Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 10 of 10

Thread: Steampunk Mitrebox

-

6th August 2013, 01:10 AM #1

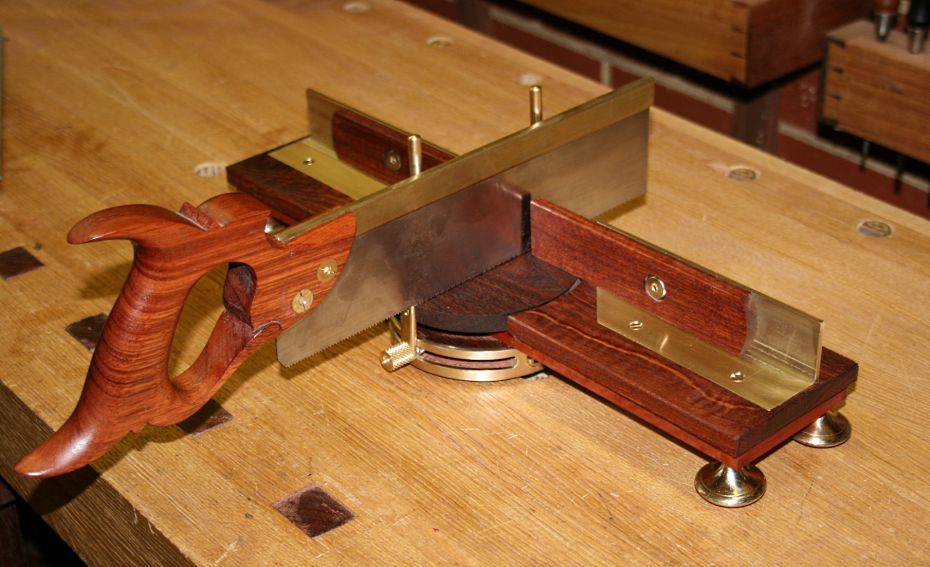

Steampunk Mitrebox

Steampunk Mitrebox

During my recent build of the kist I was sawing mouldings on a Millers Falls Acme 74A, and realised that it was similar to cracking nuts with a sledgehammer. I would kill for a small version of this mitrebox, but they are rare as rocking horse droppings and twice as expensive.

I usually build a tool between furniture projects and, consequently, decided this one would be my own version of a small MF .... well, sort of ...

The mitrebox is Jarrah and brass, just under 17" in length, 4" deep, and 3 1/4" to the top of the fences. It is used with an 11" carcase saw I made 2 years ago. This has a 2 1/4" plate and is filed 14 ppi crosscut.

In order to make the depth as shallow as possible, the turntable (for the saw) needed to be small, and this led to placing it pivot point in the centre of the bed. To close up the gap in the fence that results from this, the fence contains a subfence that slides back-and-forth ...

With the fences back, the mitrebox is optimised for mitres ...

Here is the same moulding from the kist ....

A comparison with a MF Acme 74A ...

The heart of the saw-holding mechanism is a plate with rare earth magnets ...

Another shot, as well as the angle locking mechanism ...

The locking mechanism is built on a morticed Jarrah disk ...

The fence is a 1 1/4" x 1 1/4" brass angle section, with Jarrah subfences. At the rear is a slide adjuster ...

You can make out the angle settings. The fence is set up for quick adjustment to 45 degrees either way and 90 degrees. It has a variable range from about 40 degrees. The saw can be used on either side of the fence.

Here is a close up of the settings ...

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th August 2013 01:10 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

6th August 2013, 09:44 AM #2

That is really nice work Derek.

…..Live a Quiet Life & Work with your Hands

-

6th August 2013, 12:08 PM #3

Oi, Derek, you haven't shown us the guts of the turntable - is it all home-manufactured, or did you press some scavenged parts into service?

Looks great, nicely done, and I've thought about making something along those lines myself, but in the end, impatience gets the upper hand & I just make a wooden mitre box out of whatever scrap is on hand, to fit the particular job I'm in the middle of. (Which then accumulate on a shelf & gather dust & are rarely used again!). Or when I'm really impatient (which is possibly more often), I mark out the mitre, whack it out freehand with a bit of margin for error, then plane to fit. Some blokes are enviously methodical.

Also, it looks like your saw rides on the wooden block and the magnets are recessed slightly so you don't have metal rubbing on metal, but won't you still end up with a pretty highly-magnetised saw blade, and isn't that a damn pest? I hate it when any tool of mine gets a bit magnetised. Even though I try to keep all metalwork to a separate area, they seem to be able to find iron particles from 50 feet away...

Cheers,IW

-

6th August 2013, 12:50 PM #4

Hi Ian

It looks like i shall have to dissemble the mitrebox for photos as I have had several requests. Fortunately it is just screwed together.

With the exception of the feet, which are modified drawer handles, I built everything. Amazing what one can do with a Dremel and files!

Magnetisation? Yeah, it bothers me generally. I avoid placing tools (chisels, etc) on magnetised racks. How this will affect a saw which gets occasional sharpening only (compared to a chisel or plane blade) is something we will only find out in a year or so.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

6th August 2013, 01:00 PM #5

Didn't think you'd get away without showing us, didya??

Yeah, it was sharpening that I had in mind, really. If the saw does get strongly magnetised in use it is going to be a real nuisance. As you say, you will soon know. You could always scout around & see if you can find one of those old recording tape de-magnetisers that still works...

Cheers,IW

-

7th August 2013, 08:37 PM #6

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2005

- Location

- Yangebup, Perth

- Posts

- 444

Nice work Derek,

De-magnetize? Just give it a good knock and it'll demagnetize.The world is a comedy to those that think, a tragedy to those that feel.

-

8th August 2013, 02:34 AM #7

I added a simple base, to enable the mitrebox to be clamped on a benchtop ..

I plan to make a depth stop to control the depth of cut. In the meantime I will use a simple sacrificial board to avoid cutting into the turntable. The workpiece will sit on top of this board.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

8th August 2013, 05:52 PM #8

Jim

Jim

- Join Date

- Feb 2008

- Location

- Victoria

- Posts

- 3,191

I enjoyed seeing this Derek and not just for the workmanship. I finally decided to find out what steampunk means.

Cheers,

Cheers,

Jim

-

8th August 2013, 06:14 PM #9

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Dec 2010

- Location

- Melbourne

- Age

- 79

- Posts

- 601

What a great thing to make,just fab. Wish I had the skill to do stuff like that.

-

11th August 2013, 04:43 AM #10

Thanks all.

The information, including pictures and construction details, is now on my website ...

http://www.inthewoodshop.com/ShopMad...kMitrebox.html

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Steampunk Build

By Jugtones in forum MUSICAL INSTRUMENTSReplies: 22Last Post: 28th April 2011, 02:21 AM -

Timely Steampunk

By Penpal in forum WOODTURNING - PEN TURNINGReplies: 13Last Post: 28th March 2011, 10:11 AM -

Steampunk - What a web site :)

By Lignum in forum Links to: WEB SITESReplies: 3Last Post: 16th December 2007, 07:02 AM -

Stanley mitrebox 246?

By spoinky in forum HAND TOOLS - UNPOWEREDReplies: 0Last Post: 15th November 2006, 03:52 PM -

Stanley # 60 Mitrebox

By George Radion in forum HAND TOOLS - UNPOWEREDReplies: 0Last Post: 17th October 1999, 11:51 PM

Likes:

Likes:

Reply With Quote

Reply With Quote