Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 81

Thread: Liogier handlemaker rasps

-

10th March 2012, 01:49 AM #1

Liogier handlemaker rasps

Liogier handlemaker rasps

Near the end of last year I suggested to Noel Liogier that his company manufacture rasps for making handles. Up to that stage the only company I knew of that make these was Gramercy, and they had not had any in stock for quite a while.

Liogier rasps appear to have made a recent rapid emergence onto the world woodworking stage although they have been as well known and respected in Europe as is Auriou. In general they appear to be of similar quality, but slightly less expensive than their better known cousins.

A few weeks ago Brett Gregory, who has been doing all the footwork, sent me 5 rasps for evaluation. I had to put them aside while building the bench. As a result I have only had a couple of days to play with them and come up with a meaningful assessment process.

The handlemaker rasps differ from others by their curved blades. They are also only stitched on one side, the other being "safe" - no teeth. Both the curve and the safe side are to enable one to rasp inside a handle without touching (and scoring) the opposite side.

The teeth are measured in "grain", with more grains leaving a smoother finish. The coarsest rasps would be a 1, and the smoothest a 15.

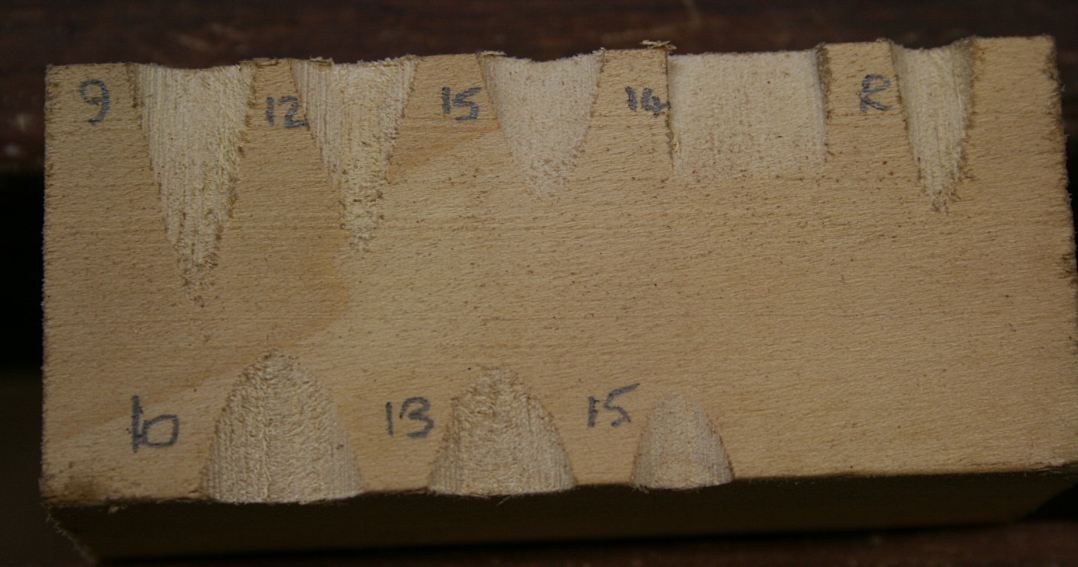

The centre three rasps are 15, 12, and 9 grains. There is a flat/curved 14 grain rasp to the left and a coarse rat tailed rasp to the right.

Here is an illustration of the penetration by one of the handlemaker rasps and a straight Auriou ..

First in a plane handle:

... and then in a saw handle:

My brief experience with these curved rasps indicated that the curve was just right. The exception here was the flat/curve, which I thought to be too flat.

Second from the bottom, flanked by the half-round curved rasps:

The value of this rasp would be when rasping the outside faces of the handle.

For comparison I had my Aurious. Here is a sample of the performance of all the rasps on Poplar:

Performances between the Liogier (top) and Auriou (bottom) are very similar grain-for-grain, given that the rasps are different grains. That is a 14 is similar to a 15 but with slightly more coarse, etc.

