Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 31

Thread: shaping plane totes/saw handles

-

4th January 2009, 10:24 PM #16

Senior Member

Senior Member

- Join Date

- Dec 2008

- Location

- Hunter Valley

- Posts

- 298

Ummmmmm,

I'm only

an "Apprentice", but I have restoted a few totes.

Yes, I agree, a Pattern Makers rasp is a desirable tool--but expensive and difficult to obtain.

I use a "Japanese Rasp" (available from Carbatec, and, I'm sure, other suppliers) with two degrees of coarseness, a patternmakers rasp, and assorted woodie and metalworkers' rasps, then those baby sanders on the drill press, in conjunction with abrasive paper, from 60 grit to about 320to finish off.

I use white shellac and wax to achieve their elegant potential.

I do not slavishly follow the original shape, as I have a bloody big mit, and the standard is too small.

Hope this helps,

Jim

-

4th January 2009 10:24 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

4th January 2009, 10:28 PM #17

I'm not sure I'd want to compare my $1 market bargains to Derek's Aurios beauties! My logic is that I can afford to shell out $1 on a tool to abuse while I learn how to look after it, and then if I find I need a better quality tool, I'll know what to look for, and how to look after it.

Cheers, Richard

"... work to a standard rather than a deadline ..." Ticky, forum member.

-

5th January 2009, 09:18 AM #18

Derek

thanks for the links

more tool shops to drool over - or throughregards

Nick

veni, vidi, tornavi

Without wood it's just ...

-

5th January 2009, 11:54 AM #19

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jan 2004

- Posts

- 686

A rasp is an essential tool.

Another way is to carve a bevel onto the profile with a sharp chisel, flat side up, using the point where the ground edge meets the top side of the chisel as a fulcrum/guiding point.

Then, remove the corners of the bevel in the same fashion.

A quick rub across the grain with sandpaper and then with the grain, and it's done.

Took about 15 minutes to completely round the last plane tote I did, about 30" from rough stock to finished article.

In the time it takes to write this, I could have half-rounded the tote.

Cheers,

eddie

-

6th January 2009, 10:35 AM #20

Eddie, I actually did use a chisel and it works ok except in the tight curves. I am impressed with the speed in which you do your totes, maybe you should put out a video

, as I took hours to do mine.

, as I took hours to do mine.

-

6th January 2009, 11:16 AM #21

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jan 2004

- Posts

- 686

Glad that it worked out for you, Tiger. From memory, I had the same issue with the tight corners.

Grab a smaller chisel and pare out the corner. I'm pretty sure that's how I did it. Either that, or a round file.

From a square shape, a bevel gives it 8 corners, and removing the corner of each bevel gives a 16 sided shape, pretty d@mn close to a circle. It doesn't take much effort to round it off from there,

-

7th January 2009, 09:36 PM #22

Senior Member

Senior Member

- Join Date

- Dec 2008

- Location

- 75 km north of newcastle

- Age

- 76

- Posts

- 110

Shaping totes

Shaping totes

I'd be inclined to listen to "me ol' mate 'round the corner, Pommy Phil' as I've seen the dozens of beautiful totes he has created recently. I turn the knobs to suit and his collection of restored planes is wow!!!

Mick (manana)

Why do today that which will wait until tomorrow?

-

7th January 2009, 10:43 PM #23

I use a stiff fibre scrubbing brush to clean files and rasps, never a wire "file" brush.

The Nicholson "rasp" from Bunnies is not the same as the Nicholson #49 and #50, both of which have been the industry standard for a machine-made (and therefore cheaper rasp) for many years. I have not used the latter so cannot comment other than to note that the teeth are (a) machine made, and (b) do not extent to the edges of the rasp.

The advantage of the hand-cut rasp is that the teeth are irregular and this aids in cutting more smoothly.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

8th January 2009, 07:37 AM #24

Thanks Derek for clearing that one up. You may have thrown the cat among the pigeons though with your view about not using a wire brush to clean files, it makes sense though.

-

8th January 2009, 07:43 AM #25

File cards (wire brushes specifically for cleaning files) have been the industry standard since the dawn of shaping wood and metal. Most file manufacturers produce and recommend them. The wire is softer than the extremely hard teeth, so virtually no harm is caused to the file.

Soaking a file in vinegar (or any solution that eats the metal) is far more likely to dull the edges of the teeth.

I coat my files with French chalk to reduce the clogging and it makes them much easier to clean..

I know you believe you understand what you think I wrote, but I'm not sure you realize that what you just read is not what I meant.

Regards, Woodwould.

-

8th January 2009, 08:22 AM #26

Senior Member

Senior Member

- Join Date

- Apr 2007

- Location

- Blakehurst

- Posts

- 167

File cards are great for keeping your files and rasps clean, I can't see how they could damage your rasps?

The Bahco from bunnies is great, maybe I don't know any better because I have never used anything supposedly better than the Bahco.

I just almost finished a new handle for one of my saws and after the rasp I turned to my Bosch Delta sander with all its different fingers etc. (my apologies to the Hand Tool fraternity). It did a wonderful job, that is until I decided it needed more shaping and hit it with the rasp again.

But how do I cut the slot for the saw?Last edited by Socrates; 8th January 2009 at 12:38 PM. Reason: Spelling error

-

8th January 2009, 09:32 AM #27

I don't have any empirical evidence that file cards damage files, but the fact that file manufacturers recommend them and several professional woodworkers do not confuses me.

However acetic acid and citric acid can be used to clean files and rasps very well. It actually sharpens the teeth. In fact you can rust sharpen files and rasps by rusting them lightly and then cleaning with citric acid or electrolysis.

If I had an auriou rasp I don't think I would do this too many times because they are only case hardened.

Cheers

Michael

-

8th January 2009, 11:34 AM #28

Time to clarify a few points.

The recommendation for not using a steel brush comes from a couple of sources, such as Mike Wenzloff who uses rasps and files daily to build his saw handles, and Joel Moskowitz, who manufacturers and sells rasps. They argue that blunting occurs with the steel files.

I began using Aurio rasps about 2 years ago and at that time was also still under the impression that a steel file cleaner was appropriate - in fact bought one and used it briefly. I cannot say (without doing some experimentation with my microscrope) whether the steel files cleaner causes excessive wear on raps. Why bother? I listen to the advice of those I respect in this area. The stiff fibre brush does its job.

Note also that the difference between cleaning and sharpening with citric acid is in both the strength of the solution and the duration the blade is left in it. I have sharpened many files over the years by leaving the blades in a moderate solution (that is, 3 of the small tubs available from most supermarkets tipped into a bucket of lukewarm water) for up to 1 week. By contrast I would leave the Aurio rasp is a 1 tub solution for a couple of hours only. Michael is correct to point out that the Aurios are case hardened, but again this is a recommendation from Mike W, who does this all the time.

With files, the steal of which is tempered differently and this much harder than that of the rasps, the wire file cleaner is probably fine. In fact I still use one occasionally for really stubborn swarf, otherwise use the brush if I can. I try and load the file with chalk - prevention is better than cure - and only push the file in one direction. Hang up the files - steel against steel in a drawer will damage the teeth.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

8th January 2009, 12:08 PM #29

Hi Socrates,

Cutting the saw slot is easier before you shape the handle, but should still be ok, the most popular method is described here...

by Alice Frampton (aka Alf) http://www.leevalley.com/newsletters...5/article3.htm

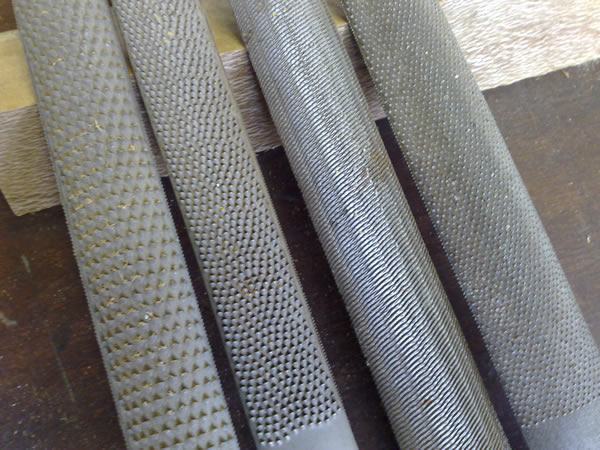

Regarding rasps, and files, compare the different teeth and patterns below.

Going from left to right,

1. Bahco, very coarse, teeth all in rows, removes a lot of material quickly but leaves a poor surface.

2. Nicholson #49 pattern makers rasp, finer teeth, wavy pattern (still machine cut) a good all round choice

3. Bahco metal file, push it the right way and you can get a reasonable finish, no good for removing a lot of material however.

4. Auriou Rasp, (can't remember what grade, 8 i think) hand cut teeth, this is the best of all worlds, removes material very fast and leaves a good finish.

FWIW... Michael Auriou, recommends using a stiff nylon nail brush to clean his rasps, so I guess he knows...

As for the others, I see no problem using a file card for cleaning files. I wouldn't use it on the Auriou however.

I hope this helps clarify the differences..

Regards

Ray

PS Sharpening files in citric works really well...

-

11th January 2009, 02:45 PM #30

As to how long a good rasp lasts, I have no experience of Aurious, but I used a Nicholson pattermakers' for 20 years, pretty heavily. I thought it was getting a bit tired, & bought a new one because I happened to be at Lee Valley a couple of years ago. The new one is sharper, no doubt, but the old one still does a pretty decent job - I've relegated it to a darker corner of the toolbox, but pull it out for any job where there is a danger of hitting something harder than wood. It still cuts better & more smoothly than a Nicholson 'cabinet' rasp which is much younger...So I guess they last well if treated well.

I add my voice in praise of rasps- an essential tool that is hard to beat for rapid & accurate wood shaping. I wouldn't try to compete with Eddie at tote-making ( 15 minutes!), but he can't afford to be mucking about making 'studio' handles

15 minutes!), but he can't afford to be mucking about making 'studio' handles  . However, I reckon I can produce something pretty decent in under two hours with rasps, cabinet file, a small scrapers & just a little sanding. The tight curves at the top (horn) of totes & saw handles & the bottom front curve on totes are pretty taxing even for the tapered end of a Nicholson #49 - I picked up a nice little 6" (Italian, I think it is) rasp from LV that handles these bits a lot better.

. However, I reckon I can produce something pretty decent in under two hours with rasps, cabinet file, a small scrapers & just a little sanding. The tight curves at the top (horn) of totes & saw handles & the bottom front curve on totes are pretty taxing even for the tapered end of a Nicholson #49 - I picked up a nice little 6" (Italian, I think it is) rasp from LV that handles these bits a lot better.

Cheers,IW

Similar Threads

-

Custom or redesigned iron plane totes.

By Woodwould in forum HAND TOOLS - UNPOWEREDReplies: 6Last Post: 2nd October 2008, 03:44 PM -

Blackapple toolworks plane handles

By SilverSniper in forum HAND TOOLS - UNPOWEREDReplies: 1Last Post: 12th July 2008, 08:13 PM -

Replacement totes

By rsser in forum HAND TOOLS - UNPOWEREDReplies: 1Last Post: 3rd January 2008, 09:39 PM -

Shaping saw handles

By Geoffexpat in forum HAND TOOLS - UNPOWEREDReplies: 36Last Post: 26th July 2007, 12:13 AM -

Grinding (shaping) a blade for a scrub plane

By derekcohen in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 3Last Post: 17th May 2005, 03:14 PM

Reply With Quote

Reply With Quote