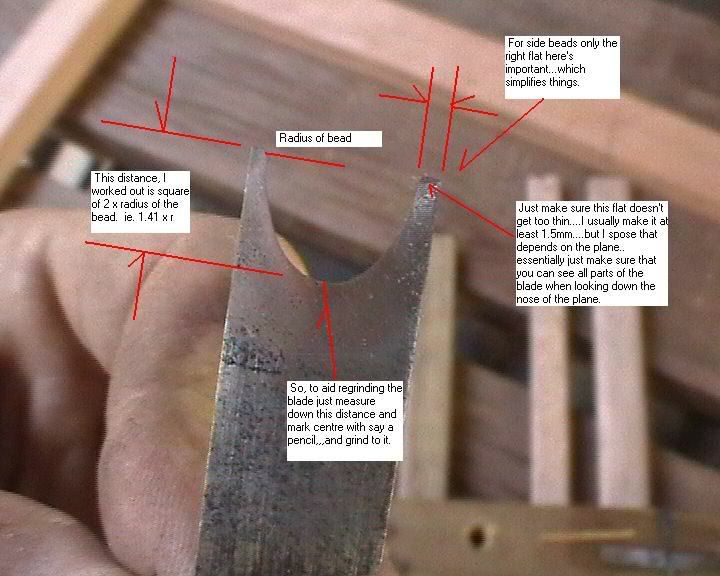

You gonna have to address the profile of the blade......From the factory they don't seem to be ground right, to form a perfect half circle.....a lot of them anyway.

Basically, due to the 45 degree bedding of the plane you must sharpen this curved profile elongated.....ie. you've got sharpen it egg shaped in order to cut a circle. ..... easy to work out, thankgod........its just the square of 2 times the radius.

eg. a 1/4" blade (cuts a circle with a 1/4" diameter) has to be sharpened back about 4.5mm (3.17 x 1.41)

Hope that made some sense.

-

5th March 2007 07:35 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

5th March 2007, 07:48 PM #2

Jake

That's bl**dy brilliant - I had seen the dowel idea in the books, but thought it was a bit optimistic. But you've had the guts to have a go and it works.

Only one question - when you say "square", I take it you mean "square root" - my recollection is that 1.14 is about the sqr of 2.

Well done - are you going to use this to make 2mm dowels?

JeremyCheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

-

5th March 2007, 07:52 PM #3

Thanks Jeremy.

I don't really know. Its just what my calculator says. Kids have dropped it a few times....maybe its stuffed.

I was going to, but it meant making up an new blade. So I ended up just chucking meat skewers through a makeshift dowel plate like was suggested to me......

-

5th March 2007, 10:59 PM #4

Hey Jake

That's terrific work.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th March 2007, 03:06 AM #5

Very well done, Jake!

I've made floating tenons but never thought to actually try doing dowels. Would have saved a lot of heartache of making some wood dowels for some projects I did and used a lathe. I had wanted to use a specific species. Duh!

Take care, Mike

-

6th March 2007, 05:31 AM #6

Senior Member

Senior Member

- Join Date

- Sep 2006

- Location

- Bookham, Surrey, UK

- Age

- 79

- Posts

- 137

That's great, Jake. Probably much quicker than shaping the floating tenons individually.

Cheers

Paul

-

6th March 2007, 05:58 PM #7

Thanks.

-

6th March 2007, 09:06 PM #8

Well done Jake, I enjoyed that

...and another chapter for the book you should be working on!

...and another chapter for the book you should be working on!

Cheers,Andy Mac

Change is inevitable, growth is optional.

-

6th March 2007, 10:59 PM #9

Ta Andy. A book !

..... the thought of that makes me nervous. I'm too green to be doing such things.

..... the thought of that makes me nervous. I'm too green to be doing such things.

Did you manage to get that big shave going ?

-

7th March 2007, 03:33 AM #10

Jake, a book or "use manual" or booklet of "The Random Thoughts of a Crazed Handtooler" is not a bad idea.

Why? Because you have a fresh way of approaching problems, tool use, and are fearless about modifications--which is one thing I like about you.

An editor of sorts would be who is responsible of compiling and making the flow into a so-called logical order.

Take care, Mike

-

7th March 2007, 09:37 AM #11

Senior Member

Senior Member

- Join Date

- Sep 2006

- Location

- Bookham, Surrey, UK

- Age

- 79

- Posts

- 137

I'd buy a copy

Cheers

Paul

-

7th March 2007, 11:31 PM #12

yeh, I can go overboard with my ideas.....I get very stubborn you see.

Did I tell you, I've got a new job Mike . I brought home a ute load of timber today after work. The boss called it ' Jakes Pile ' ... Took a photo, so I'm going to start a new thread on it after this

Heres' a pic of the floating tenons in use, I forgot to include amongst the above.... Not that its needed I suppose, but I feel its important to show the final result.

-

8th March 2007, 03:42 AM #13

Doesn't get better than that.

Off to see the new thread...Mike

Reply With Quote

Reply With Quote