Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 46 to 60 of 77

-

1st December 2007, 01:14 AM #46

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Finland

- Posts

- 360

Hello fellas

,

,

Jake, first of all I wish your darling wife to get well soon .

.

2nd, oh yes you are helping, a lot. As a matter of fact, I do not recall I would have ever seen explanations of this level in any book, even in those ones considered as kinda cornerstones of this field of interest. Then again, my woodworking library is not the largest there is .

.

I think there seems to be a very simple operational principle behind it, almost too simple to get noticed. I wish I do not start to sound too scientific here, just practising my englishYes, there are plenty of factors that determine success with a plough. But if you took 2 blokes, each equally experienced, each with tuned planes ready to go, with the only difference being that one of them is using a flared blade.....and they had a race. I can tell you straight away, who will kick the other guys ???? both in terms of quality and speed.

I can tell you straight away, who will kick the other guys ???? both in terms of quality and speed.

.

.

Any edge moving and cutting any material, will form a stress field inside the cutted material ahead of the edge cut line. This stress field is located in a certain volume starting from the edge line, being at max right in front of the edge and decreasing gradually upwards, downwards and over edge corner sides, existing also a bit sidewards off the edge cutting route. In real edges like plane irons, there is also the blade face, against which the cutted chip will bang. This edge-induced stress field is essential and allowed.

Then, any surface just rubbing against any other surface causes similar kind of stress field. But now when the force is not consumed in cutting, it causes only friction. Because every material (including wood) is elastic, some more rigid material (like steel) presses the softer one (wood) a bit hollow.

In the case of square sided blade, where the cutting edge sharp corners will slightly wear off and get a very little bit rounder, the edge cut line is very slightly narrower than the actual full width of the iron. I takes then support from both walls of the groove like a saw blade without a set. I'd say, what will happen in any hands is that cutting stress field and frictional stress fields are summed up, causing much unnecessary resistance when planing the groove.

Moreover, during planing the groove, when the straight sided iron gets side support from the both groove walls, I would think that some green guy like me would constantly fail to produce squared groove. The reality is that if you are not able to tilt the plane back to the level with the wood to be planed, the groove does not appear as straight cornered (or straight line at all, despite the rigid fence).

The harder I think of it, more convinced I am that especially for a beginner, the most important feature would be laterally tapered (or flared, thanks for the new term to me) iron. With those you really could obtain control over plane levelness. I think it sounds logical, despite being a bit scientific, sorry .

.

The taper angle really don't need to be large but very acute, I'd say perhaps roughly according to the how a person would see (with a bare eye) the levelness of plane to the planed wood surface, or something like that. The blade narrowing would be not much of an issue, lets say if sharpening shortens the blade for 2 mm (lotsa sharpening) and side taper angle is like 5 deg per side (pretty much), the narrowing is roughly 0,35mm in total (0,175mm per side). Big deal for a woodworker .

.

Considering the groove side walls, there is a dedicated plane designs or scrapers for them, to widen and clean up the groove if wished. But more importantly, there really would be straight groove to fit tongue sticking out at straight angle.

I am still thinking of that little Veritas plane, looks very handy. On the other hand, old #45 looks just groovy .

.

kippis,

sumu

-

1st December 2007 01:14 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

1st December 2007, 02:44 AM #47

Jake and all

It has been apparent to me that we have two threads running concurrently, which is the reason why there are misunderstandings here.

The thread is first and foremost a review of the Veritas Small Plow plane. It began as an evaluation of three ploughs - their ergonomics, finish and performance. At the end of the day one wants to have a clearer idea whether or not the Veritas is worth purchasing, or whether one would be better served by finding a vntage #044 or #043 on the second hand market.

One question that needed to be answered is whether the Veritas could cut a satisfactory groove. The answer, as far as my own observations go, is that it does a fine job, as good as the #044 and #043. In fact, the performance of any one of these planes would satisfy most. The difference is that the Veritas is better built and easier and more reliable to use.

The question of whether the Veritas' blade design is as good as it gets, such as those grooves planed by Jake, is a separate issue. This is where the thread gets hot. In my mind there is no doubt that the Veritas performance is excellent, and that the performance of Jake's blade is also excellent - in fact it is better than excellent. But we are not reviewing Jake's blade design in this thread - it should have a thread of its own. Then the three designs - flare, trapezoid and parallel - can be compared and evaluated. I have said that I am interested in doing so. Jake your emotional investment in proving your blade design is destructive on the one hand (in highjacking this thread) but still remains a very important area for discussion. By following it through we will have a better idea of what we should look for and what we might do by way of modification to our plough blades. But this should not be in this thread (although it may now be too late to start again elsewhere).

In summary, this discussion detracted from the review of the Veritas because it focusses attention on one aspect of design and performance only, and it causes one to ignore the bigger picture.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

1st December 2007, 09:45 AM #48

Thankyou kindly Sumo. She is a darling. One of those strong people who always help others. Brave. Very proud of her. Unfortuneatly that means, she makes the worst patient !

..... She put off going to the hosipital too long. She'd shrugs off the pain, saying it would pass. 'Don't fuss Jake' I came in one day and found her staggering around in fever , still trying to clean the house

..... She put off going to the hosipital too long. She'd shrugs off the pain, saying it would pass. 'Don't fuss Jake' I came in one day and found her staggering around in fever , still trying to clean the house  Took her to the hosiptal to be told that she could have died.

Took her to the hosiptal to be told that she could have died.

But alls well now. Shes had her operation and home again. But how am I going to keep her in bed !.....She's gonna rip open her stitches trying to make cups of tea next or something like that for shore

That is something that definetly happens....its happened to me... it happens to everyone.....if the start of the groove doesn't start vertical enough.....and your say half way through the cut, its hard to recover from, because the off vertical cut you've already started is gonna keep you at that angle. There's no way to recover the cut.Moreover, during planing the groove, when the straight sided iron gets side support from the both groove walls, I would think that some green guy like me would constantly fail to produce squared groove. The reality is that if you are not able to tilt the plane back to the level with the wood to be planed, the groove does not appear as straight cornered (or straight line at all, despite the rigid fence).

It dithering sort of work. Slow, with substandard results.

You spend the whole time focused heavily to keep the plane as vertical as possible with resistance coming your way all the time. Its not free cutting.

Absolutely good for a beginner. Its good for everyone. Because an expert at ploughing is able to take faster and cleaner cuts as well.The harder I think of it, more convinced I am that especially for a beginner, the most important feature would be laterally tapered (or flared, thanks for the new term to me) iron. With those you really could obtain control over plane levelness. I think it sounds logical, despite being a bit scientific, sorry .

.

No it needent be big. But IMO, better to have it than not.The taper angle really don't need to be large but very acute, I'd say perhaps roughly according to the how a person would see (with a bare eye) the levelness of plane to the planed wood surface, or something like that. The blade narrowing would be not much of an issue, lets say if sharpening shortens the blade for 2 mm (lotsa sharpening) and side taper angle is like 5 deg per side (pretty much), the narrowing is roughly 0,35mm in total (0,175mm per side). Big deal for a woodworker .

.

As long as you can see it by eye when its all lined up in the skate. i.e that the blade tapers off both sides, to ensure that the width of the groove your cutting will always be larger than the blades shank, so that plane can accomidate for human movement (uno rolling the plane over back and forth slightly). thats it. simple. The principle holds true for any plane thats cutting a shoulder.

The only resistance you want the plane to feel is from the actual cutting of the timber....don't want any risk of blade or skate rub off the shoulders.

It more accomidating too. You don't have to get anal with setting up fences perfectly parallel as well. Much faster setup.

These tools arn't powered machines. They do not handle resistances like these well at all. Yet its too time consuming to try and minimize them with a normal untapered blade in its groove. You have to elliminate every unnecessary resistance to make them practical. Tapering these blades knocks a lot of these resistances on the head. If you don't address them your just a dithering along with substandard results.

-

1st December 2007, 09:53 AM #49

Derek.... There's really only one issue to be concerned with.

Getting your plough to work as well as possible. Really the rest is just crap. Hangups etc etc. Bullshyt.

I have given you something that will help that issue. And you don't want it for one reason or another.

Your grooves can be improved on greatly, as are mine with a substandard setup. Pride or whatever has you even failing to admit that.

Where can I go from here ? Do you want me to show you some more pictures ?.......How about a wide plough cut, a long distance off the fence. There the hardest ones. But can be done quite cleanly, due to flared blades.

Sorry, I imagine you don't want to see that.

I imagine you don't want to see that.

If you like your veritas plane thats great. But fancy handle, grip, colour, pictures, mean sweet bugger all don't you think ?

-

1st December 2007, 11:30 AM #50

Thread edited by moderator

Thread edited by moderator

This thread has been created from pieces of a discussion on Derek Cohen's review of the Veritas Plow Plane. The thread turned into a discussion of the merits of using a blade with a taper, which applies to ALL plow planes, and deserved a thread of its own - which is why this thread has been created. This thread picks up from post #18 in the other thread.

This thread should focus on comments or observations of the effectiveness of tapered blades in plow planes generally.

-

2nd December 2007, 10:08 AM #51

No response again....ok. Maybe you need more evidence.

I'll keep throwing pictures up. I'll have to refer to previous photos at the moment. I'll try and get to the shed when I can. I can think of a couple more things I could take photos of to try and clearify even more.

I don't know why I need to though You guys ARE the experts. You must know all of this already

You guys ARE the experts. You must know all of this already Thousands of dollars was spent in designing that veritas plough ? You'd know better than me for shore. Reviews are done and pretty pictures shown, and a tone of complete wisdom in your paragraphs.....I'm just a joiner. How the ???? would I know. And I'm only the 1% too eh Derek

Thousands of dollars was spent in designing that veritas plough ? You'd know better than me for shore. Reviews are done and pretty pictures shown, and a tone of complete wisdom in your paragraphs.....I'm just a joiner. How the ???? would I know. And I'm only the 1% too eh Derek

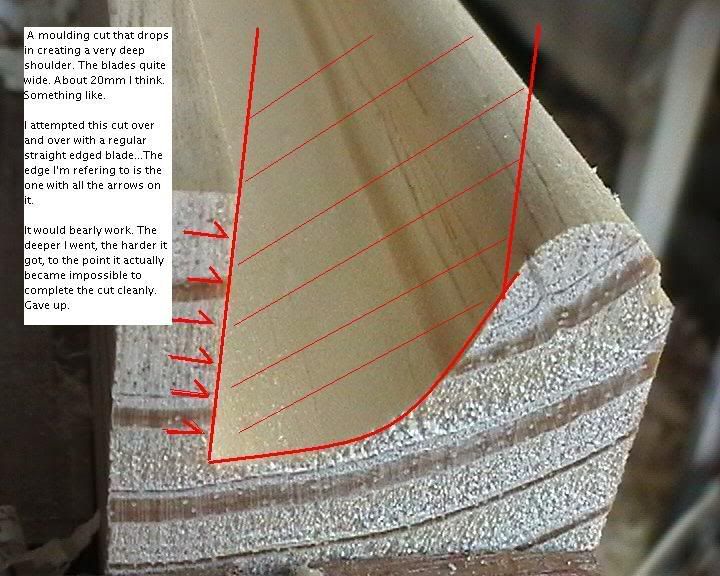

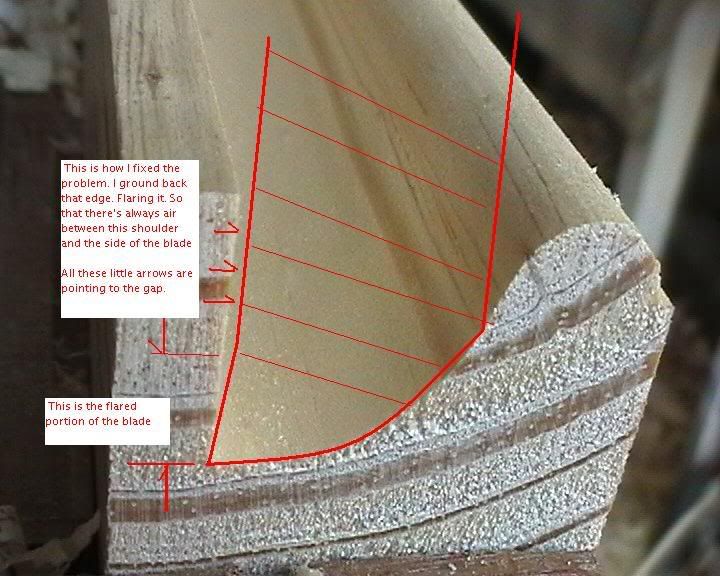

I took this photo from a previous thread of mine.

http://www.woodworkforums.ubeaut.com...icture+framing

Yes, I know its on moulding planes. Not ploughs. But the same issue is there as well. ie. Resistance to planing from shoulder rub off.

I've chosen this particular photo because it cuts a particularily deep shoulder. A lot of resistance along that edge.

As soon as I flared it, the plane freed up and I could easily depth out.

I can get a picture of the blade for you if you like.

You wouldn't bother even attempting that cut without a flared blade. Futile. After trialing it yourself, you would be an absolute fool to not see the improvement. Just as you would be if you had trialled flaring plough blades and not see an improvement.

So, are you getting it yet ? ...... flared blades free up the cut so much it allows you to go very deep as well.

Now, why hasn't veritas, being the innovative company they are, and with the expertese they apparently have, haven't provided flared blades in their set ? ...

Next time I get to the shed I'll do a series of plough cuts with a 1/4" flared blade (same width as the one you used in that veritas isn't it Derek ?). Maybe you could try the same and compare Derek. I'll use a #44.

Can you see yet why I've formed the opinion that $300 on this veritas plough is absurd ?

-

2nd December 2007, 01:57 PM #52

Patience Jake.

For one thing, I don't have spare blades to regrind. I will have to make them, and I still have to obtain the steel for this. It will likely take a couple of weeks. I have other projects on the go that have greater priority.

Another point is that I do not doubt that the flared blade will work. I have said so before, but I think that you have missed the point of my postings. It is not whether it works, but whether it is either best or necessary.

"Not best!" I can just hear you exclaim in frustration ... "I'd better post another picture .. quickly!!". "Derek, haven't you seen enough to be convinced!!!!"

Again, it is not that I do not see it working, and working most excellently at that, but whether it is the best in the circumstances. What circumstances, you ask? (Well you didn't, so I have taken the liberty of asking on your behalf ).

).

The first is in regard to Tool Slaving. This is the term given to sizing all linked tools so that they integrate their functions. Someone wrote earlier that you just size the drawer insert to the size of the groove (rather than vice versa). This would be an example of the absence of tool slaving. A good example of tool slaving is when your mortice chisel is the same size (width) as that of the router plane blade and the plough plane blade, all of which are used to create (say) a floating panel. Yes it is possible to tweak edges to fit, but some cabinetmakers will not want to do so. Since a flared blade will alter width as it is sharpened, it is difficult to see it as part of a tool slaved team.

The second objection is whether a trapezoid shape is preferred. Both have pros and cons. The advantage of the trapezoid shape is that it retains the blade width while still reducing the contact (= friction) with the side wall. The issue of friction, or binding, is what was raised in the last thread. As Mike noted, the amount of friction occurs in proportion to that size of the blade. Actually, I would consider that it occurs in proportion to the depth of the cut is association with the width of the blade, with a wider blade having less stability to resist "catching" a wall. So a thicker parallel sided blade would likely be less vulnerable than a thinner parallel sided blade (a lot like the blades on Stanley bench planes). The question is, "at what point is the thickness of the blade capable, if at all, of overcoming issues of friction?". The Veritas plough blades are certainly thicker than those of a Stanley or Record. But you should see some of my woodies!

In association with #2, the question is whether the side wall is important in maintaining a line, that is, whether it helps in addition to the fence. Yes, I understand that the advantage of the flared blade is that it has the ability to be adjusted, unlike a blade that is "locked" in a groove.

Actually, in my experience, the groove walls do not lock in a blade, even a parallel-sided one. There is still a bit of tilt possible, probably because the wood has some flex. And this leads to the third point ...

Number three is about "what is good enough and what is overkill". The fact is that I can produce very acceptable grooves with a wide variety of ploughs that I have at my disposal - I have many! ... in addition to the Veritas, I have a #043, #044, #45, #46 and several woodies. Their blades vary from trapezoid to parallel to tapered. They all work well, and I have used them successfulkly for drawers in the past. Good grief, I have successfully used a chisel and a router plane (only) in at least two or three articles. These grooves were rougher than those produced by a plough plane, but still perfectly satisfactory. Factors such as tearout (which, incidentally, was never a feature of any of the grooves I ploughed) are totally irrelevant since they would not be seen in this hidden joint. The examples of the square walls you ploughed were fantastic ... really ... but not really that different from the results I achieve with more traditional blades.

When I stated "the jury is out" I was not referring to whether I was in doubt as to the effectiveness of the flared design, but rather whether this is the best way to go after considering the whole. You appear to find this hard to focus on - understandably, as your energy has been in creating as clean a groove as possible. But I am equally involved with the whole experience, which includes how the plough plane works from the mindset of a novice, through to the tool slaving ideal of the expert.

I will try to push thinks on to get to this. In the meantime others may wish to do so and report back.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

2nd December 2007, 04:02 PM #53

Yes dad. I use hand planes mate. I am patient. You don't respond. And you repeat questions that I've already answered. I've been at a loss to see how we can have that constructive converstation (you mentioned that) if you don't even respond to my answers......(it gets constructive then uno)

Another point is that I do not doubt that the flared blade will work. I have said so before, but I think that you have missed the point of my postings. It is not whether it works, but whether it is either best or necessary.

"Not best!" I can just hear you exclaim in frustration ... "I'd better post another picture .. quickly!!". "Derek, haven't you seen enough to be convinced!!!!" Well, if you were in my shoes and Mike critized your ideas without trial repeatively, and I was in your shoes denying completely that my grooves were substandard with little response, when the whole bloody world seeing that they are...what do you expect. . uno ,there wouldn't be one professional woodworker out there that would accept your grooves as excellent (as you say they are). And I don't think any hobbyist should ever aspire to them either. Yet, its hard to deny that this is exactly the sort of results that veritas plane is going to yeld with blades like that.

Well, if you were in my shoes and Mike critized your ideas without trial repeatively, and I was in your shoes denying completely that my grooves were substandard with little response, when the whole bloody world seeing that they are...what do you expect. . uno ,there wouldn't be one professional woodworker out there that would accept your grooves as excellent (as you say they are). And I don't think any hobbyist should ever aspire to them either. Yet, its hard to deny that this is exactly the sort of results that veritas plane is going to yeld with blades like that.

Again, it is not that I do not see it working, and working most excellently at that, but whether it is the best in the circumstances. What circumstances, you ask? (Well you didn't, so I have taken the liberty of asking on your behalf ).

).

I just think you just need more experience at ploughing Derek with flared blades.

I just think you just need more experience at ploughing Derek with flared blades.

I know what tool slaving means.The first is in regard to Tool Slaving. This is the term given to sizing all linked tools so that they integrate their functions. Someone wrote earlier that you just size the drawer insert to the size of the groove (rather than vice versa). This would be an example of the absence of tool slaving. A good example of tool slaving is when your mortice chisel is the same size (width) as that of the router plane blade and the plough plane blade, all of which are used to create (say) a floating panel. Yes it is possible to tweak edges to fit, but some cabinetmakers will not want to do so. Since a flared blade will alter width as it is sharpened, it is difficult to see it as part of a tool slaved team. Why do you feel the need to describe it to me ?....I work with cabinetmakers for a living. In a joinery. Uno, a real one.

Why do you feel the need to describe it to me ?....I work with cabinetmakers for a living. In a joinery. Uno, a real one.

What will you fit to a groove made by a plane Derek ? If its a floating panel what tool MUST you own, sharpened to matche this plough width ?

If you insist on doing it all by hand, then after thicknessing the panel, you'd raise it. The depth of the meeting tongue is dictated by the depth stop of your plane, or router or whatever your using...you have to set it anyway.

Hand tool Slaving is a weak point in reality. In reality uno what a cabinetmaker would do to cut a groove 9 times out of 10?......power.......He'd use a router with straight bit or a slot cutter....or through a tablesaw. Theres the fixed width cut. Its what I do all day.

I know all about slaving.....mortising machine, tenon machine...face down There set to match. etc etc But most things that are fitted to grooves like these are tongue like shapes that are thicknessed without a matching tool needed.

The only exception that I mentioned before (you must have overlooked that post as well ) is when your fitting glass or acrylic....or I suppose...if your into shyt, like ply or mdf etc. If its solid, no problems.

) is when your fitting glass or acrylic....or I suppose...if your into shyt, like ply or mdf etc. If its solid, no problems.

Traditional plough work is way too slow and the results are ...well uno. Doesn't matter how brilliant one thinks they are at pushing a plane.

But if you flare the blades..... ..... whats this ....this can't be happening Mike !......no, no. Lets pretend its not happening. Its against all the rules

..... whats this ....this can't be happening Mike !......no, no. Lets pretend its not happening. Its against all the rules

yes I know. Most of plough blades have that. But still its no where near the improvements you get with flaring it along its length like I've been saying where none of it ever touches the wall.. Your still getting rubb off.....still getting resistance, which influences everything......and if that edge is also sharp, and some of it will be, when you lean her over a touch you know what that sharp edge is going to do to that shoulder eh ? This is not rocket science. Your risking a mess and time lost. For christ sake I hope we can cover that up !The second objection is whether a trapezoid shape is preferred. Both have pros and cons. The advantage of the trapezoid shape is that it retains the blade width while still reducing the contact (= friction) with the side wall. The issue of friction, or binding, is what was raised in the last thread. As Mike noted, the amount of friction occurs in proportion to that size of the blade. Actually, I would consider that it occurs in proportion to the depth of the cut is association with the width of the blade, with a wider blade having less stability to resist "catching" a wall. So a thicker parallel sided blade would likely be less vulnerable than a thinner parallel sided blade (a lot like the blades on Stanley bench planes). The question is, "at what point is the thickness of the blade capable, if at all, of overcoming issues of friction?". The Veritas plough blades are certainly thicker than those of a Stanley or Record. But you should see some of my woodies!

That trapezoidal shape is not necessary. Only thing you need to ensure is that the blade is a touch trapezoidal right at the edge (else it won't cut at that point. And your'll notice something is wrong with your plane. Some kind of resistance. And you start scratching your head wondering why. )

Maybe if it releases that way. Wood releases in all different ways when its cut. Some of that freedom you mentioned is probably because you've just bruised the groove because your human(some of that would have been going on in those 'excellent' grooves you cut). Sometimes I've noticed timber realeases the other other way and actually closes up the groove enough that you jam up. What do you do then ? .....(flaaaaaaarrrrrred bladesActually, in my experience, the groove walls do not lock in a blade, even a parallel-sided one. There is still a bit of tilt possible, probably because the wood has some flex. And this leads to the third point ... ) Or do you just rely on that mostly dull trapezoidal edge....and just blast it through baby !...she'll be right......ooooooh that leaves a lovely finish.

) Or do you just rely on that mostly dull trapezoidal edge....and just blast it through baby !...she'll be right......ooooooh that leaves a lovely finish.

Well like I said before........just quitelyNumber three is about "what is good enough and what is overkill". The fact is that I can produce very acceptable grooves with a wide variety of ploughs that I have at my disposal - I have many! ... in addition to the Veritas, I have a #043, #044, #45, #46 and several woodies. Their blades vary from trapezoid to parallel to tapered. They all work well, and I have used them successfulkly for drawers in the past. Good grief, I have successfully used a chisel and a router plane (only) in at least two or three articles. These grooves were rougher than those produced by a plough plane, but still perfectly satisfactory. Factors such as tearout (which, incidentally, was never a feature of any of the grooves I ploughed) are totally irrelevant since they would not be seen in this hidden joint. The examples of the square walls you ploughed were fantastic ... really ... but not really that different from the results I achieve with more traditional blades. .......I don't think the rest of the world would think your excellent is that excellent. Sorry. I get those kind of results too with traditional setups too if thats any concelation. And I'm a little bothered by the fact you don't see that. Mentioning parallux error etc.

.......I don't think the rest of the world would think your excellent is that excellent. Sorry. I get those kind of results too with traditional setups too if thats any concelation. And I'm a little bothered by the fact you don't see that. Mentioning parallux error etc.

I would recommend them to actually buy a old plough or a trimmer over buying the veritas. Sorry. Its just that obvious. Spend the savings on another tool. or wood. or whatever.

I've spent hours as well, setting these things up. Very stubborn. Looking at every detail. And its no wonder the worlds been taken over by routers.

But I love planing profiles. The only time I started enjoying them though, is when I started releasing the unrealistic tolerances the designers put on them(by flaring them). Let them move more. And it became apparent how practical they can be. A whole new world of planing opens up.

You know all about the reputation of stanley combination planes. Boat anchors and all that. This is the main reason why they have this rep.

Well whatever. I'm a broken record here. Had enough for today. My eyes are sore.When I stated "the jury is out" I was not referring to whether I was in doubt as to the effectiveness of the flared design, but rather whether this is the best way to go after considering the whole. You appear to find this hard to focus on - understandably, as your energy has been in creating as clean a groove as possible. But I am equally involved with the whole experience, which includes how the plough plane works from the mindset of a novice, through to the tool slaving ideal of the expert.

I will try to push thinks on to get to this. In the meantime others may wish to do so and report back.

-

2nd December 2007, 09:35 PM #54

Senior Member

Senior Member

- Join Date

- Sep 2006

- Location

- Bookham, Surrey, UK

- Age

- 79

- Posts

- 137

Hi Jake,

I just wanted to say a few words in support of what you have been saying

I've used metal plough and combination planes since 1970. In the early days I struggled, like most, to get them to work well. Over the years I've read mountains of material but most of it was little more that what manufacturers supplied in their instruction sheets or stuff that, in effect, said you could never get them to work well, so use a router instead.

In fact, it wasn't until I started reading your stuff that I fully understood all the things that were wrong and how to put them right. Since adopting some of your methods I've really started to enjoy using my planes and to get the best from them. How others have difficulty with the logic of what you say is difficult to understand - that's if they have tried the things you suggest.

Whether it's necessary or worth the effort is, of course, for individual users to decide. It all depends on how far they want to go to achieve the best results.

Whether manufacturers will ever supply plough and combination planes with flared blades or some of the other modifications you suggest is doubtful in my view. It all comes down to cost - and they are the sort of modifications individual users can make for themselves if they wish. But it's good that you, alone, have showed them how to do it

I, for one, will always be grateful for what I have learnt from you about how to make these planes work well.

Cheers

Paul

-

3rd December 2007, 08:23 AM #55

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Finland

- Posts

- 360

Hello,

Likewise, hereabouts. Generally, there seems to be insight available only in different forms of personal opinions of end users, but not as actual documentation as factory recommendations. On the other hand, it is kinda understandable when the major operative interface is human being and his ability to understand. I can imagine how large the consumer service department would have been, only for answering calls questioning about this and that detail in extremely intensively written manual.

I have a funny feeling that during the era when these planes were in extensive use, better craftsmen were aware of these details. If so, those details have obviously been completely hibernating for awhile, making Jake's plough iron design principle essentially his original conclusion. It is so, that an idea is born at first in one mind, despite that there would be minds thinking in a similar way through all eras, all around the world.

Whether it's necessary or worth the effort is, of course, for individual users to decide. It all depends on how far they want to go to achieve the best results.

There would perhaps be found some evidence of earlier applications on this if dug up, assuming that plough irons undergone this modification are not all used up because of their functionality.

I want to see that little Veritas to be successful. Of brand new planes, it is at the moment only of it's kind when considering it's obvious quality in it's make. It will be also well defended if it can be tuned up into a major player with a just minor modification of it's consumables.

Whether manufacturers will ever supply plough and combination planes with flared blades or some of the other modifications you suggest is doubtful in my view. It all comes down to cost - and they are the sort of modifications individual users can make for themselves if they wish. But it's good that you, alone, have showed them how to do it

The other reason is that it is a product of a house of quality tool products. Currently, there is a plethora of one-man enterprises producing high quality tools and accessories. The trouble is that when the man behind the production leaves the business, the fluent use of manufacturing database is gone, too. When the man has left the building, there is unfortunately a minor possibility that some other person would take care of the business and continue the style and make just like that.

An entire tool production house is in a different position. It can take some drawbacks (which is actually not shown out with this Small Veritas Plow Plane when considering the actual plane frame and other components) better because the other lines of products are still trusty and highly appreciated. Despite men are changing, a tool house is able to maintain database in full use over generations of workers much better than small enterprises. Not so much relying on one person only, I would believe.

In it's time, Stanley Works was in many occasions at firing line because of flops, so has been the case with the other major companies, too. It's inevitable, and in a way, also acceptable because it excites evolution into better products.

The third reason is the concept of hand tool itself. I bought my first power router about 15 years ago, and I remember how excited I was after the first successful moulding. My reaction was like: "Yee-haw, it's precisely like in furniture store". Some years passed by, and it turned out to be like "Damn, it's exactly like in furniture store". (I recall have actually read these lines somewhere. But I really can't say I'm actually quoting somebody here because this was how I felt.)

My hand tools have interacted with the wood completely differently, leaving every time personal cut print and shape, highlighting the wood and making me feel good.

kippis,

sumu

-

3rd December 2007, 07:40 PM #56

Thanks Fellas. Maybe 3..or even .4 % now Derek. Crrrrrreeeeeeeeping up slowly .

Thanks Paul. That really means a lot to me. I put so much effort into trying to be clear. Always fear thats where I may go astray.

Absolutely !.....right with you. If people are happy with what they got thats fine.Whether it's necessary or worth the effort is, of course, for individual users to decide. It all depends on how far they want to go to achieve the best results.

Personally, there'd be plenty of stuff I do that some would think is inadequate. But this is what I don't get about others. Certainly stirrs me on when they can't admit. I don't have any problem with saying 'yours is better than mine' . I'm actually quite a cluts. Conceeded to that a long time ago.

I agree. I think its particularily doubtful because seemly most of those who are into hand planes aren't flexible enough to give it a go. (But Dereks giving it a go. Geeeez its gonna be hard for you Derek to stay objective on this oneWhether manufacturers will ever supply plough and combination planes with flared blades or some of the other modifications you suggest is doubtful in my view. It all comes down to cost - and they are the sort of modifications individual users can make for themselves if they wish. But it's good that you, alone, have showed them how to do it

)

)

Thanks Paul. [/quote]

-

3rd December 2007, 08:06 PM #57

For shore. Just ask Mike....Been done before hasn't it mate ? ...

But I don't think it really matters whose done it. Just as long as improvements arn't forgotten. Or buried by stubborn traditionalists.

and people will always try to get others to drop excessive dollars on tools un-necessarily as well I suppose.

I don't know. Mike might know. He's tried everything else. He knows all about ploughs and dovetail planes to the nth degree. Doesn't even have to try them first....he just knnnnnnooooooooowsThere would perhaps be found some evidence of earlier applications on this if dug up, assuming that plough irons undergone this modification are not all used up because of their functionality. clever stuff that.

clever stuff that.

I agree. It be great for them to be successful. And I'm sure it will be because of their name alone. Spose I'm not helping. But I'm not on their payroll, and I like to be honest.I want to see that little Veritas to be successful. Of brand new planes, it is at the moment only of it's kind when considering it's obvious quality in it's make. It will be also well defended if it can be tuned up into a major player with a just minor modification of it's consumables.

My hand tools have interacted with the wood completely differently, leaving every time personal cut print and shape, highlighting the wood and making me feel good. yes. Thats why I like them too. Gota justify their use though. IMO it will become a dust gathera pretty soon if it doesn't work well enough.

yes. Thats why I like them too. Gota justify their use though. IMO it will become a dust gathera pretty soon if it doesn't work well enough.

Sorry Sumo. I'm being very sarcastic. ....

....

-

3rd December 2007, 08:42 PM #58

Senior Member

Senior Member

- Join Date

- Sep 2006

- Location

- Bookham, Surrey, UK

- Age

- 79

- Posts

- 137

-

3rd December 2007, 11:54 PM #59

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Finland

- Posts

- 360

Hello

,

,

You like this, admit it

You like this, admit it  . Yes, as a fellow crusader for my own thoughts applied elsewhere, there tends to appear occasional funny feelings inside time to time. I know, it's the credibility what a honest man always worries to lose. Well, time goes by and suddenly here and there starts to pop up talk about things strangely closely related to the subject. A fellow crusader is sensitive to such talk, yes, but in such topics both utilizing laws of nature and also involving human interface, there is too much to left unnoticed in related discussions.

. Yes, as a fellow crusader for my own thoughts applied elsewhere, there tends to appear occasional funny feelings inside time to time. I know, it's the credibility what a honest man always worries to lose. Well, time goes by and suddenly here and there starts to pop up talk about things strangely closely related to the subject. A fellow crusader is sensitive to such talk, yes, but in such topics both utilizing laws of nature and also involving human interface, there is too much to left unnoticed in related discussions.

I have only two oldish woodie plow planes both needing serious reconditioning before tryout. One of them has 4,1 mm wide iron, and the other merely 3,2 mm wide iron. I believe they were designated for making grooves for drawers or trays to fit plywood bottoms.

I wish to receive an offer on one german made old woodie I have looked at hereabouts. The current owner does not use it but is hesitating to sell it. There would be a set of more beefy irons included, too.

I wonder, because some guys like Derek were worried about losing the original iron width and therefore breaking the chain of tool slaving, how about then starting the taper after 1...3 mm distance from the edge? It will lower the friction as well, and maybe also would provide the possibility of re-levelling the plane if suddenly tilted during planing. Then again, 1-2 deg taper should be easy to make with just a minor grinding.

2mm of blade wear because of sharpening and 1 deg of taper per side will make roughly 0,07 mm of total reduction in edge width, 2 deg will make 0,14mm and so on, in 0,07 mm steps per degree.

For 3mm of wear length, the total reduction step will be 0,105 mm per degree, roughly.

I understand the concept of tool slaving. It is called with other names in CNC machining industry and such manufacturing businesses where time is money and unnecessary tool wear is therefore almost heresy. Essentially it is optimization, where time and cost factors are crucial without compromises in manufacturing precision. It indeed means supporting of huge amount of somehow well documented tools and bits in reserve.

kippis,

sumu

-

4th December 2007, 05:59 PM #60

Retired

Retired

- Join Date

- May 1999

- Location

- Tooradin,Victoria,Australia

- Age

- 73

- Posts

- 11,918

Keep it civil kiddies. Sarcasm is unwarranted.

Similar Threads

-

Homemade Plane Blades from M2 HSS for Wooden Planes

By thumbsucker in forum HAND TOOLS - UNPOWEREDReplies: 351Last Post: 27th July 2009, 04:52 PM -

D2 Plane Blades - Batch Order 02

By thumbsucker in forum HAND TOOLS - UNPOWEREDReplies: 259Last Post: 16th November 2008, 08:34 PM -

removing stuck blades from old planes

By bannock in forum JAPANESE HAND TOOLSReplies: 13Last Post: 31st January 2008, 04:29 PM -

The Veritas Small Plow Plane

By derekcohen in forum HAND TOOLS - UNPOWEREDReplies: 18Last Post: 1st December 2007, 11:30 AM -

Putting wooden plane blades in Stanleys.

By JDarvall in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 18Last Post: 30th November 2005, 08:29 AM

Likes:

Likes: