Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 75 of 99

Thread: Two new machines to restore

-

20th June 2007, 09:59 AM #61

Brilliant work. Excellent thread.

Reality is no background music.

Cheers John

-

20th June 2007 09:59 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

20th June 2007, 03:17 PM #62

Jeff,

Man of many talents. We too often have problems with 3 phase to domestic premises and our authorities take a dim view (read illegal) of electrical work being carried out without a ticket. Can't wait to here how the jointer performs.

Cheers MikeMike

"Working to a rigidly defined method of doubt and uncertainty"

-

20th June 2007, 03:49 PM #63

Hi Jeff,

We do have 3 phase and it is generally available for home use but you have to pay a fair bit to have it connected and they generally require a good reason.

I'm interested in your RPC. Any chance of emailing a schematic or similar?

Great thread by the way and nice job on the motor refurb.

Tony

-

20th June 2007, 09:58 PM #64

-

21st June 2007, 01:59 PM #65

I am going to put the plan on my web site shortly. The design belongs to Bruce and he just asked that I wait till we prove the design before making it public. Obviously it works but still need to actually fire up a motor on it and see how that runs. If no problems there I will then add it to my web site. Along with his plans for a 5hp unit.

JeffJeff

When we remember we are all mad, the mysteries disappear and life stands explained.

- Mark Twain

Excelsior Woodworks My little space on the web

-

21st June 2007, 05:05 PM #66

Thanks Jeff,

Will keep an eye on your site.

Tony

-

21st June 2007, 07:39 PM #67

Hi Jeff,

Came across your thread yesterday, and must say, (as others have)what a great thread, very interesting. Am impressed at the scale of your project and the grand results. Well done indeed and well explained and lots of photos, terrific.

I have an old bandsaw, secondhand, (or maybe twenty secondhand) and have been putting off the resoration job, just looked too daunting, about the same condition as you BS was in. But now I see it can be done.

So thank you very much for sharing and providing some inspiration and motivation. Do keep us up to date, can't wait to see the sawdust you will make.

Cheers

Pops

-

26th June 2007, 02:31 PM #68

I am finally back to work on the Great Pumpkin. Hoping it will make some chips in the next few weeks. The list of things-to-do is actually very short. The motor has been the main hold up. That and getting 3 phase power in the shop. The motor is is done and sitting in place.. well sort of. Gives me a chance to eye-ball it for a few days to decide how I want to mount it.

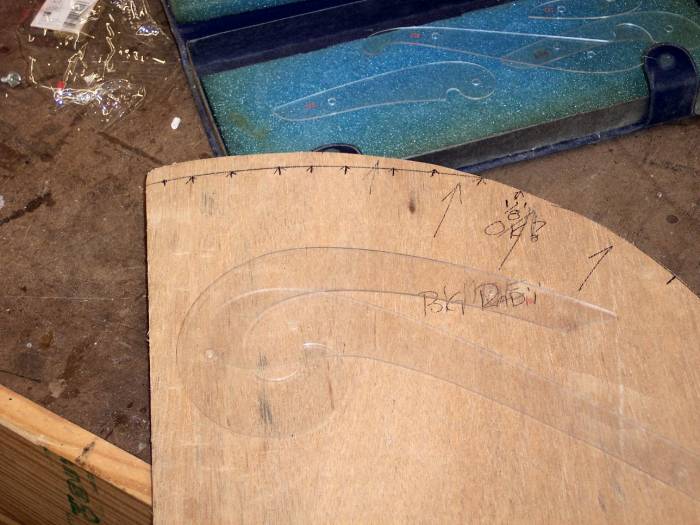

Tonight, despite the fact this heat is just wearing me out, I made myself go to the Lab and do some work. (just realized it's winter down under! Summer here and a hot one!) I decided to play with paper dolls and try to make a blade guard. Since I am keeping the square head the guard is not an option, it is a must!

I made a couple of cardboard dollies and found one that the design looked good So I graduated to luan dollies.

This one looks pretty promising. I have a hole in the table that I assume was for a pressure bar when doing moldings? It's in an excellent place for the guard and even had a thread hole for a set screw.

I have a small gap present when I run a narrow strip through there. I may try one more and try making the radius larger and see if that helps close that gap. Even so, it's pretty small and wouldn't be easy to stick a finger in there. And I plan on using push blocks all the time!

I didn't allow for a method of holding the guard in place. That will be either an extension spring or a counter weight. I am giving serious consideration to a counter weight just because they are old school (and simple). But the spring is simple and nothing to go wrong with it except if it breaks.

JeffJeff

When we remember we are all mad, the mysteries disappear and life stands explained.

- Mark Twain

Excelsior Woodworks My little space on the web

-

26th June 2007, 02:42 PM #69

-

28th June 2007, 06:31 AM #70

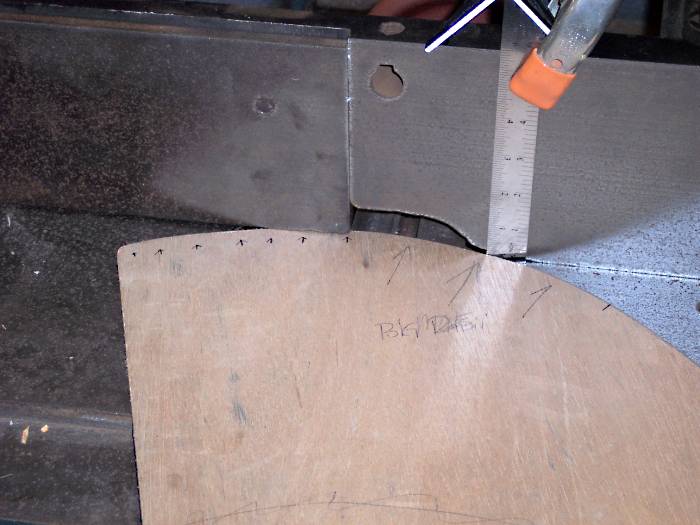

Got to give credit to Jeff Smith for this idea. I was all around it and just couldn't figure out a good way to get the curve right on the guard. Jeff said something about sliding it under the fence and marking it, then it clicked with me! Thanks Jeff!

Mounted a an old scale (ruler) to have a constant reference point for the guard to register on. I would slide the fence up and make a mark till I was about 3/4" or the way across the table.

Cleaned up the lines with French Curve set. Cut it out and cleaned it up on the sander.

It didn't turn out perfect but it was close. I had to trim and modify it just a bit here and there. But it made a very close starting point. I am very happy with the end results. The pesky gap I had is all but gone now.

I need to extend the edge closest to the operator a 1/2" and it will be ready to build a real one. Still have not decided on the material but leaning toward someones suggestion of a nice piece of wood and brass rub rail.

Now on to the motor mounting.Jeff

When we remember we are all mad, the mysteries disappear and life stands explained.

- Mark Twain

Excelsior Woodworks My little space on the web

-

28th June 2007, 11:09 PM #71

What an awesome thread.Even swmbo was (slightly) impressed.

Well done. Have a greenie. Cheers

Cheers

Jim

"I see dumb peope!"

-

29th June 2007, 04:35 AM #72

Jeff

Jeff

When we remember we are all mad, the mysteries disappear and life stands explained.

- Mark Twain

Excelsior Woodworks My little space on the web

-

30th June 2007, 11:05 AM #73

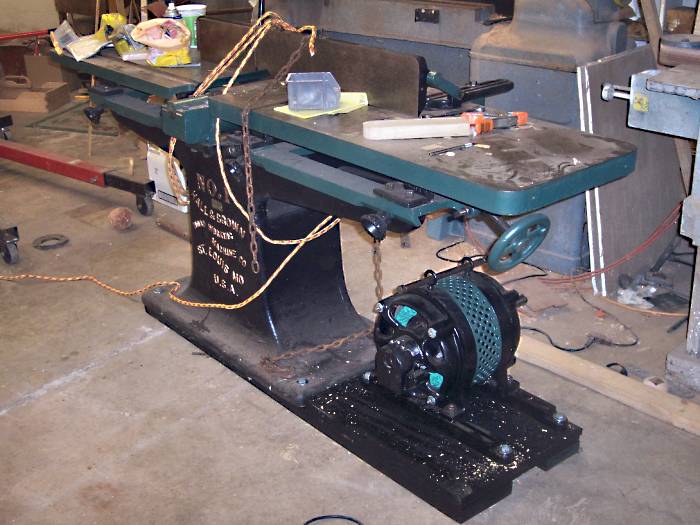

Finished up the motor mount today. Time to start looking for a flat belt and working on the wiring. It's getting REALLY close to lighting the fuse on this rocket!!

I looked into flat belt prices and was floored! Leather is about $22 a foot! So pursuing all the options.

The machine is not heavy enough I can just BARELY move it by myself. I was able to scoot it across the floor but it's all I can do to move one end now.

I think I may pick up the conduit and start pulling the 3 phase power across the shop.

Looking at these photos I really need to sweep the floor and tidy up.

JeffJeff

When we remember we are all mad, the mysteries disappear and life stands explained.

- Mark Twain

Excelsior Woodworks My little space on the web

-

30th June 2007, 12:09 PM #74

G'day Kudzu,

So the motor just sits on it's own bed on the floor, I thought it might be housed somehwere in the stand - well there you go.

It's going to be like turing on the green Frakenstein when you get the power sorted out. Must be mixed feelings coming to the end of this restoration.

-

30th June 2007, 11:22 PM #75

This machine never had a motor. Well not when it was new that is. It was driven from over head off of a line shaft. It maybe have been converted to an electric motor somewhere along the way but I don't know any history on it.

I have it's twin sitting on a trailer waiting to be delivered to it's new owner and then cut a metal plate and bolted it to the side of the main casting. Very ugly to my eyes. I thought for a while and this was the simplest way to get a motor on there and not drill holes in the machine.

As for coming to the end of a restoration, I look forward to it. That means I get to use it!! And even though I enjoy restoring these, I would rather be making sawdust!!Jeff

When we remember we are all mad, the mysteries disappear and life stands explained.

- Mark Twain

Excelsior Woodworks My little space on the web

Similar Threads

-

Mortising machines

By sinjin1111 in forum HAND TOOLS - POWEREDReplies: 36Last Post: 11th May 2009, 10:29 PM -

Badge engineering - Rebadging identical machines

By boban in forum HAND TOOLS - POWEREDReplies: 53Last Post: 18th January 2008, 02:44 AM -

System restore trouble again

By jow104 in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 7Last Post: 28th August 2006, 07:39 PM -

Various types of GMAW machines

By Grahame Collins in forum WELDINGReplies: 0Last Post: 24th December 2005, 10:22 PM -

combination machines

By stevepay in forum TABLE SAWS & COMBINATIONSReplies: 5Last Post: 2nd August 2003, 12:21 AM

Reply With Quote

Reply With Quote