Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 106 to 120 of 1386

-

31st October 2008, 11:22 AM #106

Guppy, since I submitted the data which seems to be causing you some worry, maybe I can help clear thngs up.

Yes, there is quite a difference between the blades on my 6 and my 4 1/2, as far as length of slot, and position of slot. But it doesn't make a bit of difference. I've just spent a few minutes in the shed confirming that I can interchange the blades between by 6, 7, and 4 1/2 without any drama. All the differences prove is that these values (slot length and distance between top of blade and slot) are not critical, there is a fairly wide range of values that will work.

What is critical is the width of the blade, and the position of the slot in the chipbreaker.

-

31st October 2008 11:22 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

31st October 2008, 11:27 AM #107

Yep I can confirm that the #6 and #4/1/2 are the same. Here is some raw data I pm'ed Helmut, that gives the most important measurements.

Cheers

Michael

Stanley #6

bottom of CB to bottom of YH 95.6mm

YH 4.7mm x 12mm

With an 3mm Academy blade fitted 1mm from CB this gives:

maximum retraction of 1.6mm

maximum extension of 0.8mm (CB touches mouth)

bottom of CB to ctr blade mounting screw 80.5mm

Mouth to bottom of mount screw 57.8mm

Mouth to top of lateral adjuster button 114mm

Top of mounting screw diameter 10.3mm

Academy blade diameter of keyhole 18mm, slot 108mm x 11.65mm

Stanley #5 1/2

Blade slot 119mm by 12mm

mouth to mounting screw 58.2mm

mouth to lateral adjuster 115mm

CB is not standard so can't use it

Stanley 4 1/2

bottom of CB to bottom of YH 96.2mm

YH 4.7mm x 12mm

maximum retraction of 1.8mm

maximum extension of 1.5mm

bottom of CB to ctr blade mounting screw 80.5mm

Mouth to bottom of mount screw 57.8mm

Mouth to top of lateral adjuster button 115mm

Top of mounting screw diameter 10mm

Stanley #5

bottom of CB to bottom of YH 92.4mm

YH 4.7mm x 12mm

maximum retraction of 1.3mm

maximum extension of 1.0mm

bottom of CB to ctr blade mounting screw 77mm

Mouth to bottom of mount screw 57.0mm

Mouth to top of lateral adjuster button 111mm

Top of mounting screw diameter 10mm

Stanley #3

bottom of CB to bottom of YH 90.2mm

YH 4.7mm x 12mm

maximum retraction of 0.4mm

maximum extension of 1.4mm

bottom of CB to ctr blade mounting screw 76mm

Mouth to bottom of mount screw 53mm

Mouth to top of lateral adjuster button 109mm

Top of mounting screw diameter 10.3mm

-

31st October 2008, 12:02 PM #108

I would recommend that everyone get all you blades with a cap irons as their is no guaranty in that I do not know at all if the older style cap iron you have will fit your new blade. I can however guaranty that the lever cap provided with my plane blade will fit.

In addition a thicker and more substantial cap iron is as important as the blade for Stanley planes stiffens your blade more and will give you a better planned finish. That is why many modern plane maker all have some variant on the flimsy Stanley lever cap.

-

31st October 2008, 12:09 PM #109

Senior Member

Senior Member

- Join Date

- Oct 2007

- Location

- Canberra

- Posts

- 195

As per my PM yesterday, I would like to order 8 capirons to fit the 8 blades I ordered.

I'll finish off the remaining Hock measurements tonight.

cheers

Tom

-

31st October 2008, 12:25 PM #110

Hi TS,

I have stayed out so far thinking this group buy was just 2.5mm stanley plane blades but..

seeing as I see you are getting some 6mm stuff, I am interested in thick blades for infill planes, same as the Hock blade but a little thicker

That's the 3/16 Infill Hock Blade, basically I am looking for the same but in 6mm M2 ...

Overall dimensions 55 mm x 6 mm x 180 mm

If this is outside the scope of the current purchase, don't worry. I have some 01 steel on order.

On the other hand, if you have a surplus of 6mm you need to allocate, I would be interested in a few of the above.

Thanks.

Regards

Ray

-

31st October 2008, 12:28 PM #111

-

31st October 2008, 12:34 PM #112

Hi Ray

We can get you some 50 x 6 x 200 mm or 60 x 6 x 200 mm plane blades, without the slot cut out of the middle.

With a 6 mm thick blade you do not need a lever cap, Sauer & Steiner makes some lovely infills and they have really made the point.

How many would you like?

-

31st October 2008, 12:41 PM #113

Mic as I said:

I have not gone out and tested hundreds of lever caps with these new blades. I do not tried your lever cap with my blade. I do not know if they will fit. They may. However they many not. To be safe I would order a cap iron for under $10 it will give you piece of mind. If your lever cap does not fit and you end up with a blade that you cannot use because yo cannot fit the lever cap and therefore cannot adjust your blade then that will be a problem.I do not know at all if the older style cap iron you have will fit your new blade. I can however guaranty that the lever cap provided with my plane blade will fit.

-

31st October 2008, 12:47 PM #114

Helmut there's no need to get narky, I'm just trying to get to the bottom of what you mean by "fit", Can you just say you mean they might be narrower or wider. Are there other reasons why it might not fit and what are they, I'm trying to understand here. Now you're talking about lever cap, I thought that was the cap that has the lever on it for locking the whole thing down. Is the lever cap the chipbreaker/cap iron. I'm confused.

Cheers

Michael

-

31st October 2008, 12:48 PM #115

Hi TS,

Put me down for 3 of each, that is

3 off 50x6x200

3 off 60x6x200

Not sure I understood the lever cap reference, I assume you mean cap iron/chip breaker.

I'm a big fan of Konrad's infill smoothers, but they all have cap irons, so now I'm a bit confused as to what you meant?

Regards

Ray

Edit: Sorry, I re-read a few times.. I understand now, no slot means no cap iron, that will be fine.

-

31st October 2008, 12:48 PM #116

-

31st October 2008, 01:32 PM #117

RayG I have added you and Ironwood I have re-added you. Yes they will be made from M2.

RayG I mean no chip breaker for some of Konrad's planes and he says it works fine, just like HNT Gordon.

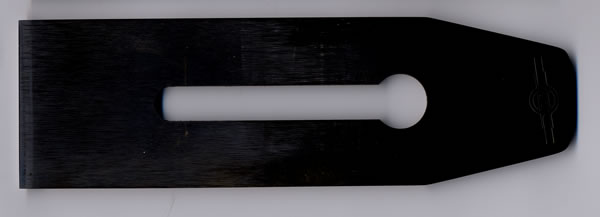

Attachment 87313

Mic - My concern is that the holes may not line up, the other concern is that the mounting screw of you old chip breaker would be to short now with the thicker blade. You choice.

-

31st October 2008, 01:33 PM #118

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2001

- Location

- ACT

- Posts

- 455

Hi TS,

If you still have space on the sheet, please put me down for two blades - one each to suit:

No. 4 @ (2'' wide)

No. 6 @ (2 3/8'' wide)

Thanks,

Steve

-

31st October 2008, 01:41 PM #119

Hi ts can I add another

- No. 4 1/2 @ (2 3/8" wide)

btw to be sure, is the price of each blade $15? plus $8 for chipbreaker?H.S.

-

31st October 2008, 01:51 PM #120

Ah, okay, that threw me too, now I understand.

Let me be absolutely clear here Helmut. I'm trying to decide whether to get a whole set of cap irons as well. I can see only reasons why the original cap iron WILL fit, MUST fit, and no reasons (apart from it may be a bit narrow) why it could not fit. The cap iron receives the yoke through the blade iron, delivers the blade iron in the correct range at the mouth and the lever cap mounting screw passes though the blade iron and cap iron. The dimensional relationships of the yoke, mouth, levercap mounting screw are determined by the plane, if the Plane iron is manufactured to clear all these bits and pieces, the cap iron MUST fit. If the blade is a bit narrower than the original cap iron, I can live with that, if it is a bit wider I possibly can live with that. I think it is better to be clearer on this point rather than just a vague warning that it may not fit, it may influence people's decisions to buy cap irons or indeed whther they purchase a blade iron at all (if they think they must also purchase the cap iron)

Cheers

Michael

Similar Threads

-

History of Stanley/Bailey Bench Planes

By silentC in forum HAND TOOLS - UNPOWEREDReplies: 29Last Post: 1st December 2010, 08:27 PM -

Bulk Brass Order

By thumbsucker in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 149Last Post: 3rd November 2008, 08:58 AM -

Replacement Stanley blade

By matto1 in forum HAND TOOLS - UNPOWEREDReplies: 2Last Post: 13th August 2008, 09:49 PM -

Scraper insert for stanley bench planes

By Woodlee in forum HAND TOOLS - UNPOWEREDReplies: 4Last Post: 12th May 2008, 12:26 AM -

Replacement Blade For Stanley No 6

By Pat in forum HAND TOOLS - UNPOWEREDReplies: 7Last Post: 27th June 2005, 10:27 AM

Likes:

Likes:

Reply With Quote

Reply With Quote