Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 59

Thread: New table saw

-

25th April 2014, 11:17 PM #31

Mate thats a awesome shop setup. My dusty is pathetic. Period but it gets most of the chips out of the way lol

The extended table slider and fence on the outrigger would be great for sheets. Now I can see all the sheet work your doing look at that garage wall. I thought I had a decent shed size.

Are you running 150mm piping for the dc or 120?

My rig has the tenon option installed just no cutters. Ive been in contact with the hammer rep regarding the cutters but I just havent done anything about it as were going to be doing major reno on our house later this year.

I love the spiral cutter. I jumped from a dewalt thicknesser that sounded like a harley Davidson and carbatech 6" jointer the had a fair bit chipout or snipe. The spiral head is so smooth. I got the cleaning kit thst has the 10 extra blades so should last me a long time. Mine is the single phase 20amp 3 x 4HP model . I have taken out my spindle moulder as I intend on buying the sanding kit for it as I would use it more than my moulder. I still use my router a lot also the digi handwheel for thicknesser would be a great addition.

I need to build some shelving so I can store all the accesories like rip fence and outfeed extensions and other hesvy accesories as they are large and csnt just sit them on the side of the machine like my old contractors saw.

Shame your on otherside of country would be good to see the rig in use and your workshop

Certainly a huge upgrade over the triton!

-

25th April 2014 11:17 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

26th April 2014, 01:33 PM #32

Senior Member

Senior Member

- Join Date

- Dec 2004

- Location

- Perth

- Posts

- 324

Ahh reno's on houses. This sort of gear looks crazy expensive until you start looking at your mortgage. Then it seems very reasonable

The shed's not as big as it looks, still only 6m*6m but still feel very lucky to have it. Things got a little bit outta control in the design phase hence the domed plywood ceiling. That's the drama with having big ideas and ordering plywood when you're drunk. You have to sober up and build it at some stage.

Running 150mm solid then dropping down to the standard 120mm for the flexi at this stage. I was a bit disappointed that inside the machine the 120mm drops to 100mm for the saw inside the cabinet. When I get a chance I'm going to put a 120mm Y inside the machine with 100mm to the catcher for the saw and a free 100mm inside the cabinet. It gets pretty full of chips when using the dado.

I looked at the sander option for the spindle moulder but it was stupidly overpriced. By the time you bought the shaft extension and 1 of the 3 sizes of sanding drum you were up at the same price as a cheap standalone oscillating bobbin sander with 5 sizes of drum. You'd still be stuck without oscillations on the spindle moulder sander which I reckon would lead to uneven sanding and gouging. That's what annoys me about Hammer/Felder. Some of the big stuff is perfectly reasonable in price and some of the simple stuff is so stupidly priced it's cost prohibitive.

Now what is nice for the spindle moulder is a spiral head cutter and guide ring.

Knock up a curve template out of mdf, rough out the shape on a bandsaw (or with a jigsaw ), clamp the wood onto your template and run it through this. The most gorgeous long arcing curves with the same finish on the face as you get off your spiral head thicknesser. Think it was about $300 plus a bit extra for the guide ring and bearing.

The handwheel and readout is a must for the combi machine I reckon. Takes the guesswork out of repeating sizes when you're thicknessing if you stuff something up and need another piece after you've changed back to another mode. I've gotta say, I've found the swapping between modes to be a non issue. It'd be nice to have all separate machines but I'd prefer the space to be honest. If anything, I reckon it's helped my workflow because I actually plan all my steps at the start now.

I reckon if you could swing a sheet onto a sawhorse to rough cut it, you could put it on the sliding table.

I have the sheets stacked up by the door, pivot them up on the 4ft end and see saw it up onto the slider. When it's up there I put a triton multistand under the free corner and slide it around to the crosscut stop and pull the clamp down. No lifting of the sheet involved. The long table is great for getting a straight edge on recycled timber as well (which is what I mostly use).

-

26th April 2014, 04:43 PM #33

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

No way can I get a full sheet on saw horses, been there and tried that. I put some 4 x 2 timber on the floor and drop the sheet on that and use a home made saw guide to cut it in half. 19mm MDF weighs a lot more than I am willing to try and manhandle in one sheet. If I was a lot taller and a lot younger I would give it a go but not now.

I never gave the Dado debris a thought before you mentioned it. Just how do they expect the debris to be collected? I will get another port and cut it into the cabinet and integrate a blast gate into it before I use the dado. I too was a bit P"d off to find a 100mm flex inside the cabinet, cheapskates springs to mind. Cutting 1200 x 1200 on the slider without the outrigger is no issue and I reckon a 2400 x 2400 could be broken down that way with two people but why would anyone bother unless you were really pushed for room.CHRIS

-

27th April 2014, 11:08 AM #34

[QUOTE=dalejw;1769038]Ahh reno's on houses. This sort of gear looks crazy expensive until you start looking at your mortgage. Then it seems very reasonable

Well i didnt buy mine brandnew, its a late 2012 model and the guy i bought it from only used it a bunch of times so its pretty much brand new. I got a good price on it but yes your right compared to a house reno its small change lol

Ah okay yeah photos make it look like a warehouse. or that domed roof. Mine is 3m ceilings, 6wideth and 8 long. haha you installed the ply everywhere yourself? including the roof? or the builders do that.?

Yeah thats my thoughts for dust, id run 150 everywhere and then either 150 (if i can cut holes in it) to 120 everywhere else. Yes i noticed that too a few weeks back, i had a side of one of my boxes fall down between the jointer and saw and had to open up where tou change the blades to get it, then found 100m pipe that was all clogged up so yeah id like to change it to 120 internally.

Ah tis funny you say that, i have been contemplating the Triton oscillating bobin sander for aggeeess and then found the hammer sanders. The whole time i have known about the hammer sander ive tried to justify the cost, i mean its just sand paper wrapped around nicely fit cycinders so it seems pretty crazy. Yeah the cutters or blades etc and machinery arent too bad but accessories id prefer to look elsewhere. so so expensive

Man that looks moulder cutter and ring looks awesome, im not doing any curved work but i could imagine tha twould be invaluabel.

Yeah the digi wheel is a must have, Hammer was at the last year sydney wood work show so if they are again this year ill pick it up.

ill invest in a few different blades for the table saw also i think, that dado blade would be amazing, so do you own one of them? what size does yours adjust to?

-

27th April 2014, 11:26 AM #35

Senior Member

Senior Member

- Join Date

- Dec 2004

- Location

- Perth

- Posts

- 324

Just had the brickies put up the walls and a chippy pitch and sheet the roof. I've done the rest. Bending 12mm ply sheets 3.6m up was an interesting experience. Another coupla meters like you've got would be great, it's pretty squeezy but can't whinge. My DC is in it's own little soundproof shed outside and I've got a separate 2.5m * 4m storage shed for crap. It's pretty good to have a workshop with this capability within 4km of the perth CBD. Location should help when I get around to commissioned pieces when this reno is done. Also the reason it's a ridiculously flashy shed, it's going to have to act as a showroom as well.

The dado set does 8 -19.5mm and is 8" diameter. Spewing the Felder set doesn't fit in this machine. It's a 10" and does up to 21mm I think. It's only $100 more as well for the extra capacity. I looked at other dado sets but the Hammer set was so far ahead of everything else. The replaceable knives was a big one as I'm going to be doing a load of MDF and ply which eats cutters. I'll put up some pics of the cuts you get from it when I get a chance. It's pretty sweet

-

27th April 2014, 12:26 PM #36

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

The clogging of the internal hoses is caused by either no DE being used or inadequate DE. The Felder saws must have DE attached and used at all times or it simply clogs the lines. It always struck me as short sighted in that the cabinet cannot be hooked up to an extractor, it is only the blade extraction that is hooked up. Mine has got a bit of sawdust in the bottom of the cabinet and there is no practical way of removing it but then it is not a problem. I have had a bit if a problem at times with long thin cut offs going into the blade extractor and staying there and I have had to fish them out.

CHRIS

-

27th April 2014, 04:59 PM #37

Yeah thats exactly what clogged mine up was thin offcuts from my mate that owned it before me. Once i got them out it hasnt clogged up. i only have a small 1HP dusty as it was all i could gget at the time. I intend to buy clearvue ultimately but im still not sure if i should just put up with the 1hp (as it does chip collection ok) or get a 2HPto fill me in until i get the clearvue. Anyway ive spoke about it in the DC sub forum so ill leave that for there. But yes the cabinet of mine actually had inches of dust collected in mine but its all cleared out now.

I thought i read in the manual that the C3 31 can only handle a 6" dado? i must have read wrong, or when Hammer ask if you want the dado option added on are there multiple types? From looking at the blade attached to arbor there doesnt seem to be blade housing restricting the size of the dado either 6 or 8" so i would be suprised if it can actually only do 6".. hmm i should re-read that part of the manual . Yeah i have read a lot of positive reviews about the hamer dado stack over the forrest on other forums. It sure does look nice, would love to see photos of how it clears out the trnech and if its flat or a bit grooved.

im just making more jigs for my saw to help me with box making and smaller stuff at the moment. My workshop is Brick / concrete slab, i really want to sheet it with fairly thick ply and use some form of epoxy resin on the slab as im sick of dynabolting and masonry drilling, id prefer to wall mount stuff to ply and replace the sheet one day if need be. dont want to keep poking holes in the brick. Maybe ill do it when the house is under reno later this year as its a fairly low cost thing to do to improve my workshop. Ill be putting some of my old kitchen cabinets on the wall also for storage.

I think my routine of squaring up stock has been improved since ive owned this machine also, the fact i need to change DC and transofmr the thing means i want to minimise it so i think about all the stock i need in advance and get it all to the size i need unlike before walking all around the workshop. Im only a hobbiest i dont know the most efficient methods like a pro . It will certainly stay in my family. ill buy more accessories for it but i dont intend on "upgrading" from this combo machine.

. It will certainly stay in my family. ill buy more accessories for it but i dont intend on "upgrading" from this combo machine.

What do you do for a crust Dale?

Did either of you purchase a different Rip fence or is it the standard one?

-

27th April 2014, 06:21 PM #38

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

I purchased the accessory fence with the fine adjuster on as well as the Dado capability. Another thing I have to attack is the overhead DE. I think I will hook up a dedicated vacuum cleaner to that and put the VC in a box above the machine and I will vent that box with the Clearvue to prevent the fine dust spreading through the workshop. My thoughts are to modify the VC so it vents straight through and into the CV by ripping out the bag. Plans and reality might be two different thing though and I have to decide on what VC to use. I am hoping I can ditch the canister part of the VC and mount that on something else so it spits the dust straight into the box and the DE extracts it. There will be no bags or filters on the VC that way so it can be mounted up near the ducting for the DE.

CHRIS

-

27th April 2014, 09:50 PM #39

Senior Member

Senior Member

- Join Date

- Dec 2004

- Location

- Perth

- Posts

- 324

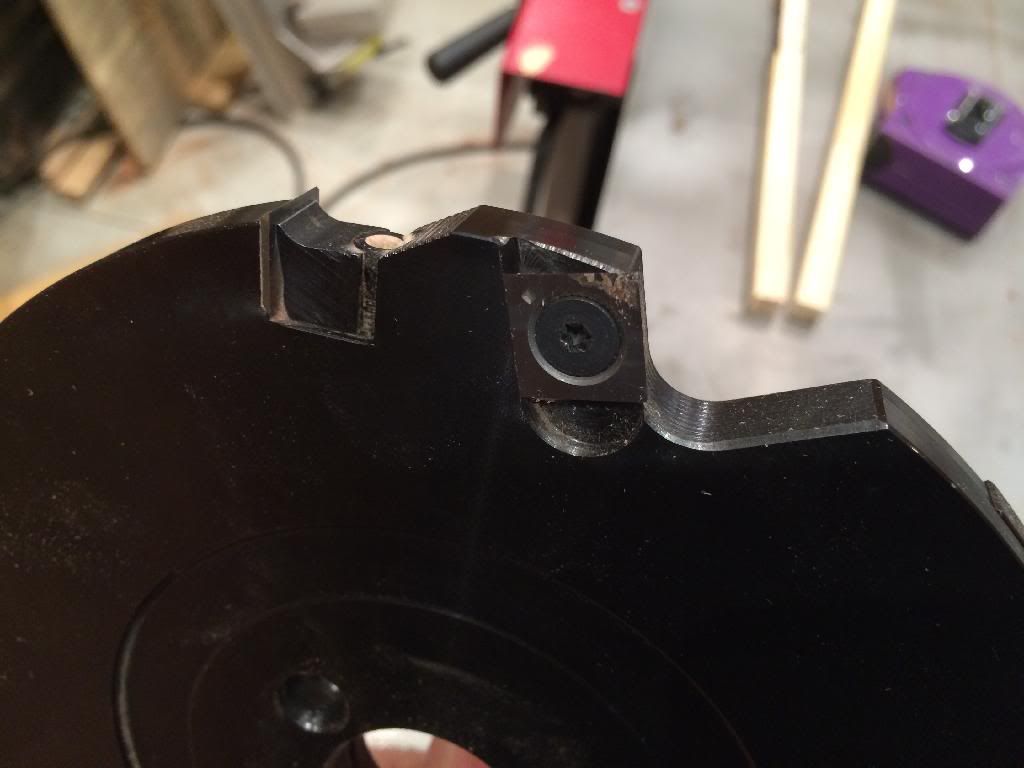

My mistake, the Hammer dado blade is a 180mm. The Felder is 228mm but it doesn't fit. This is an old test piece that I've had around for ages so the shoulders have chipped (but that wasn't the dado blade) but you get the idea.

It's stunning really, I can't imagine how you could get much better.

I'm on the standard rip fence which I'm not super stoked with. Pretty unwieldy. Wouldn't mind a pic of your rip fence Chris if you've got the time. It's a definite weak point.

I can recommend the ply on the walls. It's great to be able to put stuff up wherever you want. Mine's single brick and I attached 5 horizontal 35*70 battens to each wall with masonry anchors, put a layer of sarking on and then nailed vertical joists to the battens like so.

Also stuffed the walls with batts before the ply went on. Very even temperature and quiet on the outside.

-

27th April 2014, 11:37 PM #40

That is a nice trench cut! nice and clean, very nice. So does it adjust via shims or something on the other side of the side shown in the photo? Looks to be worth its price for sure!

I have this fence,

20140427_212748.jpg

20140427_212727.jpg

It is dead straight and heavy so i know it sturdy, i have the micro adjustment on it also which is ok, dont mind it.

The thing i dont like about the rip fence is this thing!, It has bent once or twice because if you dont remember to watch for it it can get bent when you take if off and sit it elsewhere. Its Pretty heavy to move around as it doesnt "slide" like any other table saw biesemeyer fence i have used in the past. so repeatable cuts is a bit of a PITA, its do able but yeah certainly doesnt have any thread lock system like my friends incra system has. Shame there isnt some Incra retrofit that could be engineered for a combo machine

20140427_212742.jpg

i found a larger rip fence in the hammer catolog with a different mounting pole etc but it wasnt on a combination machine, possibly it was the K3 i saw it on so think im stuch with this for my machine. Aparently theres a digital read out from hammer that works wonders? Plus Chris just mention before he was thinking of puttin a wixey on. That might work for the K3 as the rip fence might not be pulled off the machine completely as much as it would on mine. i fear i would be spending more time calibrating the fence rather than how i do it my eye and measuring now.