The question someone will ask is "how many rasps does one require?". I liken it to sharpening a blade: a coarse medium will hog waste away quickly. Then, however, one must remove the marks this process creates, and continue this process until you reach the finish you desire.

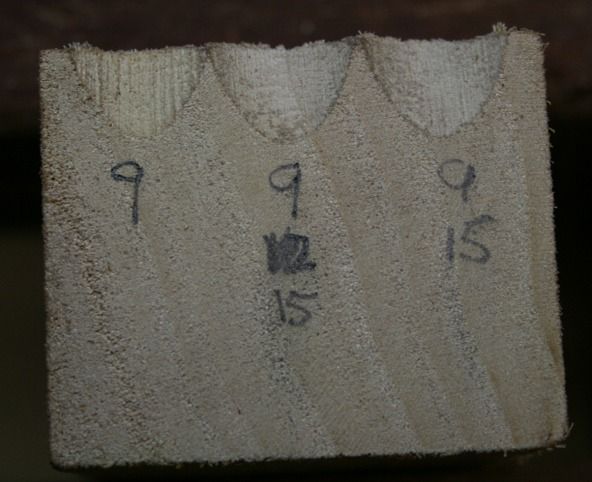

In the picture below the first stroke is with a coarse 9 grain rasp. The second is the 9 grain followed by a 12 and 15. The third is the 9 grain followed by only the 15 grain.

It can be seen that the three-rasp process leaves the best finish, and that jumping from a 9 grain to a 15 grain will leave a evidence of the 9 grain teeth.

Downsides? I think that the handles on two of the rasps was too small. Here they are alongside my Aurious, which have Lutz file handles.

Only brief comments about the rat tail rasp - there was only the one coarse version. It removed waste very rapidly. It needs to be partnered with a lesser coarse rasp to bridge the gap to the handlemakers versions.

In conclusion, these are very nice rasps, ones that I could certainly use in my workshop, and I shall be placing an order for a similar set.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

10th March 2012 01:49 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

10th March 2012, 10:48 AM #2

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

Thank you Derek for this informative appraisal.

BT

-

10th March 2012, 05:26 PM #3

Hi Derek,

Good write-up. After having held these very rasps, (but not used them) I also felt that I would have better control if the handles were a little larger.

Perhaps if the handle size was optional when ordering that might be useful.

They certainly appear to provide the ability for much longer strokes when shaping a handle, due to the greater curve. This would allow for use of more of the rasp length when making handles and therefore not place most of the wear on the front section as with the Auriou rasps.

I have been hoping these rasps become available as I have some handles I would like to make down the track and I need all the help I can get. Might also be looking at an order of some.

Cheers

Pops

-

10th March 2012, 06:57 PM #4

Hi Derek, yes I agree too about the handles, and the increased curve required in the Curved Flat (?). You can actually have any of the 4 sized handles, and the quality of the handles is being addressed. In fact Noel told me last night that he has only quite recently been putting handles on his rasps. Or of course you can make your own pearlers, or berate IanW into a small job. This is the result of a not-so-small job that Ian did for me:

What a fabulous job eh? 45 handles in 5 sizes to my hand specs, and in no less than 14 different species. Thank you so much Ian - well above the call etc. There is a really lovely personal aspect to the She-Oak that he used but I'm not sure if he wants me to tell - have to ask him. He knows that I have a thing for Copper, and you should see some of that She-Oak, with a copper ferrule set against the navy blue of the Sapphire coating - WOW! Btw, isn't Copper Ferrule a contradiction in terms?

I only requested the one Ratty from Noel because it was just an idea that I had - it just sounded like a damned useful tool. Same story with the Flat Curved, I thought that it would slot into the package quite nicely.

Pricing: Noel has just had a 2.8% price increase, which is no big deal especially as the A$ has significantly strengthened against the Euro. The Sapphire coating price however has had a pretty decent hit (up) and this is beyond Noel's control. I'll be posting separately about that, but the prices for the curved rasps are the same as the straight versions. What Noel gains in not stitching one side he more or less loses with a much trickier tempering process due to the curve. I meant to discuss a Handle Maker's Package last night but we got involved in other discussions. Something like x% discount for a set of three and y% for a set of 5-6. It would not be a big discount (definitely single digit) due to the hand-made nature of these, but we'll see what transpires.

Derek, what would be your perfect set? Clearly it would include the three Half-Rounds (#9, #12, #15), but what do you think would make a completely useful package for Handle Making (assuming cost no object)?

Did you notice if the Sapphire coating assisted with clogging or is that a bit tricky to determine with nothing to directly compare to?

Thanks for your review - well done and comprehensive as usual.

Regards, Brett

-

11th March 2012, 10:55 AM #5

Guess I'd better weigh in with my 2c worth.

With respect to handle sizes: The only way to please all comers is to offer a range of sizes. Not only do hands come in quite a wide variety of shapes & sizes, but people like to hold a handle in different ways, I've discovered. The general shape of a bulbous end to sit in the palm, with a waist & thumb-stop seems to be generally acceptable to all, but different folks will like the relative sizes to be different, as well as overall size, no doubt. However, there is a limit to how much variety you could offer in a commercial situation, so some compromises will be necessary. I turned those handles for Brett to his specifications, and there are 5 sizes, which cover a very wide range. One of the middling sizes suits me nicely, for a rasp handle, the others are either too big or too small, though the smaller sizes suit me for files, which I hold a bit differently.

These curved rasps might be a bit limited in general application, but they are going to be a real boon when making closed saw handles, because of the curve & 'safe' side. Up til now I have used straight rasps to rough out my closed handles, and put up with the occasional catch on the wrong side, because I can fix that during the clean-up steps. It will be much easier to just hog away, with the curve keeping it well clear of the opposite side, and even if it does make contact with the wrong bit of wood, it isn't going to do any damage. I'll probably be more than happy with just two rasps, one coarse for roughing out & a finer one for getting the wood to the stage where a bit of cloth-backed paper & scrapers will quickly complete the picture. There are always those tight curves under the horn & at the inside bottom of the grip, but a small straight rasp can handle these well enough for me.

Looks like I might be demonstrating saw-making at this years' 'Hand Tool Event' here in Brisbane, & I certainly hope to own a pair of these rasps by then. It will be a good opportunity to show them off, & maybe attract a few more customers for Liogier rasps. Noel Liogier deserves full credit for his enthusiasm & cooperation in this project - customer service & personaal attention equal to Rob Lee's!

Cheers,IW

-

13th March 2012, 02:36 AM #6

Hi Brett

The perfect set means different things to different people.

As with all tools, one purchases what one needs ... although some purchase what they want. There is no "have to have these rasps" if you are making handles. I have been making saw and plane handles for yonks with straight rasps, files and sandpaper. Some may justify the expense of one rasp, others a couple (2 or 3)- rasps for making a few handles is something for the dedicated or passionate user. Obviously the more you make, the easier it is to justify the expense here.

There is no perfect number, I think, other than for those with deep pockets. I really do not believe that you can assume that cost is no object for most buyers.

So which is the most important rasp, if you could only have one? That is easier - I'd go with a 9 grain for rough shaping. If I had to get two, I'd go up the ladder to the 12 grain. Etc, etc. One can more easily turn to sandpaper after the shape is in.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

13th March 2012, 12:57 PM #7

-

15th March 2012, 01:21 AM #8

Senior Member

Senior Member

- Join Date

- Feb 2012

- Location

- Adelaide

- Posts

- 451

please excuse my ignorance, but is this a review of a prototype? because i've been looking through the Liogier site and only managed to find one curved rasp, but its grain is on the opposite side, for hollowing naturally, can you point me in the right direction to where these are located?

cheers

chippy

-

15th March 2012, 08:52 AM #9

Ch!ppy, you're excused, - they are indeed prototypes. You will have to wait another month or two before they appear on the website as a 'regular' item. They are going to a couple more people for evaluation before the 'production' models are settled on. If I get my digit extracted, you should see another opinion appended before the weekeend is over.

If you are in a hurry, and know exactly what you want, Liogiers will make a rasp to your specifications......

Cheers,IW

-

17th March 2012, 12:40 PM #10

-

17th March 2012, 02:06 PM #11

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

Wot Groggy said. Great work Ian.

FWIW in your shoes I would've done an oil finish cos these are going to be heirloom tools and oil will provide heirloom patina. Fairly quickly.

It's also worth asking whether ferrules are needed.

They make for a finished looking tool but may not be necessary. I don't use them on turning tools with a tang/shank of half inch or less, inc. bowl gouges which get some punishment.

Don't mean to quibble.Cheers, Ern

-

17th March 2012, 04:22 PM #12

Ern, there's no heirs looming around my tools

Btw the Copper Ferrules (?) were my request. I'm just about to fit some to my rasps delivered on Thursday, and the copper looks fabulous against the navy blue blade.

Edit: Reckon you're right about not needing a ferrule on the smaller rasps, but the tang on the 10"/12" is pretty wide unless you want to expose a lot of uncoated steel, and I always think they look better when the tang is almost all the way in the handle. I'll post a pic later on, but you'll need a cold spoon handy.

Cheers, Brett

-

17th March 2012, 04:55 PM #13

Yep - agreed, you can certainly get away without ferrules, but as Brett says, they were part of the order. They aren't a big deal to make & fit, and they may save possible embarrassment. I did warn Brett to make sure the hole for the tang is adequate, because some of the woods I used, like the She-oak, for e.g. can be VERY splitty if he is over-enthusiastic......

DAMHIK

As to the finish - pesonal choice, I guess. Oil is ok, but Shellawax is instantly 'dry', I like the sheen & feel it gives, and it is surprisingly durable.

Cheers,IW

-

17th March 2012, 05:18 PM #14

Hewer of wood

Hewer of wood

- Join Date

- Jan 2002

- Location

- Melbourne, Aus.

- Age

- 71

- Posts

- 12,746

Ferrules are usually brass, but can be copper (and Ian's set shows a mix), and I agree, they add a nice aesthetic touch to a handle.

I source them from Specialising in fine hand tools and wood working books - The Wood Works Book & Tool Co.

Do a search on 'ferrule'. Good range of sizes and the prices beat the competition.Cheers, Ern

-

17th March 2012, 05:50 PM #15

Have to agree about the sheen and feel of the Shellawax, the handles feel wonderful in the hand. I'll be back in a tick with that pic.....got the handles on (god they look good), but just have to fix a split...in the She-oak.....and a bulge.......

Similar Threads

-

LIOGIER RASPS have arrived - HOT DAMN!

By FenceFurniture in forum HAND TOOLS - UNPOWEREDReplies: 48Last Post: 4th May 2012, 10:47 AM -

SAW FILES - from LIOGIER

By FenceFurniture in forum HAND TOOLS - UNPOWEREDReplies: 3Last Post: 24th September 2011, 01:39 PM -

HEADS UP GROUP BUY – LIOGIER RASPS from France

By FenceFurniture in forum ANNOUNCEMENTSReplies: 0Last Post: 16th September 2011, 07:29 PM -

Rasps score

By Burnsy in forum HAND TOOLS - UNPOWEREDReplies: 2Last Post: 21st August 2007, 10:16 PM -

Rasps

By Harry II in forum HAND TOOLS - UNPOWEREDReplies: 34Last Post: 14th April 2007, 11:48 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote