Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 7 of 7

-

21st June 2015, 10:33 PM #1

Novice

Novice

- Join Date

- Mar 2010

- Location

- New Zealand

- Posts

- 20

5/8" miter slot in Bursgreen Wadkin 12" table saw worth changing to 3/4"?

5/8" miter slot in Bursgreen Wadkin 12" table saw worth changing to 3/4"?

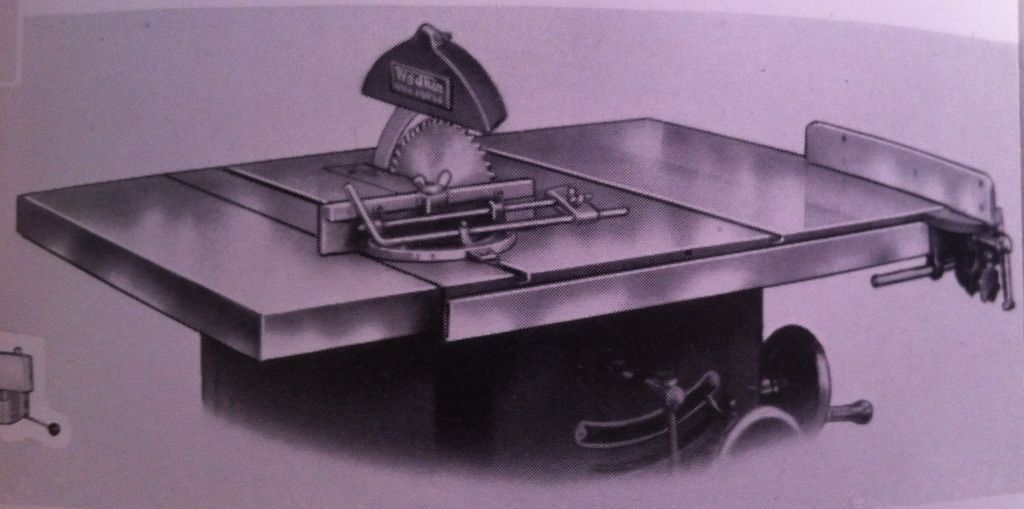

I hope this is the best place to post this, wasn't sure if it should be here or in "Antique Machinery". I recently purchased an old 12" Bursgreen Wadkin Tablesaw. I've been investigating a replacement miter gauge, and realised the slots on the benchtop are 5/8", not 3/4" which all the replacement miter gauges are designed for. So my options are:

1. Stick with current miter gauge and make a sled or two with custom made 5/8" guides.

2. Have the slots milled out to 3/4" so it is the current standard size to fit all the after-market accessories

Below are photos of the saw, I'm looking for a manual on the saw or any information if anyone has some. There is no name plate on the saw, it looks similar to the Wadkin AGS 12" but the canting wheel is on the opposite side, the motor is inside the cabinet and has the riving knife that rises with the blade. Has a 3hp 3-phase motor. Still have to hook it up and run it, contemplating pulling it all down to check bearings etc before connecting it up and using it. Once I start using it I know I wont get round to refurbishing it.

.368041226.jpg 368041234.jpg 368317208.jpg 368317215.jpg

Also looking for opinions on what to do with the fence, it has the old square solid rail that the fence clamps with a bolt (twisting the handle on the fence which tightens on to the rail) rather than a cam lock system. The bolts holding the rail to the saw are broken and I have to drill out the old bolts to replace them. Wondering if I would be better off making/replacing with a new improved system like the unifence or repairing the old one.

I have the equipment and skills to do all the work other than machining the miter gauge slots, would have to take the top to a machine shop for that.

Thanks for any ideas you can offer.

Steve

-

21st June 2015 10:33 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

23rd June 2015, 08:28 AM #2

Hi Steve,

What makes you think its a Wadkin ?

I would not be re-grooving the table, just modify your miter gauge.

The fence I would stick with, I'm a stickler for keeping old equipment original and together.

just my 2 cents...

Melbourne Matty.

