Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 32

Thread: Workshop storage update

-

27th April 2011, 03:04 AM #1

Workshop storage update

Workshop storage update

I do not post much about my workshop, mainly because it is rubbish compared with many examples I have seen on this forum. While I admire and aspire to a shop with beautifully fitted cabinets, ones that would not look out of place in my kitchen, the thought of all that beautiful hardwood not being used on furniture .. well I just can't do it.

Now I understand that some ... many ... consider their shop as a place of private reflection, where one is free to worship brass and iron idols and icons, or just chat with mates over a beer. So I accept that shop furniture is high on the list of many. Just not for me. I work with recycled woods, many of which are now endangered ... like Jarrah. I bet you think that it grows on trees In fact, the Jarrah forests have been decimated, for railway sleepers, fencing, firewood ... and the forests only grow in Western Australia. And now they have almost disappeared. I'd rather use wood like this for furniture in the house than in the shop.

In fact, the Jarrah forests have been decimated, for railway sleepers, fencing, firewood ... and the forests only grow in Western Australia. And now they have almost disappeared. I'd rather use wood like this for furniture in the house than in the shop.

So I built mine almost entirely from cheap, sustainable Pine, and used a little Jarrah here-and-there to tart it up. Three years ago, following an addition above the garage/workshop, I started from scratch with four bare walls - well, actually three since the fourth was a double garage door. I managed to get as far as a couple of cabinets, one for spokeshaves and braces, and another for rasps and files, and then added a saw till - none of which had doors or were protected against dust. I also constructed a long - open - set of shelves above the workbench for planes. The only cabinet that had a door was the one for chisels.

Dust, dust, dust ... oh how I hate dusting shelves!

This weekend past I decided to add doors to the shelves. This was going to be a quick-and-dirty job, using recycled cardboard (i.e. MDF) .. one morning tops, then I could get back to building something important, like the two campaign chests that were put aside about a month ago and sit there mocking me.

Well it got out of hand. The MDF doors got tarted up with Jarrah edging (OK still cheap-and-nasty, but they will do until the house is full of furniture), then I installed glass in the glassless doors in the spokeshave/brace cabinet (which I had built as part of a magazine article I wrote to illustrate joint making). And finally I rebuild the chisel cabinet to make room for all the new Japanese chisels (Kiyohisa slicks and Koyamaichi dovetail) that replaced a bunch I sold. And after this (so not finally!) I redid part of my hanging tools.

Enough with the words - where are the pictures!?

Just keep in mind that this is not about showing tools. More about tool storage. So if you want close-ups to see the tools, then ask (I am happy to oblige) but the storage has priority.

As I mentioned earlier, my shop is in a double garage and must share space with one car (two others live outdoors). There are power tools as well for the rough work ...

Turn around and face the rear of the garage, and now you are in the handtool shop. Facing you is my small workbench and above this are the MDF-Jarrah doors that now seal the shelves from the dreaded dust ...

The door on the far right is chisel cabinet. Inside it now looks like this ...

The only open section is where I keep the bench planes that are most used, a combination of woodies and Veritas BUs. Since these tend to be larger planes, it is easier to keep them out of the way if there is somewhere convenient to rest them ..

If you now do a left turn and face the far wall, this is what you see ..

That cabinet at the far left was the glassless glass doored offender. No longer. It now has glass ...

After this I realised that I really must fit glass-fronted doors to the remaining cabinets. This will be done next time ...

The lower cabinets were, in fact, a kitchen (well I thought that was just desert) that I was given by a neighbour who was upgrading. The tops are 1 1/2" plywood.

This cabinet provides easy access to rasps and plough planes. The drawer contains files in a roll.Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th April 2011 03:04 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

27th April 2011, 03:05 AM #2

The hanging tools. I find it easier to keep as many of the layout tools close at hand this way. I have shown this before so I will only show something new, this being the inclusion of my hammers/mallets. Keeping them off the bench top is a biggie. The bench is small (just 5 foot) and clutter makes it smaller (a new bench is on the drawing board ... one day).

Hope this provides some ideas for some. Feel free to ask for details, or post pics of your own solutions.

Oh, and see Ian - absolutely no competition for your tool cabinet!

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th April 2011, 08:36 AM #3

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

A true Darksider's aladin's cave!!

-

27th April 2011, 10:03 AM #4

Derek - I would be quite content to spend my days in your shop, as-is, though I MIGHT have to substitute more glass for those MDF door panels....

Couple of points: Firstly, you have waaay more tools to store than I do. Secondly, I have quite a bit more room, and it's all MINE - I don't have to share it with any cars. (One of which is suffering severe incontinence, too, judging by that large oil-patch on the floor!). I share your detestation of dust, and despite my DC and reasonable care, I just can't prevent it from getting all over anything left uncovered, either, so just about everything in my place has to be behind doors, too.

I freely admit my tool cabinet is a bit of a conceit - but it does give me some satisfaction to see cabinet-making tools sitting in something that looks like a cabinet. However, anything your cabinets lack in finesse on the outside is more than compensated for by the bling inside!

My boast, too, is that all the benches & cabinets in my shed are made from recycled wood & cast-offs. We are a bit more fortunate in having much more to choose from over this side of the Nullabor, & I'm very lucky to have plundered some high-yielding skips, and had people give me some rather nice 'worthless' wood, over the last 20 years. Even better, I've had room to store the spoils (& a very tolerant spouse) while I got around to fitting out the shop!)

Over the last 5 years, I have gotten it kicked into shape, pretty well, which is good, as I intend to spend many happy hours there over the next few years. Is all this organising activity a precursor to spending more time in the shop, too?

Cheers,IW

-

27th April 2011, 01:46 PM #5

He jests to much me thinks.

All thats wrong with that workshop is the stain on the floor from the Volkswagon simple fix some kitty litter a Gernie and a drip tray with sawdust.

simple fix some kitty litter a Gernie and a drip tray with sawdust.

Once again mine is over flowing.

-

27th April 2011, 05:12 PM #6

That stain. So sad.

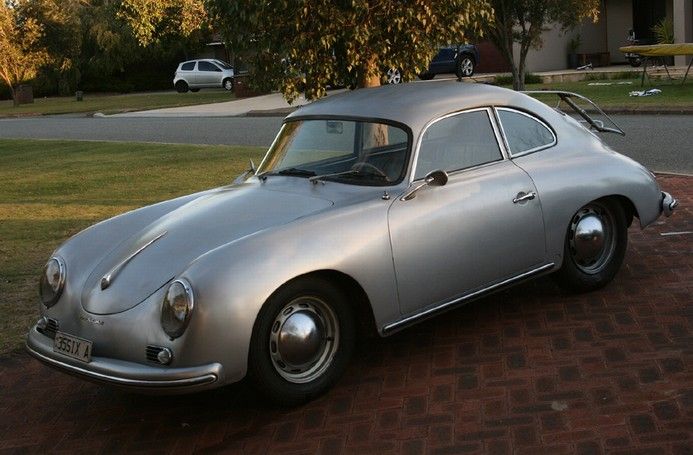

It is all that remains of the Porsche 356 that parked there. 11 years of restoration, and sold it about 9 months ago. Replaced with something even more fun

It is all that remains of the Porsche 356 that parked there. 11 years of restoration, and sold it about 9 months ago. Replaced with something even more fun

Ian, I love your cabinets. One day, when the List is complete inside the house, then I will do the same. Gad, I find it hard enough as it is to take the time to build a bigger bench. At the moment I am content that wood (in a finished form) goes out of the workshop rather than only stays inside it.

One day ...

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th April 2011, 07:02 PM #7

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2009

- Location

- Sydney

- Age

- 37

- Posts

- 2,724

Great storage and beautiful hand tools Derek!

I'm interested to know if you could only have one jointer and one smoother, what would they be?

Andy

-

27th April 2011, 07:48 PM #8

-

27th April 2011, 08:29 PM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2009

- Location

- Sydney

- Age

- 37

- Posts

- 2,724

Imagine Derek with only two hand planes! The poor bloke.

My guess would be the shop made jarrah jointer and the Marcou smoother?

-

27th April 2011, 08:40 PM #10

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th April 2011, 08:49 PM #11

Think that stain is newer than 9 mnths Derek OH&S danger zone signs required.

-

27th April 2011, 09:00 PM #12

You're correct. The two pics of the empty garage were taken after I sold the 356 and made room for the new (old) car that replaced it. So the oil stains are fresher than 9 months.

This is the 356 that I sadly sold on (too much work still to do, although it was licenced and driving at the time) ...

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th April 2011, 10:40 PM #13

Thank you for sharing this has given me some ideas now to just put this into practices.

-

27th April 2011, 10:58 PM #14

-

27th April 2011, 11:26 PM #15

So how easy is it to get to the top row of chisels on the left hand side of the cabinet?

Hi Ian

Easily enough - as long as you remove the chisel in the row in front of it.

Having said that, the reason the bench chisels are at the rear is that they are least used. These days I find that I can use the dovetail chisels in their place - which is not surprising sincde they are bench chisels, just with a different profile.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Workshop Update.

By Alex.R in forum WOODWORK PICSReplies: 19Last Post: 26th February 2010, 08:34 PM -

Workshop rebuild progress - Update #2

By derekcohen in forum WOODWORK - GENERALReplies: 7Last Post: 22nd August 2008, 03:11 AM -

Small Workshop Tour...update

By Dust Mite in forum WOODWORK PICSReplies: 12Last Post: 28th February 2007, 05:32 PM -

workshop storage solutions - show us your rack

By boban in forum WOODWORK - GENERALReplies: 16Last Post: 12th September 2005, 09:09 AM

Reply With Quote

Reply With Quote