Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 10 of 10

Thread: Table saw position advice

-

25th April 2010, 10:53 AM #1

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- Southern Riverina

- Posts

- 139

Table saw position advice

Table saw position advice

I'm picking up my new (well, s/h) table saw this weekend and being a tablesaw newb I'm not sure exactly how I should position it in the workshop.

Both the workshop and the saw are relatively large, but I'm not sure I want it right in the middle of the floor. It's a 12" right-tilt cabinet with a swinging arm slider on the left. I may need to lose the slider and/or sacrifice full-sheet capability but it would be nice not to. I'd also like to not have to step over the dust pipe.

I think the general orientation of my shop and the location of the door and the extractor is making things tricky. Is it practical to have the far end of the outfeed table butted up against a wall? That way I could run the dust pipe under it and remove the swing arm when I need more floor space to the left of the saw. Any other tips on locating a ts near a wall?

I'll see if I can draw up a plan...

-

25th April 2010 10:53 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

25th April 2010, 11:34 AM #2

I put mine with the right hand side of the machine near the wall. That way you can still feed long bits through, and the slider is free to move, for when its needed.

-

25th April 2010, 11:36 AM #3

One mistake I made (and am about to correct) is setting the saw up for working with smaller pieces only.

I'm just starting a job for someone that requires 3m long rails, which I can't get onto (or off) the saw without hitting a wall.

Make sure your infeed/outfeed line up with the doors of the shed !!

-

25th April 2010, 12:51 PM #4

Senior Member

Senior Member

- Join Date

- Dec 2008

- Location

- Tasmania

- Posts

- 430

Hi Dusty Dave,

Have a think about positioning your saw right at the door (assuming you have roller door or tilt door) such that the sliding table just clears the door in its retracted position. Then when you are cutting sheets half the total length required for this function will be outside your shed. This is what I've done and it gives me heaps more room to work in. It is s little tricky when its raining but that's not very often in the part of Tassie I live in.

Cheers Old Pete

-

25th April 2010, 01:57 PM #5

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- Southern Riverina

- Posts

- 139

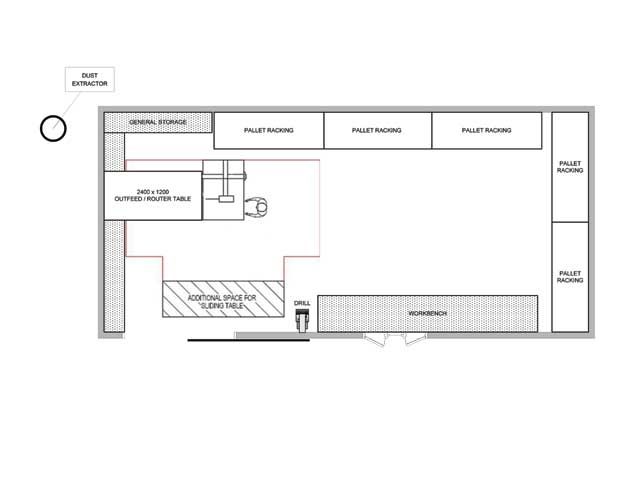

Thanks for the replies, I had a bash at it with Visio and this is what I've come up with:

Let's call this plan A (the red outline is from a diagram on MWE's site for their MBS-300 - I'm surprised how much space the sliding table needs!) Hopefully in this configuration the table can live at it it's 'furthest' position towards the wall when not in use, and that way leave the entrance mostly clear without having to remove the slider. I don't know how much work is involved in removing and refitting the slider, but I guess it's better avoided if possible?!

(FWIW the ceiling is higher at the back wall so I'd prefer to keep the pallet racking there if poss, although I can move/reduce it if necessary).

The only other option I can think of (plan B) is to flip the saw through 180 degrees and have it closer to the bottom wall like Ironwood's suggestion, with the outfeed table in front of the window. It's probably a better location but for the dust extraction - the pipe would have to go across the floor or the roof - something like 9 metres as the crow flies plus rise and fall.

The extractor location shown is in a chicken coop which is protected from the weather and away from my lungs so it seems ideal for the job. I only have a GMC 750w extractor though, so I doubt it will perform well over a long run - therefore plan B would probably mean building a new structure for the extractor, buying a new extractor, or both.

I'll see if I can draw up plan B anyway just for the fun of it.

Any other ideas?

-

25th April 2010, 02:07 PM #6

Dave, if you are over my way feel free to drop in for a peek at my setup. I can run a full sheet in a crowded small shop by setting all the bench heights the same so the sheets can 'fly' over them by 1mm.

Your setup looks good. It is best if you have the entrance in your peripheral vision so no-one can walk up behind you and tap you on the shoulder when making cuts on the saw

You can also stow the swing arm on the slider out of the way quite well when not in use.

-

25th April 2010, 02:13 PM #7

You have a nice doorway there, why not utilise it? You can position the saw so the panel outfeeds through the doorway or the swing arm on the slider goes out the door. That frees up more room in the shop.

-

25th April 2010, 03:48 PM #8

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- Southern Riverina

- Posts

- 139

I thought about that, but the truth is I'm not so much a 'woodworker' as a general DIY hack. The rest of the workshop is fair game for having specific functions, but I really need to keep that main area inside the door clear as it is the most useful space for things like welding and auto repair. Even plan A is less than ideal in this regard but considering the dust extractor I suspect it might be the best compromise.

On the subject of dust extraction, does anyone have any simple (and preferably cheap) solutions to the problem of protecting an extractor from the weather? Plan B would mean putting it on a very exposed wall:

-

28th April 2010, 01:33 PM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2007

- Location

- melbourne australia

- Posts

- 2,643

Dave,

I once had a quite elaborate dust extraction setup in a previous workshop. It had rigid ducts, flexible ducts, blast gates, etc. It was a mess to be honest. My current workshop has a dust extractor on castors and one 4m flexible duct. When I'm cutting, jointing or thicknessing I wheel the extractor outside and close the roller door on the duct. That keeps the noise and fine dust outside. When I'm done I bring the extractor in again. When I switch machines it only takes a few seconds to swap the hose over. I'd never go back to a plumbed-in system.

I wired up a switched socket to plug the extractor into via an extension lead. I have a 20A rotary switch suspended above the combination machine so I don't have to go outside to switch the extractor on and off. Best mod I ever did in my workshop.

Cheers

-

29th April 2010, 05:25 PM #10

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- Southern Riverina

- Posts

- 139

Thanks Jack, you make a good point - it's tempting to over-complicate things.

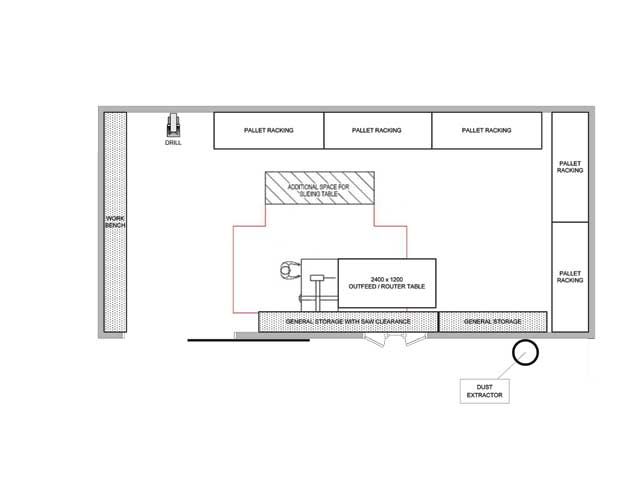

I've decided to go with plan B. For now I'll just wheel the DC outside, but ultimately I'd like to find a permanent spot for it. With a bit of ingenuity I think I can probably get it right next to the machine and still allow the sliding door to open.

Thanks again for all the tips.

Similar Threads

-

In a position to help 12 forumites!

By SWR in forum TIMBER & WORKING WITH WOOD SHOWSReplies: 5Last Post: 15th June 2008, 12:08 PM -

Where to position the lathe

By jefferson in forum WOODTURNING - GENERALReplies: 9Last Post: 11th May 2008, 01:07 AM -

Insert position in table top

By greenie512 in forum ROUTING FORUMReplies: 2Last Post: 22nd July 2007, 10:11 AM

Reply With Quote

Reply With Quote