-

23rd June 2015, 09:36 PM #3

Senior Member

Senior Member

- Join Date

- Oct 2007

- Location

- Tasmania

- Posts

- 132

Hi Steve,This link might help you search for more information https://forum.canadianwoodworking.co...-an-addiction&

-

24th June 2015, 08:11 PM #4

Novice

Novice

- Join Date

- Mar 2010

- Location

- New Zealand

- Posts

- 20

Hi Matty

I thought it had "Wadkin" marked on the bottom LHS of the base, it does have Bursgreen on the blade guard, can't check that at the moment, it's at another property we are slowly moving in to. From the link jrock_au provided it looks like the saw I have is very similar to a Bursgreen MY.

I used to be a stickler for keeping old equipment original, however I've found, that for me, it's better to make changes that improve the operation of the item than stay original for originals sake.

I can cope with the 5/8" miter slots if I can get, or easily make the runners to use for a sled etc. But that does restrict me to any jigs, miter gauges or sleds I make to this one saw rather than sharing with other equipment with 3/4" slots. At the moment with setting up my workshop I don't know how big an issue this would be, I currently only have one other piece of equipment with miter slots and it is 3/4".

The fence rail is only short, if I put an apron extension on the RHS of the saw I'll need to replace/extend the rail which will need to be drilled, tapped or welded and possibly be just as much work as upgrading to another rail system. I've used an old Dyco saw with a similar fence locking mechanism to this Bursgreen saw, I found the screw locking lever to be frustrating because when tightened, the twisting of the bolt directly against the rail would would move the fence slightly. This movement could be overcome by putting an intermediary piece of shim to go between the bolt end and the rail, but holding the shim in place when the bolt loosens off is the problem.

Thanks for giving me the space to share the pros and cons of making the changes.

-

24th June 2015, 08:18 PM #5

Novice

Novice

- Join Date

- Mar 2010

- Location

- New Zealand

- Posts

- 20

Thank you for the link. From that it looks like I have a similar saw to the Bursgreen MY. The image helped me understand how the micro adjuster for the fence works, mine is missing the piece that locks the rod to the fence rail, now I know what it looks like I can make one if I choose to stick with this fence.

-

25th June 2015, 04:31 PM #6

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Hi Steve,

Sorry I'm late to the party, I missed this post (limited time and just been checking the "antique" sub forum, so you flew under the radar).

That's a very nice and still very practical saw, congratulations on your acquisition . As Matty has already suggested, it's likely to be a Bursgreen MY as apposed to a Wadkin Bursgreen MY, meaning this one was built before the takeover and is pre 1955, so she is doing alright for being over 60 years old. It would be good if you could upload an image of the machine plate (when you get a chance), and perhaps some other angles to help with identifying?

. As Matty has already suggested, it's likely to be a Bursgreen MY as apposed to a Wadkin Bursgreen MY, meaning this one was built before the takeover and is pre 1955, so she is doing alright for being over 60 years old. It would be good if you could upload an image of the machine plate (when you get a chance), and perhaps some other angles to help with identifying?

I agree with this statement, but still agree with Matty. My approach is always, why do I need to change it (do the pro's outweigh the con's), is there a workaround so I can keep it the same and still achieve what I need, and then lastly if I am going to change it, can I do it in a way that it can be changed back.

To me what screams the loudest with this is it can't be reversed. I think this is one of those times I would investigate a workaround, and perhaps live with it for a bit, before making a irreversible change (most probably wouldn't notice you changed anything, other than existing accessories don't fit, but I question the cost vs benefit of doing it). Depending on what you plan to make the bars or runners out of, hardwood, UHMW plastic (then it would seem you have the saw to make them), and I would imagine even getting a length made of steel would be less than having someone machine the slots for you. Again this is just my 2 cents, but if it was me, I would try to work with it first, use the saw for a while and then if I couldn't live with it, take another look at what you want to do.

My main concern with swapping the fence is from the looks of it, you are loosing a very solid fence, with micro adjust.

This is my table saw (https://www.woodworkforums.com/showth...67#post1705667).

There is a lot I like about my saw, but the number one things are the fence locks down solid, it has a short fence (for safety, reducing the risk of a kickback), and it has micro-adjust. To me these are pretty important features of a fence, and from the looks of it, although mine may outweigh that one , I think that fence also has these features.

, I think that fence also has these features.

If you have never had micro-adjust on a table saw you will never want to go back when you get it.

Here is an image of the MY with the optional side wings:

So this is what you are basically looking to do on the RHS?

The catalogue states your saw has a maximum ripping width of 13" (remember this fence design locks from the left, so the fence will likely extend right over to the spot that the bar ends), if you were just after a bit more, I wonder if you could look at just shifting the bar to the right a bit (this means possibly sacrificing being able to have the fence to the left of the blade, but depending on what work you do, this may only need to be done very rarely, and then you still have the option to move the rail). Another possible work around could be just to have another section made, which is secured to the wing, this could just be butted up to the existing bar (any issues with locking on the join, could probably be avoided with the micro-adjust). Obviously getting another piece made and drilled (if you don't have any way of drilling the hole), is a cost, but you will spend a lot more on a new fence, which depending on what you get, may not be as good as what you have in front of you.

Usually when locking metal to metal, what they did was have a small piece of brass (round bar), this would sit in the hole, between the locking bolt and the flat bar. This was designed to prevent wear marks on the flat bar, but also as you say, prevent unintended movement. It was long enough that it did not fall out when moving the fence (like a piece of shim would). Does this look like your fence was designed this way (it was fairly common for machines of this era)? Also remember you have the micro-adjust, so any movement in locking down is not a problem. With my fence, I simply get it close, lock it down and then micro adjust (I've gotten lazy lately and find I don't even lock down the micro-adjust, it doesn't move).

Obviously this is only my 2 cents, and at the end of the day it's your table saw, and you will be the one using it. I hope I didn't come across as pushy (I just read back what I have written, it does sound a bit pushy , not intended, just trying to help).

, not intended, just trying to help).

Whatever you do, I'm glad you have saved this old machine, and I would certainly like to see more of it, when you get a chance.

Cheers,

Camo

-

25th June 2015, 10:43 PM #7

Novice

Novice

- Join Date

- Mar 2010

- Location

- New Zealand

- Posts

- 20

very useful advice

very useful advice

Hi Camo, so pleased you managed to join the party, late comers always welcome.

I will take and upload more photos when I see it next. Where will I find the "machine plate" on this saw? I don't remember seeing one, the saw has had modifications to fit dust extraction by the previous owner who may have removed the machine plate during the work.

I am the same, if I can effect a change that can be reversed I will do it that way. The reason for asking on the forum was really to enable me to have the conversation and help thinking through whether I can get good use out of it like it is, doing the minimum repairs/changes on the saw to be able to start using it.

I do like your suggestion of using the saw as it is for a bit to see how it goes. I started thinking that once I realised how the micro adjuster works for the fence. The adjuster is seized at the moment, but now I know the part I need to make for it to be usable again, loosening the adjuster is the easy part.

Haven't used a fence with micro-adjust which again is why I started this thread to determine the good and bad points of what I already had. So thank you again for pointing these out to me.

Yes this is basically what I'm looking at doing and was thinking of moving the current rail across to see if that will be all I need for extra movement. Read an interesting post on the use/need of 30" or 50" rails on saws and that most of the time we only use the first 20" or so. I have a track saw so don't need to cut panels or large widths on this. I have all the metal working equipment to drill, cut, thread, weld any changes I make to the fence. My little mill isn't long enough to cut the slots on the table otherwise widening the slots to 3/4" would happen.

You have a catalogue of the MY? May I see it please? I've contacted Wadkin in the UK to see if they have any information on the saw but haven't heard back from them yet.

I'll take a closer look at that part of the locking mechanism when I'm at the saw next time and see if there is space for the round bar of brass to fit.

Not pushy at all, I like to be challenged on my ideas, makes me think more deeply. Thanks again for such an in-depth reply.

Similar Threads

-

wadkin bursgreen 10" table saw

By jrock_au in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 48Last Post: 25th July 2017, 09:30 AM -

Wadkin Bursgreen tilting Arbor AGS 10" table Saw

By auscab in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 21Last Post: 10th September 2013, 11:53 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote