Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 11 of 11

-

12th July 2020, 03:23 PM #1

Mixing tools between metric and imperial

Mixing tools between metric and imperial

I've been playing around building a saw till over the last few weeks and doing everything by hand. My tools are a mix of old and new, using a Stanley 71 Router and a Record 044 plough which have imperial cutters and my mortise chisels are metric Narex. So I find myself falling into these annoying situations where I set my marking gauge to the width of my cutter but then don't have the right size chisel to clean things up.

Anyone else had this problem? I want to buy a Veritas combination plane sometime soon and now I'm second guessing the metric cutters. Seems like it would be better to just standardise with one system for all my joinery stuff since they're a one time purchase.

Would be interested to hear people's thoughts, not so much about metric vs imperial but in using a combination of them for joinery or sticking with one system.

Edit: if it helps my Harold & Saxon bevel chisels are imperial too, I have a few metric ones for rough work but they're my go-to chisels.

-

12th July 2020 03:23 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

12th July 2020, 04:46 PM #2

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2007

- Location

- Victoria

- Posts

- 733

Sounds like you ought to go with imperial. Buying metric cutters for the combo plane later on isn’t the end of the world. Getting metric H&S chisels would be much harder and new imperial narex’s would be very simple.

You boys like Mexico ?

-

12th July 2020, 05:01 PM #3

I’m freely ambisinistrous between metric and imperial measurements; although I tend towards imperial for small stuff (<12”) and metric for larger (>300mm).

All of my planes are imperial but my chisels are a random mix of both or neither (eg marked 10mm but actually 9.7mm so neither 10mm nor 3/8”). I generally err towards imperial if both are available although sometimes I specifically need one or the other.Nothing succeeds like a budgie without a beak.

-

12th July 2020, 05:25 PM #4

regards from Alberta, Canada

regards from Alberta, Canada

ian

-

12th July 2020, 05:34 PM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2007

- Location

- Sydney

- Posts

- 749

Just use the chisel once size down for clean-up. Even with all imperial, the sizes are nominal anyway, so chances of a "perfect" match between cutter & chisel is a bit of a crap shoot. Recently made tools are usually pretty close to stated dimension, but I've certainly seen a fair bit of variation from nominal width with vintage stuff.

One advantage of having a "full set" of chisels is that its easier to find a close match. Metric sets often come in 3mm increments. Imperial in 1/8th inch increments.

-

12th July 2020, 07:05 PM #6

As you say, Ross, old chisels are only nominally sized, some of mine vary by more than a mm either side of what I think they're meant to be. Some of this variation represents manufacturing tolerance, and some have obviously been 'got at' in the past, for some special purpose or other.

Yep, I find my mix of both Imperial & Metric to be very convenient at times...

Cheers,IW

-

13th July 2020, 09:39 AM #7

After I posted last night, I was thinking about the chisel-size variation and how little it concerns me now, but I remembered that I used to find it frustrating early-on, & wondered why?

The answer is, I think, because I began my 'serious' woodworking as an adult with a house to renovate and furniture (mostly built-in) to supply for it. For many reasons I went for power tools (such as I could afford) which was ok for the sort of projects I was then attempting & my skill levels. As I progressed into 'finer' stuff, more hand tools came into the equation and it was this mix that caused me bother - chisels not matching the width of router bits etc. As I got better with the hand-tools, it became less fuss to do the whole job with them, rather than mixing them up with electron burners, and the 'problem' solved itself. The drift continued & over the last 20 years, it has come to the point where about the only one that gets switched on regularly these days is the tablesaw (edit: and the drill-press, nearly forgot about that!). By starting with hand-tools from the beginning of a project, you naturally fall back to the 'old ways' of sizing mortices, trenches, etc., off the chisels or other tools to be used & it becomes irrelevant in 99% of situations what the precise width of a chisel is once I've set my gauges to them.

However, if you use a mix of power & hand tools (as time & other factors dictate), such details as imprecise chisel widths can be a bother. There are workarounds, of course, but if you can find chisels that match standard bit sizes, it could certainly save some frustration...

Cheers,IW

-

15th July 2020, 02:55 PM #8

I started standardising on metric tools and fittings 25+ years ago, and tightened my tolerances 10 years ago; but it isn't easy. So many traps...

One of the usues is that when some manufacturers went metric they metricised the label but not the product. Thus a one inch chisel was rebadged as 25mm but the tooling didn't change so the nominal size remained at 25.4mm. Suppose you got a bonus 0.4mm of chisel.

An example: A while back I bought some Zenith brand rigging screws - also known as turnbuckles or bottle screws. They were clearly labelled at 8mm, but when I tried to get an 8mm thread to match that inside the rigging screws I found that all were too small. A mate said "That looks like Whitworth". Metric Whitworth - No. But imperial 5/16 inch Whtiworth threaded rod fitted perfectly.

In going metric, Zenith had simply rebadged their imperial product with a metric size, but had not changed their machining.

-

15th July 2020, 04:21 PM #9

Hi Dan

I grew up with both Imperial and Metric, so I guess that makes me bilingual

Most hand tools are in Imperial since the good stuff is either vintage British or vintage US, or new North American. As I recall, HNT Gordon is Imperial.

Inevitably, as we progress into hand tool work, tool slaving takes this a step further, with mortice chisels and plough plane blades being matched up. I would add router plane blades to this as well ....

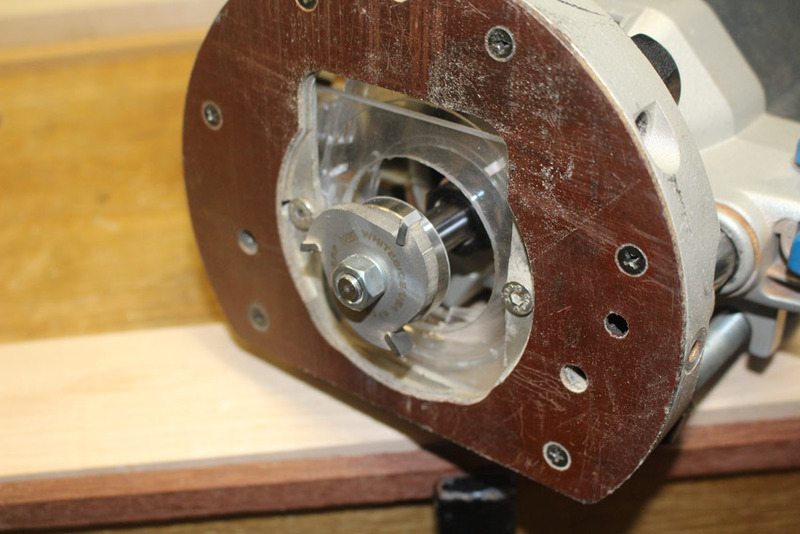

A few years ago I built a kitchen with US Curly Hard Maple (in Oz we refer to this as Rock Maple). About 20 frame-and-panel doors or so. These were made with a mix of power and hand tools. The grooves were added with a router slot-cutting bit (to create stopped grooves), and then finished with a mortice chisel:

A 1/4" grooving bit is used to route out the 1/4" deep groove for the panel ...

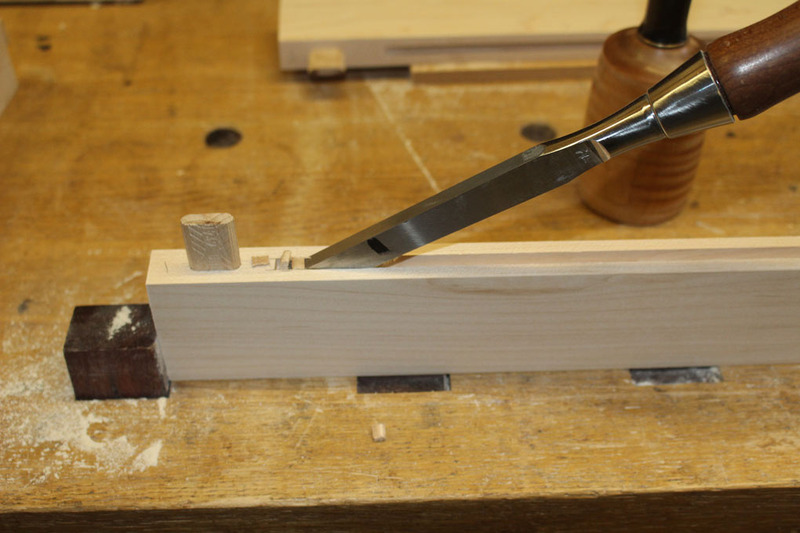

This leaves an uncut corner ...

The choice is to use a smaller bearing, which will cut deeper in the corner. I tried this on one door, however I found that the process of swapping the bearings out could cause the setting to change slightly.

Consequently, I decided to chop out the corners with a mortice chisel. This proved to be faster than setting up the router and re-routing the corners ...

It's been a few years, and the frames of a couple of the doors have come apart at the M&T join over this wet winter. The moisture in the air has swelled the panel, and this pushed the joint apart.

Over the past weekend I opened them up, and then there was the choice of planing down the panel to have more clearance, or deepening the groove. I opted to deepen the groove. To do this I used a Veritas Router Plane with a 1/4" bit. This worked very well. I used a larger (8mm) Domino this time, and all went back together, and looks as it was new.

The point to the above is that all these tools matched. They could be used interchangeably.

However ....

A turning point in my workshop in recent years was the purchase of a Hammer A3-31 jointer-thicknesser/planer. This is scaled in Metric and not Imperial. As a result, machining boards is easier if done in Metric than in Imperial. This also affects grooves, since it is easier to thickness panels to 6mm rather than 6.35mm (1/4”). And so there is a slow move to metric plough plane blades. Fortunately 1/8" = 3mm, and 5/16" = 8mm, so all I needed was a 6mm plough blade.

I can envisage that Metric will inevitably take over for all measurements. This is not the same thing as measuring for parts. Measuring for parts does not need a number; instead it is required to be a good proportion, aesthetic, sympathetic. You do not get these from Metric or Imperial numbers. You don’t even measure them. Instead you determine them by play. And you transfer them practically, with a story stick and cutting gauge.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th July 2020, 05:59 PM #10

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2007

- Location

- Sydney

- Posts

- 749

Well said.

There is an old adage:

"A house is built to the nearest inch; a machine is built to the nearest thou' and a boat is built to the nearest boat."

As for boats, the same is true for most furniture. The absolute measurement (in whatever system of units you might adhere to) is unimportant. What is important is as Derek noted above. The parts must be fit to each other - the initial planned measurements will unavoidably change as the build progresses.

However I do sympathise with the initial comment. Some tasks (but certainly not all) are made easier when cutters from one tool are the same width as those from another. The process when they don't is usually not too onerous.

-

19th July 2020, 10:05 PM #11

Thanks for all the comments everyone! Went with the imperial combination plane in the end and can always add metric cutters later. Turns out the metric cutters had a long wait anyway.

Similar Threads

-

Metric Vs Imperial

By Peter G in forum WOODWORK - GENERALReplies: 127Last Post: 9th June 2019, 11:11 PM -

Dado Set Metric or Imperial

By WillyInBris in forum TABLE SAWS & COMBINATIONSReplies: 18Last Post: 28th May 2019, 01:09 PM -

Imperial vs Metric bits

By Gerryattrick in forum ROUTING FORUMReplies: 15Last Post: 27th February 2015, 02:43 PM -

260 metric to imperial chart

By tanii51 in forum THE HERCUS AREAReplies: 3Last Post: 2nd June 2010, 02:50 PM -

Metric or Imperial?

By derekcohen in forum HAND TOOLS - UNPOWEREDReplies: 55Last Post: 24th May 2004, 04:34 PM

Reply With Quote

Reply With Quote