-

28th April 2014, 10:40 AM #41

Senior Member

Senior Member

- Join Date

- Dec 2004

- Location

- Perth

- Posts

- 324

Wholly crap, I didn't know there was a microadjust available for the fence. I'm going to have to order that today. Does the fence move much when you lock it with the big knob?

Mine can move up to 1mm as it's locked which makes it a pain to adjust. Hopefully the microadjust will stop that. I don't think I'm going to go the wixey route. The way the whole fence mount swings out of the way makes me think it would be prone to damage as well.

That little aluminium tag bends on mine as well. Waiting for it to snap as I'm bending it back. Not sure why they couldn't have put a little window with a hairline like the crosscut fence. That would have been nice.

The dado set consists of 3 cutterblocks. 2 with shims gives you 8mm-15mm and then you replace one of the cutter blocks with a wider one to do 15mm-19.5mm. It's very easy to set up to be super accurate (0.1mm). Still unsure if it's good value... Dunno if any saw blade that costs over a grand can ever be value but it is good It'll also never wear out with the replacable blades.

It'll also never wear out with the replacable blades.

-

28th April 2014, 11:22 AM #42

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2005

- Location

- Helensburgh

- Posts

- 7,696

The micro adjustable fence has a round bar to slide on and a user in the US has added a Wixey to it with no interference issues. He did say he would send me some pics but they never arrived. It was a very neat installation and I am about to go down to the workshop and look at doing mine. Found it, micro fence with Wixey http://festoolownersgroup.com/index....ch=50327;image

The micro adjustable fence does not move at all when it is locked. It has two locks, the primary one locks the main head but release the micro lock and it allows the adjuster to incrementally move the fence within about a 50mm range in total. In that photo you can see the main locking lever with the smaller micro lock knob beside it. One good thing about the round bar is if you want the table clear to cut something using the slider it just swings around the bar and the fence finishes up vertical and this saves removing it.CHRIS

-

28th April 2014, 03:26 PM #43

No not at all, its really tight. the micro adjuster is good but i still measure inbetween the blade and fence for repeat cuts just to be sure.

Yes i totally agree, the clear perspex with red needle line on the flip stop on crosscut fence is super accurate. i love it. if they had a similar thing for the rip fence would be amazing. shame!

VERY nice!, all your accessories are pretty much what im aiming to put onto mine. But i still get heaps of work done even on my current configuration, they are just nice to have things for me. ill get them soon enough

-

28th April 2014, 04:37 PM #44

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- Perth

- Age

- 45

- Posts

- 106

Excuse me while I wipe the drool off my keyboard. Both the shed and the saws (your's and the OP's) are making me insanely green with envy. Your 2.5m x 4m crap storage shed is the size of my whole "shop".

Sorry I have nothing further to add to the conversation, just had to get that out. As you were gentlemen.Michael

-

28th April 2014, 08:55 PM #45

Here is the rest of my "workshop" I have a Woodfast V1000 lathe, Jet bandsaw. Im rebuilding my router table top as its crap and im building a new one gifkins style.Hammer C3 31 and a small dusty. heaps of hand tools and pen making accessories. Timber storage etc. but i want to rip all of this down so i can put ply on the walls and epoxy the floor. Tried rotating photos but .....fail

Mine may be a little larger than yours Dale but mines full of stuff haha

DSCF0191.jpgDSCF0190.jpgDSCF0189.jpg

Similar Threads

-

Sliding table and out-feed table for TSC-10HB table saw

By mikm in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 31Last Post: 24th July 2009, 12:58 AM -

Sturdee’s collapsible sheet cutting table & extra workbench/assembly table.

By Sturdee in forum THE WORK BENCHReplies: 7Last Post: 13th November 2008, 07:53 PM -

What's The Difference Between A Pool Table & Snooker Table & Billiard Table

By echnidna in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 47Last Post: 26th January 2007, 05:09 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote