Picture(s) thanks: 0

Picture(s) thanks: 0

Results 106 to 120 of 122

-

8th October 2022, 04:15 PM #106

Member

Member

- Join Date

- Dec 2015

- Location

- Melbourne

- Posts

- 56

Yeah Iíve measured, and issue is, if I pull it straight across to where door is, I donít think the planer/thicknesser side of the machine would quite allow timber to go out door. The only solution would be a 180 spin, then position near door. Iíll look more closely at this, but Iím pretty sure Iíd need to do the spin sadly......

-

8th October 2022 04:15 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

8th October 2022, 04:16 PM #107

Member

Member

- Join Date

- Dec 2015

- Location

- Melbourne

- Posts

- 56

-

8th October 2022, 07:03 PM #108

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

Another issue at least with Hammer/Felder machines is that dust extraction is not an option so at all times while cutting it must be used or the internal ducting in the machine will simply block up. I don't think moving a machine weighing the thick end of 400kg is even feasible let alone spin it in the process. I had a machine I think may have been nearly that heavy on casters and trying to move it on a smooth yellow tongue floor happened a few times before I decided it was simply too heavy and that was when I was young, fit and stupid, today I couldn't do it. I also don't think it is a good idea as these European sliders do require calibration and periodical checking and that is when they are static in one position. Here is a link to setting up a slider which Greg would be familiar with.

CHRIS

-

9th October 2022, 07:57 AM #109

Member

Member

- Join Date

- Dec 2015

- Location

- Melbourne

- Posts

- 56

Thanks Chris. I hear you. Yeah moving dust collection is certainly a further issue. As for moving at all, given these units are often sold to people like me with little space and the need to move it under various circumstances, I'm surprised they don't offer better solutions to this. I tried the Sawstop version with one of the Professional series saws (footpedal to lift, 4 caster system, 220kg) and it really was a breeze).

-

9th October 2022, 08:00 AM #110

Member

Member

- Join Date

- Dec 2015

- Location

- Melbourne

- Posts

- 56

-

9th October 2022, 08:04 AM #111

Member

Member

- Join Date

- Dec 2015

- Location

- Melbourne

- Posts

- 56

-

9th October 2022, 11:06 AM #112

My machine doesnít go out of calibration when I move it. I use a pallet jack, and have in the past used the Felder mobility option. I use a pallet jack because I store my machine with the P/T side against the wall which rules out the Felder option.

Maybe you would be better served with a planer/thicknesser combo and a seperate saw? Much easier and lighter to manage and the saw could spend most of its time in position, since you probably use it ten times more often that the p/t.It's all part of the service here at The House of Painô

-

9th October 2022, 12:42 PM #113

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

I have just re-read the posts from Mat and I think I would go to two separate machines. A short stroke slider requires about the same floor area as a table saw and the in feed and outfeed are exactly the same when cutting the same bit of timber on both machines. The plus bit of two machines for me would be it is far easier to move the thicknesser outside of the workshop when needed even if it was just to create space and not to use it. When I bought my slider Felder tried to talk me into buying a combination machine but I am not good enough at planning so it was out of the question.

When I sold Cleavue and got all the stock out of it the first thing I did was totally empty it and ruthlessly get rid of junk that had been laying around for years and all the old machines I had got sold, that was the single best thing I did. I had a very big mezzanine shelf at one end and all the junk that was on that either went to the tip, was given away or sold and the shelf largely demolished and to give you an idea it was 7.5 x 2.4 metres and had a lot of stuff on it. Air space if it can be used is a very good way of increasing the workshop size by clearing the floor if it is workable. I am not very tall so I had no issue with less head height but visitors did and needed to be aware of it. Workshops get used for storage and I think a small workshop needs to avoid that trap at all costs. Mine is by most standards pretty big and even using my minimalist approach it is too small because I like to keep machines against the wall if at all possible.

To give you an idea of where I started from my slider sat on the shelf at Felder for over twelve months because I had nowhere to put it. Felder were very good in that aspect as they stored it free of charge and never once asked me to take it home.CHRIS

-

9th October 2022, 01:05 PM #114

Mat, choosing the Hammer machines I have, rather than one combination Hammer, should provide you with more options for space and ease of use.

The A3-31 combo thicknesser-jointer does not take up much space. Here is mine in the corner of my garage ...

Here again, and close to two other machines ... but the space is fine for me.

This is a photo of the K3 slider shortly after it came to live with me. Its footprint is smaller than the contractor tablesaw it replaced. The wagon is 1250mm long - absolutely perfect for my needs (solid wood, not sheet goods) ...

The K3 could easily be positioned where the bandsaw currently stands. That would be sufficient room.

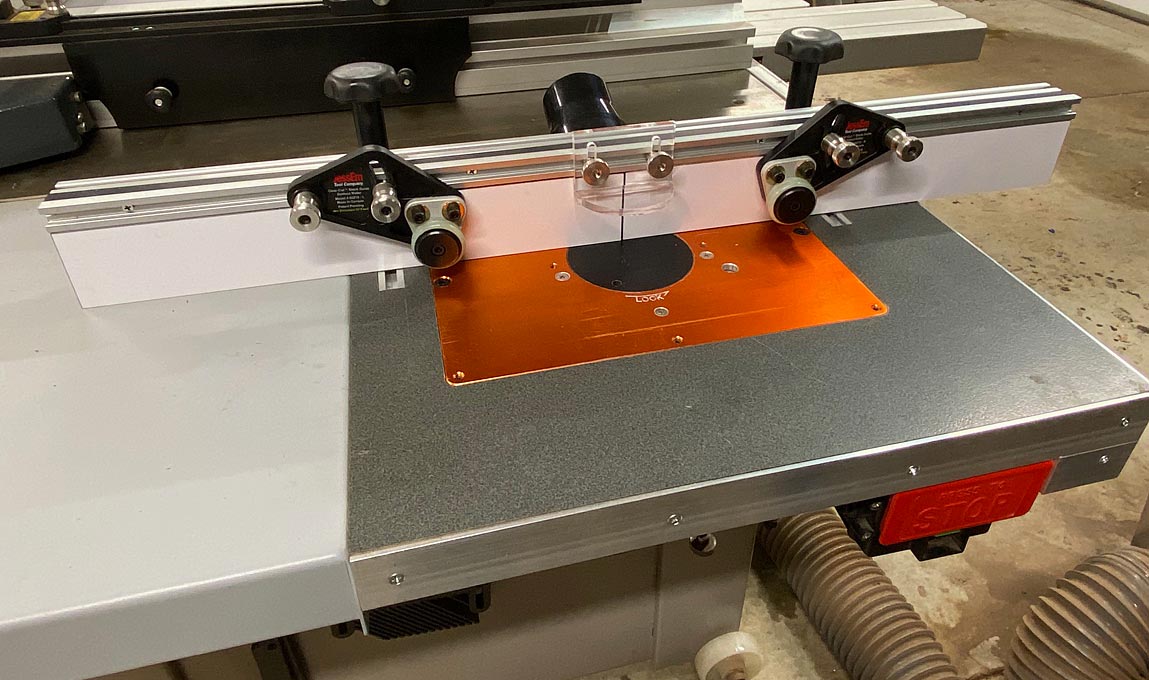

I built a router table into the outfeed ...

Built the fence as well ...

So, in effect, there are two small combination machines rather than one large combo. My machines do not need to move, but do have the Hammer wheels (not great) - I would plan to add a custom trolley if moving was necessary.

Lastly, Chris is correct when he says dust collection is not an option. I am getting by with a 2 hp Carbatec model and 5" hoses. Barely. I plan to upgrade when I can.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

9th October 2022, 06:32 PM #115

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- May 2013

- Location

- Auckland, New Zealand

- Posts

- 997

Matt, do you really need a panel saw? what about smaller sliding panel saw say the likes of Nova SI300? 1600 sliding /1270 ripping.

nova si300s.JPG

this paired with a combination machine would be perfect..

nova fs410.JPG

However, if ACM makes smaller version sliding table bandsaw I would've suggested it rather than sliding panel saw... panel saw and bandsaw in one!

acm sliding.JPGSCM L'Invincibile si X, SCM L'Invincibile S7, SCM TI 145EP, SCM Sandya Win 630, Masterwood OMB1V, Meber 600, Delta RJ42, Nederman S750, Chicago Pneumatics CPRS10500, Ceccato CDX12

-

9th October 2022, 09:14 PM #116

Member

Member

- Join Date

- Dec 2015

- Location

- Melbourne

- Posts

- 56

-

8th February 2023, 06:45 PM #117

Iím picking up a hammer c3 31 combo and bandsaw unit soon! Iíve owned the same combo basic unit before but this time itís a comfort package with the outfeed slider and number of other options plus the N4400 bandsaw.

Now have a tablesaw and combo jointer unit to sell before the new machine arrives

Should be armed for the upcoming house cabinetry projects

Cheers

Nathan

-

8th February 2023, 07:23 PM #118

Member

Member

- Join Date

- Dec 2015

- Location

- Melbourne

- Posts

- 56

Pm me Nathan! Where are you and let me know about combo and saw! MAt

-

8th February 2023, 09:15 PM #119

-

15th February 2023, 04:26 PM #120

New Member

New Member

- Join Date

- Mar 2019

- Location

- Hawthorn

- Posts

- 3

Mat

I have a similar space to what you have: 4.7 x 4.2m, similar length, a metre wider. I have a similar set of machines to what you are planning (all mobile) and I am currently in the process of replacing a table saw with a sliding table saw.

If you are still deliberating about how to fit things into your space, you are welcome to visit and get an idea of how the machines might fit in real life. I am in Melbourne (Hawthorn). PM me if that would help.

John

Similar Threads

-

Combination Machine

By Dewfurn in forum WOODWORK - GENERALReplies: 7Last Post: 22nd August 2004, 09:11 PM -

Which Five Combination Machine?

By gazallo2003 in forum TABLE SAWS & COMBINATIONSReplies: 13Last Post: 15th December 2003, 12:50 PM

Thanks:

Thanks:  Likes:

Likes:  Needs Pictures:

Needs Pictures:

Reply With Quote

Reply With Quote