Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 15

Thread: A home-grown bowsaw

-

17th February 2011, 10:25 AM #1

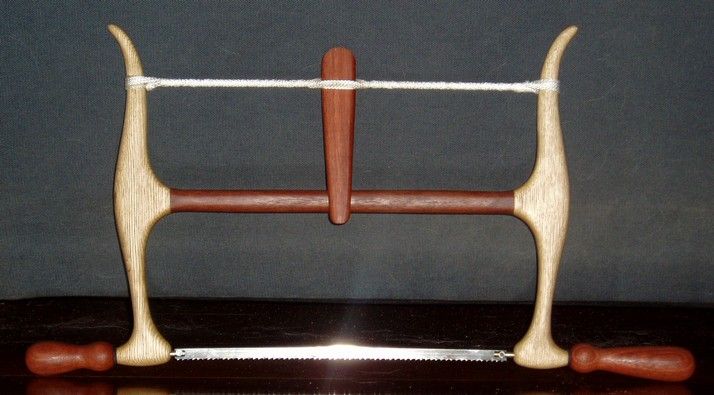

A home-grown bowsaw

A home-grown bowsaw

There have been a few discussions on saws for cutting out most of the waste from dovetails, etc. and the most favoured seems to be a coping saw in any of its various incarnations. I’ve used a small bowsaw, built to take coping saw blades for many a year, and recently upgraded it (URL?). However, I’m not very happy with the blades we can buy these days – they are poorly sharpened to start with. This is fairly easy to fix, if you have a vise that can grip the blade, but the metal is quite soft, and so they lose their keen edge very quickly. The soft steel also means they distort easily unless you put a huge amount of tension on them a la the fancy saws Derek has recently lauded.

So I was looking at an offcut of sawplate left over from my backsaw-making frenzy, and started thinking “Why not?...”. The piece of .5mm plate exactly matches my favourite dovetailing saw, and was about 10mm wide & 250mm long, so I cut some teeth on it (15 tpi, which is the same as the DT saw) and then cut a slice off, leaving a blade a bit less than 5mm wide. The brass end bits are salvaged from a set that went wrong on me. I had to cut off & add to one piece, which is the main reason for the overly fancy extension for a turning knob (which seems to work very well ). (pic 1).

). (pic 1).

Next job, find some suitable wood for the frame. I have these scruffy Wattles in my yard (A. leiocalyx as far as I can identify – pic. 2) that have a habit of growing up quickly, dying, & falling over, so I salvage what I can from them for chair parts, etc. They are never more than 150mm diameter, often full of grub-holes, and have no straight sections longer than 600mm at the best. However, the wood is quite fibrous & tough - see how you get a ‘greenstick’ fracture even with dry wood (pic 3.), & ideal for the purpose. I could even use the slight bends to advantage to orient the grain around the curved end pieces (pic 4).

(continued)IW

-

17th February 2011 10:25 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

17th February 2011, 10:30 AM #2

New bowsaw part II

New bowsaw part II

So, skipping the boring bits of shaping, scraping sanding & oiling – here is my new saw . (pic 1 ). I would have liked to make the blade a wee bit thinner, but given my crude facilities for slicing thin spring steel, this is the best I could do.

I gave it a test run on a mock DT cutout, and am quite pleased with it – despite the slightly wider than desired blade, it turned well enough to remove all but a sliver of waste rom a fairly narrow space, in two cuts. Hand pressure was enough to pare out the remaining bit of wood.

So this really is a "home-grown" saw! Now, the only remaining problem is where the heck I’m going to fit it in my over-stuffed tool box????

Cheers,IW

-

17th February 2011, 01:26 PM #3

Nice job Ian

How exactly do you slice spring steel plate?

-

17th February 2011, 03:27 PM #4

Another fine tool from the IW Toolworks!

And another tool I'd like to make.

.

And another tool I'd like to make.

.

I know you believe you understand what you think I wrote, but I'm not sure you realize that what you just read is not what I meant.

Regards, Woodwould.

-

17th February 2011, 03:57 PM #5

Hi Ian,

That looks beautiful as always... I'm almost inspired to try and make another one..

The last bowsaw I made broke.. I really must get back and fix it. I like the thin blade from spring steel... (very cute indeed)..

One thing I found, was that with turning saws like this, you want the blade to rotate to a position, then stay where you put it. A slight taper on the pins that hold the blade fixes this, so that as you tension the blade it "locks" into the taper and stays fixed at whatever angle you have set.

The other thing, I must remember to do, and that is to use riven stock rather than sawn stock for the arms...

Regards

Ray

PS... What about a right angle bend to do the Frank Klaus trick?

-

17th February 2011, 04:48 PM #6

Hi NCA - by the method RayG instructed me in: Clamp said plate between two straight pieces of 3/16 steel flat with the 'good' side in the steel clamp, then run along it with a 1mm cutoff wheel in a 10mm angle grinder. If you are deft & don't dawdle with the cut, the heating is minimal. I've found if you want to use the cut off piece, you need to file away about a 1/2 mm because it will be hardened in patches where itgot a bit hot.

Hi Ray - yes, Woodwould has mentioned the tapered shaft idea previously. I would have tried it with this one, but I was using brass that was already turned to the size I wanted, so I resorted to my long-time method of slipping an O-ring from a water tap shaft between handle & frame. That works well, too, and is a bit easier than turning tapers (I'm still a relative novice on my metal lathe). I did put a taper on the piece that goes through the end knob, to lock it in place on the shaft.

If you choose your piece carefully, sawn should be ok, but if you get any significant runout at the points of high bending stress, it ain't good, alright. What wood did you use? I've found Blackwood to be another wood that works well - light but strong.

I tried that bent blade trick way back when I first saw it in FWW, but in my hands, it just didn't work well at all. For the turning sawing I do, a narrow blade works well enough & I can still sort of control it. This blade easily cuts a 5-6mm radius, which is about all I ever need.

Cheers,IW

-

18th February 2011, 12:07 AM #7

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Hi Ian. If you ever need some bow saw blades I have a heap available in my workshop. I purchased these from the U.K a long time ago. . They are new/old stock blades. i think they are about 325mm total length and close to 5mm in width. Would need to check the tpi. They have the pin holes on each end for securing. Will get more details if needed. The offer is extended to RayG and Woodwould if you need some.

Stewie.

-

18th February 2011, 08:20 AM #8

Stewie - thanks for the kind offer, but I'm ok for blades forever, I think. I have a few more slivers of leftovers from back saw manufacturing, and an endless supply in some old bandsaw blades I saved expressly for the purpose. These are of even hardness all the way through, so can be cut & sharpened quite easily. I have a 12" bowsaw I made at least 30 years ago, and recently replaced the first blade, so they are not something I use up in a hurry, it seems!

I keep meaning to make myself a good-sized frame saw - I saw these being used to great effect when I worked in the back blocks of a couple of Asian countries. I guess I would need an apprentice to use it, though...

Cheers,IW

-

18th February 2011, 08:26 AM #9

Stewie, PM sent.

.

I know you believe you understand what you think I wrote, but I'm not sure you realize that what you just read is not what I meant.

Regards, Woodwould.

-

18th February 2011, 01:48 PM #10

Hi Ian,

I had another look at the grain direction on the arms of yours, and yes, you have chosen very carefully to get the maximum amount of grain running parallel to the arms.

The wood I used was english ash ( from a tree in the backyard homegrown like yours ) which I have used a lot for hammer handles and such and it's just perfect timber for the job, light, strong, a little bit springy.

) which I have used a lot for hammer handles and such and it's just perfect timber for the job, light, strong, a little bit springy.

I'll have to give it another go..

Stewie,

Put me down for a blade or two, we'll sort out details later. I' plan to get your saw plate posted this afternoon.

Regards

Ray

-

21st February 2011, 06:49 PM #11

1. I'll 're-post' this to amplify the point that old bandsaw blades are idea for bowsaw blades.and an endless supply in some old bandsaw blades I saved expressly for the purpose

1. I'll 're-post' this to amplify the point that old bandsaw blades are idea for bowsaw blades.and an endless supply in some old bandsaw blades I saved expressly for the purpose

2. Framesaw and re-sawing ~ one of my bowsaws has a 'blade kerf to centre spreader' throat of just over 6", and has a design that allows it to fulfill the function of a framesaw due to both 'throat' and its 'balanced/symmetrical design'.

Putting the fact that it is "unwieldly and needs an assistant or far steadier hand than I have' aside, I'll choose a plough plane over the bowsaw due to the speed of the plough alone.

Of course, I'll not critizise anyone using a framesaw 'because they want to'... after all if I was interested in speed and speed alone I would use a bandsaw or circular saw. (but then I'd have to vacuum the back room which functions as my 'shed' far more often

(but then I'd have to vacuum the back room which functions as my 'shed' far more often

)

)

Ian,

Well done on the bowsaw, what I take away from it is a) the use of 'trimmings' and b) grain orientation.

-

23rd February 2011, 09:06 AM #12

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

Another fine looking tool Ian!!

I have a lousy coping saw that is due to hit the recycle bin. Will have to duck over to see you when I get more organised and get some tips on mking one of them there saws.

-

23rd February 2011, 02:13 PM #13

I'm sure there'd be a few Brisbanites that'd queue up for that opportunity...

Regards,

Denim.

-

23rd February 2011, 05:25 PM #14

Damn your eyes Ian Wilkie!

The guilt ... the guilt ...

Your saw .. and blade .. are fabulous. They tempt and taunt at the same time. I want one .. but don't really need one. However, I have these pieces of brass, lovingly crafted for a bowsaw by you, works-of-art in themselves (you must see them my fellow inmates), and I must do them justice. I want to do them justice.

The blade is indeed a factor. I have made one bowsaw before using a 6 tpi 1/4" bandsaw blade. It works OK, but this is not a good blade. Your 15 tpi is much, much better (keeping in mind that my effort - several years ago now -was aimed at sawing dovetails). A pretty saw, but not really inspiring as a tool.

I know I can do better than that. So, a blade? I shall confer with Joel at Tools for Working Wood.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

23rd February 2011, 08:49 PM #15

Funny - that's something like LOML says on occasion, so I give the same answer - "Have I done something wrong??"

No need to feel guilty, 'ol buddy - if you have half as many projects waiting to be finished (or even started) as I have, then heaven help both of us. I've been indulging myself quite selfishly, as I segue into this retirement caper. I ought to be working hard on several major projects, but have found all sorts of excuses to just play about in the shed.

Damn - the weather report says tomorrow will be fine - I may have to cut the grass........

Cheers,IW

Similar Threads

-

Tame Aussie Grown Olive

By Penpal in forum WOODTURNING - PEN TURNINGReplies: 10Last Post: 13th May 2010, 08:47 AM -

Cherry - NSW Grown

By crazyhorse in forum MUSICAL INSTRUMENTSReplies: 2Last Post: 12th September 2007, 12:41 PM -

Grown Mirror and Table

By blackash in forum WOODWORK PICSReplies: 31Last Post: 4th January 2007, 02:17 PM

Reply With Quote

Reply With Quote