Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 15

Thread: Raising a panel with a 45.

-

20th January 2007, 04:38 PM #1

Raising a panel with a 45.

Raising a panel with a 45.

Hello,

Share something I've learn't of late. An idea to build on maybe....A way of raising panels with a stanley 45. Probably more appealing than my earlier idea using a stanley 55.

I'll try and show you what I mean with this series of pictures. here's the panel I cut with the 45.

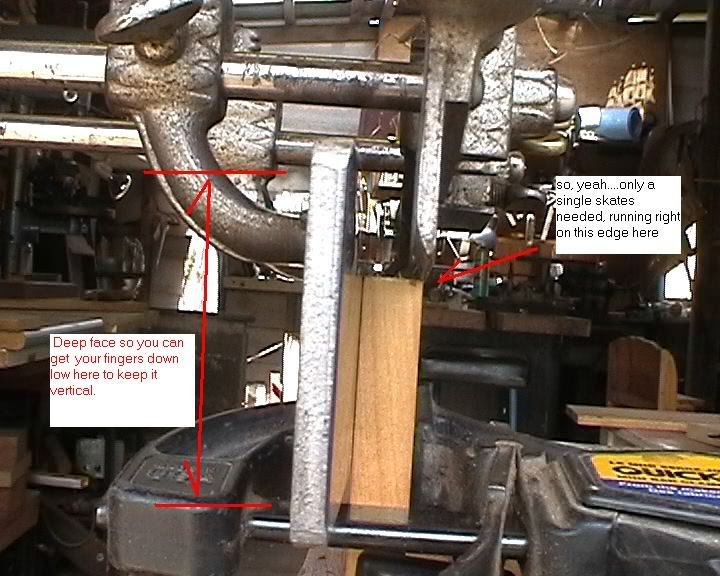

Its possible if you setup the tool this way.....that is

- Just the single skate, but positioned offset on the other edge.

- remove the other sliding skate all together.

- add a deep face to your fence. Much easier to keep the thing vertical with more leverage.

Found it to be a very stable setup. Thankfully too, because you'll need it to be when cutting down into end grain..... ..the blade naturally draws the fence in tight.

But, with this setup you don't have a depth stop.....so you'll have to plane to lines....marking guage here scribing them in advance.

setup fence

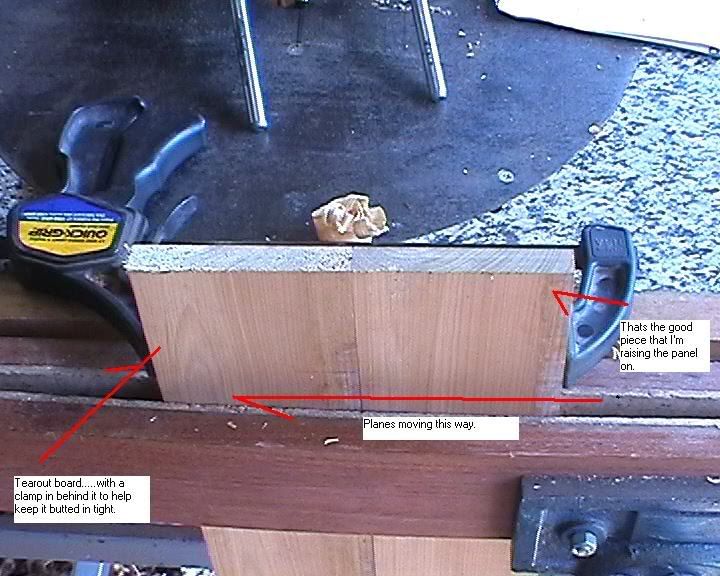

I'd tackle the end grain first...so that the 'with' grain cuts latter will clean it up nicely.

Will need a tearout board though of some kind.......all I've done here is clamped up a bit of scrap of the same thickness to take the tearout.

Rip into it.

One end grain cuts done. Do the other side.

Hard part over. Now with both end grain cuts complete, can do the with grain cuts....just do both sides and its done.

I like the idea of using these raised panels for drawer bottoms too. Will try use myself when I get the chance.

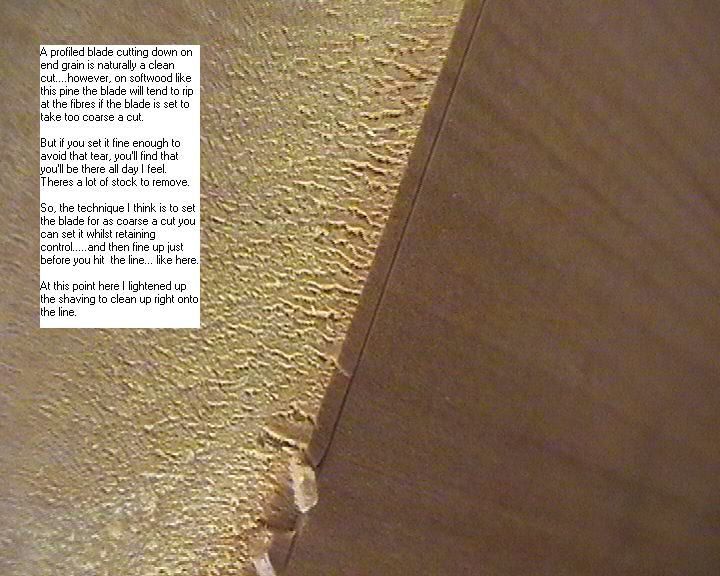

the blades nothing special.

Can also do it with a stanley 55 or other ploughs.....but the 45 or 55 I've found to be best suited since the skates are higher and cut deeper into your timber as needed to cut the wider profiles as you may do for raising panels etc. .

Hope some of that be of some use. Have a good weekend.

-

20th January 2007 04:38 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

20th January 2007, 05:19 PM #2

Jake

That really is going to the darkside but that is excellent application of old equipment.

-

20th January 2007, 05:28 PM #3

A lot of time and effort to posting a successful outcome with good old handtools - welldone.

Apart from the pleasure of using good old world techniques with some inginuity is this method in your opinion worthwhile for making a whole kitchen or wall unit?Cheers

TEEJAY

There is a very fine line between "hobby" and "mental illness"

(Man was born to hunt and kill)

-

20th January 2007, 05:42 PM #4

Jake

That is superb!

I do struggle to make some sense of the pictures - but then I have spatial difficulties at times - however there is no denying those results, and the picture of the blade makes it easier to comprehend.

How about a "Tutorial for Dummies", "Tutorial for Derek" - same thing!

Well done!

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

20th January 2007, 07:25 PM #5

%$@#^$#%$!!!

Nothing much else to say really.

I reckon I could coax my 044 to do that too, when it gets here...

What about a depth stop between the body and the fence or the depth stop on the fence itself? Not really needed by the look of it, but would make it a tad easier to avoid mistakes.

-

20th January 2007, 07:54 PM #6

.

.

- Join Date

- Jul 2005

- Location

- Victoria

- Posts

- 5,215

Great stuff Jake

You are the forums real Darkside King. Refreshing to see some darkside stuff actualy being done instead of the ones who just keep prattling on about how sharp and shiny their tools are. Keep it up

You are the forums real Darkside King. Refreshing to see some darkside stuff actualy being done instead of the ones who just keep prattling on about how sharp and shiny their tools are. Keep it up

-

20th January 2007, 08:09 PM #7

Thanks Barry. Nice of you to say.

Ta Teejay.

ummmmm .... I don't really know to be honest...lot of factors. Probably same old story really. If you've got a lot to do, a router table be better.....

.... I don't really know to be honest...lot of factors. Probably same old story really. If you've got a lot to do, a router table be better.....

You can speed up the process by doing the end grain cuts of many panels at once.....uno, just clamp up a few all together in a line with just a single tearout board.

Derek: Thanks.....No, its probably my pictures that confuse. Sorry. A lot of the posts I've revisited from the past don't make sense. I'm trying though. Just doesn't come naturally I think.

Schtoo:

You can use that 44 the same way.....but, you won't be able to make very deep profiles with it, cause the skates aren't as deep....see the left side (I mean the side without the depth stop) of the 45's are very deep... you can go as deep as the fence rods.

Something that may help..... you'd probably know why it happens.... but the blades that often come with the 44 are named 'tungsten steel'...and there hard wearing but brittle......Found I've had to keep the bevel angle above 30 degrees or else the blade edge tends to fail (little chips,,,,and consequent lines left on the timber).

Yep....your right about the depth stop. Thats exactly what went through my mind.....and thats what I've done to another of my 45's....I've added a lefthand depth stop....and its works brilliantly......its the basis of my hand plane idea I've been going on about (giving it away now ....doesn't matter. Rob lee couldn't take it, and I've had enough thinking about it)

....doesn't matter. Rob lee couldn't take it, and I've had enough thinking about it)

With a flat bottomed skate (like your record 44), left hand depth stop you have a plane that makes the most accurate of cuts I've ever seen (because of the stable characteristics of working off an edge)......so you can cut sash profiles...etc....perfectly square rebates.....panel raises, of varius profiles.....Can actually cut large decrotive mouldings with it, for say, the crowning of shelves etc.....

Only problem is......you have to learn how to sharpen profiled blades......and few know how to anymore...or want to know.

If interested I'll try and get some photos together.....Your back in Japan again ? ....thought I saw Melbourne under your name there for a while.

-

20th January 2007, 08:38 PM #8

Thanks Lignum

-

20th January 2007, 11:33 PM #9

Ageing, balding,teenager

Ageing, balding,teenager

- Join Date

- Nov 2004

- Location

- Belfast, NI, UK

- Posts

- 40

Thank you! I've just ebayed the dirtiest, most welded up, broken-bits-off 45 you've ever seen and do you know, I think it will do this! Many, many thanks Jake as always, for showing all of us using Chicken Shack Engineering that "IT IS POSSIBLE, JUST DO IT".

Sorry, just came down to earth - this is so simple and straightforward compared to the 1/2" router bit combinations/sets needing vast piles of spondulicks. I can't wait to go out and massacre some old files and have fun.

-

21st January 2007, 03:11 AM #10

Very well done as always, Jake!

Never really thought of raising panels by hand vertically so you've giving me some things to think about.

As to doing and entire kitchen--how does one think it was done in times past? So of course. And as many things done by hand vs. machine, it takes longer.

But it isn't a hard [nor necessarily time consuming] thing to do. At least with a panel raising plane, each panel goes fairly quick. Then too, for most of us hacking wood, it ain't a race, is it? So it really depends on how one wishes to work. Hand tools or power tools and whatever mix of tooling and methods we each want.

Take care, Mike

-

21st January 2007, 07:59 AM #11

pleasure. I'm always on the lookout for beatup parts too. Feels ok to experiement when there worn out.

Chicken shack engineering ! .....this is a world class woodworking shop thankyou very much .

Thanks Mike. I'm right with you on the hand tool/machines debate. Wish I could offer up something more athetically appealing though. A wooden version maybe. anyway.

-

21st January 2007, 08:56 AM #12

Jake

You are a master of the combo planes!!

I understand what Derek means about the photo tutes being a bit hard to follow. What I do is get my own #45 out and try to replicate what you are showing and talking about - it usually becomes clear pretty soon.

I am becomeing more and more a darkside convert. Why? With small kids and a full on daytime job, I often only get to the shed after 9 pm. The neighbours rather object to the powered router and other electron burning - but they don't hear me take of whisper quiet shavings with a plane! Also, I don't build many kitchens - if it is going to be a unique piece, it takes me as long to set up the router as it does to set up the relevant darkside planes.

I like the idea of the LH depth stop - any piccies?

Keep up the great work

JeremyCheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

-

21st January 2007, 11:36 AM #13

Back here again, I was back in Melbourne long enough to find some bits and pieces (The 044 and a 4 1/2 are the picks of the litter) and back here again. Usually being home wears off pretty quickly, but not this time...

Anyways, profiled blades aren't a problem. I use a similar method to you I suspect, get the details with a grinder, hit it with lt the felt and call it good. I don't get troubles with them.

As it is, I can't use the 044 since it's not here yet, and it has no blades, no depth stop and no lever cap thingy. Blades are easy, depth stop equally so, The lever thing I have a plan for, so that's going to be the most tricky part, and even that's a doddle. So not yet, but it is coming in mail, soon I hope.

The blades being 'tungsten steel' are likely something akin to HSS or A2. Problem with these steels is they have trouble supporting shallow sharpening angles, like 25* or so. Bring them back to 30* and the edge will hold up. I think the brittleness is a function of how hard they are, but since they are also tougher, you get a longer lasting edge at a less acute angle. Trying to pull the same trick with regular steel will only end in tears, since O1 will get hard enough, but will be quite brittle.

Says I whose blades make files get scared, and are not at all brittle. Royal PITA to sharpen though.

The proper reason I wanted a 043 or 044 was so I had something to work off when I make my own. Problem solved in the regard at least.

-

21st January 2007, 11:39 AM #14

Senior Member

Senior Member

- Join Date

- Sep 2006

- Location

- Bookham, Surrey, UK

- Age

- 79

- Posts

- 137

-

21st January 2007, 06:47 PM #15

Thanks Paul,,, Jeremy....I can relate to lack of time. But I've got nothing to complain about if you only get shed time after 9pm !....

I'll try and get them pics.

Look forward to seeing what you come up with Schtoo.

Similar Threads

-

Panel raising with the stanley 55

By JDarvall in forum HAND TOOLS - POWEREDReplies: 12Last Post: 31st August 2006, 07:42 PM -

I give up - my Triton won't cut straight. Anyone work out what's wrong from this pic

By toddles in forum TRITON / GMCReplies: 24Last Post: 8th August 2006, 01:54 AM -

Raised panel finishing sequence

By Mitch Harper in forum FINISHINGReplies: 2Last Post: 25th October 2005, 11:16 AM

Reply With Quote

Reply With Quote