Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 27 of 27

Thread: Wanted....Hand plane tuition, SA

-

11th March 2021, 09:51 AM #16

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2019

- Location

- Brisbane, Australia

- Age

- 43

- Posts

- 519

Hi Lappa

I'd be interested in a photo the jig with the belt sander.

How do you keep the jig off the sander bed; does it sit just off the end of the belt?

-

11th March 2021 09:51 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

11th March 2021, 11:02 AM #17

Woodworking mechanic

Woodworking mechanic

- Join Date

- Jan 2014

- Location

- Sydney Upper North Shore

- Posts

- 4,469

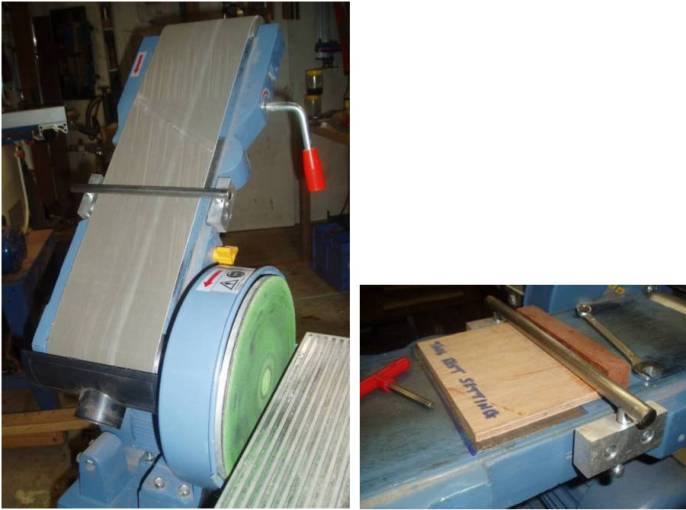

There’s a “bridge” that sits under the belt assembly. The pivot heights are adjustable to get the angle in the ball park when initially setting up.

2F8AC178-3FA1-4EBB-809C-9D777C30FC9F.jpg

A rod is placed through the pivots

D637787C-1DD0-444D-BE1E-B17385C1040C.jpg

The Trojan honing guide was modified to it would connect to the rod

2139058C-7DE1-414D-8B75-9F1A83CDFD0B.jpg

All set up and ready to go. I place a magnetic angle display on the blade then adjust the blade in the guide to get the correct angle.

8062E9A8-4B0D-481E-8840-5C32B7D17D20.jpg

-

11th March 2021, 11:58 AM #18

There was a thread on here many years ago on using a belt sander as a sharpener. I think Derek may have started it but that was before the great picture loss the forum suffered. I used the method myself for a while. The crossbar was a kitcken drawer handle from bunnings. It actually is really good at doing primary bevels. One thing to be aware of however is fire risk if that machine is also used for wood sanding. Sparks and fine wood dust are a bad mix as I found out.

Regards

John

-

11th March 2021, 12:02 PM #19

-

11th March 2021, 12:13 PM #20

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

David Weaver - DW on this forum - has in the last year or so developed a new method of sharpening and everyone who has tried it has been rewarded with a new level of sharpness for very little effort, very short time expended and minimal money, in fact very little money. Some experienced users have found that sharpening plane blades can be tricky but sharpening chisels is a very quick simple operation everybody who tries it comes to grips with straightaway.

He was pursuing a method that enabled softer blades to stay sharper longer and apparently it does this very well.

This his YT channel David W - YouTube

Using a Buffer to Gain Chisel Durability Without Dulling an Edge or Increasing Cut Resistance - YouTube

The Unicorn Edge - What's Happening with the Buffer? What abrasive? - YouTube

Unicorn makes junk plane irons pearls - YouTube

One more method to buff plane irons - YouTube

https://www.youtube.com/watch?v=aYm77Hwlifg

I think there can two ways to view David's methods for a beginner and that is to learn sharpening that works and is SHARP or to dive right in and forget the rest because for sure that is going to be the cheapest and it just about guarantees a good result in short time with minimal expense. David is most probably one of the most informed people, well above the YT experts who think they are and he has a wealth of knowledge in his videos on setting up hand planes. He recently did one on setting up a brand new modern Stanley, that's the plane everyone reckons is useless in every respect and it was a fairly simple straight forward process and most importantly it worked.

Have at the links above and especially his plane set up videos because they are the best out there. The one thing above all is learn what sharp is because if you don't have a target then you won't recognise what sharp Isn't. Thinking about it recognising what sharp isn't is most probably the most important of all.CHRIS

-

11th March 2021, 12:38 PM #21

Woodworking mechanic

Woodworking mechanic

- Join Date

- Jan 2014

- Location

- Sydney Upper North Shore

- Posts

- 4,469

The bottom has two pieces of timber that sit tightly against each side of the body (two red arrows) then there is a piece of timber across the top (one red arrow) that has been height sized so when the belt assembly comes down and clips into place the jig is locked firmly in place.

FAE0B4F3-8668-4EEF-889E-071DADB93566.jpg

Orraloon’s post reminded me that I posted about this setup years ago.

-

12th March 2021, 01:03 PM #22

Its all horses for courses, Chris. We have experiences, we change our minds, we move on...

My presently preferred sharpenning technique, in detail, is:

- establish primary bevel on DMT duosharp extra course diamond plate using Veritas honing guide,

- remove grinding scratches with DMT duosharp course plate with honing guide,

- sharpen on wet Shapton waterstones - 800, 5000, 10,000 grit - progressively,

- Hone with green paste on MDF.

I only use the diamond plates to establish, repair or change the primary bevel; after that its just the waterstones.

Works for me, at this point in time.

-

12th March 2021, 01:14 PM #23

Originally Posted by GraemeCook

Originally Posted by GraemeCook

My bad, Lappa; should have explained that scary sharp is a common name for a sharpenning system using sandpaper on a flat backing sheet - glass, tile or steel plate.

It is not directly a comment on the degree of sharpness obtained. But it could be!

-

12th March 2021, 04:34 PM #24

Woodworking mechanic

Woodworking mechanic

- Join Date

- Jan 2014

- Location

- Sydney Upper North Shore

- Posts

- 4,469

My comment wasn’t directed at your or your comment intentionally but to the term “scary sharp” that’s been used for on many forums for years.

-

12th March 2021, 07:51 PM #25

The Belt Sander Grinder MkI: http://www.inthewoodshop.com/Woodwor...rinderMkI.html

The Bench Sander Blade Grinder MK II: http://www.inthewoodshop.com/Woodwor...erMK%20II.html

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

12th March 2021, 08:08 PM #26

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2019

- Location

- Brisbane, Australia

- Age

- 43

- Posts

- 519

Thanks Graeme

There really is so much to learn by doing. A piece of advice I recall reading on Derek's site that I, with respect, think is profound is that you should give a sharpening method a long period of time to see how it works over time.

I am constantly discovering new things by experience. For example I was having a terrible time flattening and polishing the backs of chisels. I would go nuts on a diamond plate until my arms were worn out.

I decided to switch to belt-sander paper on a flat granite block, bearing down hard, and using a rubber stick to clear the paper. Then switching to wet+dry paper. Within 10 minutes:

PXL_20210312_074704565.jpg

The difference? I think it was bearing down hard (instead of going back and forth, back and forth), which you can't really do on a 6" diamond plate as the whole blade doesn't really fit on the plate unless you're only moving it a small distance that doesn't work with hard downward pressure.

So what turned from a frustrating "why can't this work for me!" problem turned into a short, not-unpleasant task with the right gear. In short I was trying to use my arms to move it a huge number of times without the experience that it will actually happen much quicker than fewer strokes, bearing down hard. (A thick granite plate works well for this because you can really press down hard.)

And of course, the theory lines up. If you are essentially pushing two hard materials against each other trying to make one (the sandpaper/diamond grit) remove material from the other (the metal) as they rub past each other, of course you want hard pressure as opposed to soft pressure.

Chris

-

13th March 2021, 04:26 PM #27

Fully agree. But this does not only apply to sharpening.

I have 8 inch (200mm) DMT Duosharp diamond plates and wet grind the backs of chisels and plane blades, holding the blades at an angle of about 15* across the plates. this gives me a "stroke" of almost the full length of the plates. As soon as plates look dirty grey/black I wash them with a water spray. If stage 1 flattening takes more than 2-3 minutes I start to question whether that blade is too curved to warrant fettling.... I am constantly discovering new things by experience. For example I was having a terrible time flattening and polishing the backs of chisels. I would go nuts on a diamond plate until my arms were worn out. ...

Then through the water stone grits. I only use honing paste when I am showing off and really want a mirror back!

When I was using the "scary sharp" technique (sandpaper on a glass sheet) I variously used belt sander paper, wet & dry sandpaper (black) and aluminium oxide sandpaper (white) - all were routinely used wet with water washing as they became dirty or loaded up with steel filings. All worked equally well. I moved onto diamond stones so I would not have to buy sandpaper.... I decided to switch to belt-sander paper on a flat granite block, bearing down hard, and using a rubber stick to clear the paper. Then switching to wet+dry paper. Within 10 minutes:

PXL_20210312_074704565.jpg

The difference? I think it was bearing down hard ...

Progress. But your technique, what you have learned, is probably more important than the gear. I have had this experience multiple times, sometimes followed by puzzling set backs....

So what turned from a frustrating "why can't this work for me!" problem turned into a short, not-unpleasant task with the right gear. ...

Different from my experience, Chris. I use moderate to firm pressure and concentrate on maximising the length of the sharpening stroke, keeping the blade absolutely flat on the plate and maintaining the same pressure all over the blade.... In short I was trying to use my arms to move it a huge number of times without the experience that it will actually happen much quicker than fewer strokes, bearing down hard. (A thick granite plate works well for this because you can really press down hard.) .....

Chris

Similar Threads

-

Wanted: Someone to Refurbish Old Hand Plane

By michhes in forum HAND TOOLS - UNPOWEREDReplies: 13Last Post: 26th January 2015, 09:15 AM -

Hand plane advice wanted.

By Rattrap in forum HAND TOOLS - UNPOWEREDReplies: 34Last Post: 14th August 2010, 09:56 PM -

Router tuition wanted in Sth Oz

By BrianT in forum ROUTING FORUMReplies: 3Last Post: 6th September 2003, 01:16 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote