Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 31

-

13th March 2014, 09:42 AM #16

This should give you a good understanding of whats what:

http://www.caswellplating.com/buffs/images/Buffbook.pdf

You haven't thought about diamond wheels …..Live a Quiet Life & Work with your Hands

…..Live a Quiet Life & Work with your Hands

-

13th March 2014 09:42 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

13th March 2014, 09:46 AM #17

-

13th March 2014, 11:21 AM #18

I've just had a look through Caswell's site, and they have also got a branch in Oz. Some of their products are actually made here.

$5.49 in the USA, so about $6 Aussie but only 20 folds

$22.95 from Australia has 50 folds

Post edited to fix incorrect link, and corrections.

-

13th March 2014, 02:36 PM #19

Get your facts right or shutup.

Get your facts right or shutup.

The Canton Flannel Wheel 8" x 1/2" offered in Australia by Caswell (and put up as your example of Taxes gone wild etc) at $22.95 are 200mm x 25mm ie 50 layers of cloth instead of the 20 layers in USA so get it right before you start your regular sheeitcanning of Australian prices.

For that matter leave pricing out of it all together.

http://www.caswellplating.com.au/sto...l-wheel-200-mm

Neil

-

13th March 2014, 04:14 PM #20

My apologies, I've edited that post. When I looked at the Aust.website before I couldn't see any mention of the thickness, which is why I put the caveat "One thing is not clear: the Aussie one is "50 folds" but no thickness specified, the USA made one is ½" thick but no folds specified."

There was an incorrect link in the post too, which has been corrected.

50 folds verses 20 certainly makes them much closer in price, and well worthwhile purchasing locally.

-

13th March 2014, 08:31 PM #21

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

I'm not sure this is the case. Diamond wheels are very big in the Lapidary world and are dirt cheap.

SWMBO buys 8"diamond wheels in a range of grit sizes (60, 80, 100, 150, 240, 320, 500, 600, 800, 1200, 1500, 3000) for ~$20ea and uses the on her variable speed lapping machine.

eg http://www.ebay.com/itm/8-INCH-Grit-...-/121116982171

In fact I just tried it it out on a lathe tool and it worked a treat.

Very cool grind.

Guess what I'm using from now on.

Now why haven't these been thought of before?

-

13th March 2014, 09:10 PM #22

Senior Member

Senior Member

- Join Date

- Feb 2012

- Location

- Sydney

- Posts

- 187

Another good lapidary tool is the expanding wheels that go on the grinder. They take a belt and when the grinder is brought uo to speed the wheel expands and grips the belt. They act like a easy change grit wheel

-

14th March 2014, 12:43 AM #23

It clearly states thicknesses on the link I put up and you have now changed to:My apologies, I've edited that post. When I looked at the Aust.website before I couldn't see any mention of the thickness, which is why I put the caveat "One thing is not clear: the Aussie one is "50 folds" but no thickness specified, the USA made one is ½" thick but no folds specified."

It clearly states thicknesses on the link I put up and you have now changed to:My apologies, I've edited that post. When I looked at the Aust.website before I couldn't see any mention of the thickness, which is why I put the caveat "One thing is not clear: the Aussie one is "50 folds" but no thickness specified, the USA made one is ½" thick but no folds specified."

Directly below the picture is the following:

200 mm diameter, 25mm thick Canton Flannel Wheel with 12mm centre hole.

and lower down the page it says:

Other Standard Sizes Available

Small 100mm x 25mm [4" x 1"]

Medium 150mm x 25mm [6" x 1"]

Like I said before Brett get it right or don't bother posting at all.

-

14th March 2014, 08:28 AM #24

I was specifically referring to Diamond Wheels for bench grinders which are apparently very expensive. Couldn't find any of them on eBay either (in the right width of 25mm +). I did find some here, and they also have the sintered version (longer lasting, but exxy)

Those lapping discs you found are as cheap as chips (as is the Diamond Paste, which I use). I wonder how "flat" they are? That is, suitable for lapping the backs of chisels and plane blades or not.

Was the turning tool that you sharpened a flat bevel or curved? For chisel and plane bevels you'd need a device that would ensure repeatability of the bevel angle (but the actual angle wouldn't need to be critically exactly 30° or whatever (i.e. ~29-31° is plenty close enough), just as long as it can be repeated exactly. Perhaps they can be fitted to a Worksharp 3000 or similar (depending on the hole size). Even on the sanding disc of the Multi-tool linisher, but you'd have to find a way to put them on (stick a sheet of Velcro on, but that probably wouldn't be flat enough).

-

14th March 2014, 04:40 PM #25

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

I put my best ruler on them and they look pretty good but I will have a further play with them when I get a chance.

It was a round nosed scraper.Was the turning tool that you sharpened a flat bevel or curved?

The discs have a 1.2 mm magnetic stainless steel backing plate and are mounted on a 1/4" thick acrylic disc for additional support so they are quite stiff but that could easily be replaced with something much stiffer.For chisel and plane bevels you'd need a device that would ensure repeatability of the bevel angle (but the actual angle wouldn't need to be critically exactly 30° or whatever (i.e. ~29-31° is plenty close enough), just as long as it can be repeated exactly. Perhaps they can be fitted to a Worksharp 3000 or similar (depending on the hole size). Even on the sanding disc of the Multi-tool linisher, but you'd have to find a way to put them on (stick a sheet of Velcro on, but that probably wouldn't be flat enough).

On the lapping machine they are made to be used with water constantly dribbling over them,

The lapping machines supposedly spin from 1600 to 2800 rpm

My point was not to necessarily use these discs as a replacement for anything WW wise but a way of saying that if these can be made this cheap then 8" bench grinder sized wheels of the same stuff should be almost as cheap.

-

14th March 2014, 07:24 PM #26

Well, even if they aren't flat flat, they can certainly do the heavy lifting for flattening backs.

So did you use water (suspect not for a quick touch up), and roughly what rpm was the lathe at?

Indeed. Forgetting the arbor, a 200mm disc has 314 cm² and a 200mm wheel 40mm wide is only 251 cm², so 80% of the diamond surface. Of course the wheel itself is more complex to make than a disc, and more metal. Then throw into the equation the production run numbers...

-

26th October 2014, 04:24 PM #27

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

I'm posting this here because both CBN and diamond wheels were discussed in this thread.

I have since found out that Diamond should not be used on tool steel but does a great job on carbide and VV.

Here is an almost completed variable speed 3 phase grinder with CBN and diamond wheels on one side and a now possibly redundant green wheel on the other.

The grinder is 3/4HP @50 Hx and 3/8HP at 25Hz but as only light touches are needed for both diamond and CBN, power is not an issue.

In case you are interested in more details of of the variable speed 3phase grinder look here.

The Inner wheel is a cheap Chinese 6" 170 grit diamond lapidary wheel.

I used a 6" instead of an 8" diamond wheel as I didn't want the edges of the two wheels to conflict.

The diamond wheel is mounted backed by a 20 mm thick by 75 mm diameter spacer - see photo below.

This helps stiffen the diamond wheel and allows for adequate clearance at the edges.

The spacer has a 5/8" bore to suit the grinder shaft but as the diamond wheel would then be riding on the grinder shaft thread the bore on the diamond wheel has been opened up to 19mm and it rides on a 1 mm raised 19 mm lip turned onto the spacer.

A couple of issues.

Speed must be changed downwards slowly ~5 Hz/s or it will trip out the VFD.

DON'T set up the VFD to apply any breaking as this will loosen the wheels

Still need to make suitable tool rests.

Might make up a bit of a top cover for the wheel as I'd rather not have something hard fall onto the CBN wheel.

-

26th October 2014, 05:27 PM #28

For the first time in some years I have reorganised my grinding/sharpening system. For the past 5 or 6 years I have been using a Tormek 2000 (10" wheel) and Shapton/Sigma ceramic waterstones. The combination is excellent, but I wanted something that did not make as much mess with water - the paste created dries out my hands and I live with cracks.

I also have a half-speed 8" dry grinder with 46 grit Norton 3X and 46 white wheels (which was mainly used for lathe chisels). I long ago stopped using the 3X as it sheds so much grit into the air, which I do not wish to breath in. The white wheel is nearly as bad.

I wanted a dry honing and dustless grinding set up that was fast and efficient. Not much to ask!

About 6 weeks ago I took possession of 4 stone, two diamond (Coarse and Fine Eze-laps in 3"x8") and two ceramic Spyderco (2"x8" Medium and Ultra Fine). The diamond stones are for lapping old blades. The Spydercos are hard and retain their flatness like oilstones, but are worked dry. Spyderco do not say what the grits are, but they are reputed to be 1500-2000 and 6000-8000, respectively.

The search then was on for a new grinding wheel. About 10 days ago I took possession of a 180 grit 1 1/2" wide CBN wheel with 1/4" side radii.

They offer two wheel grits. The 80 grit is indicated for heavy work. From what I could determine, the 180 grit is nearly as fast and provides a smoother finish.

I got mine from D-way in the USA. I liked their presentation and reputation, and Dave Schweitzer answered all my emails promptly and thoroughly. You can find a few of his videos on Youtube. Plus the wheel they sell is 1 1/2" wide compared with the 1" wheel sold locally. I went for the radius edge as I thought it may be more useful, not only for lathe chisels (as they demonstrate), but also for entering and exiting on straight edges. Possibly for hollow blades as well.

David assured me that the CBN wheel will grind all hard steels. With regard laminated blades where there is soft steel, he mentioned that a grind on hard steel will remove any loading, if this occurs.

Installing the wheel is a simple affair. D-way sell a beautifully machined bushing that slipped over the 5/8" arbor on my half-speed grinder. This has a 1 h.p. motor, so is powerful enough to easily push this heavy wheel. It is so well balanced, however, that I imagine a less powerful machine just needs a manual spin to start it along.

The CBN wheel replaced the 3X wheel. The guards were removed - the CBN wheel is solid steel and is not going to blow up! I am use the Tormek BGM-100 set up from before. For more info, go here: http://www.inthewoodshop.com/Woodwor...ngNirvana.html

Is it cost effective? Does it cost too much? Decide for yourself what you can afford. There are lots of ways to spend money on sharpening systems, some of them in my opinion are a waste of time and money, and some of mine are no doubt for others a waste of time and money!

On average I can grind a blade and hone it in just a few minutes. Resharpening takes under one minute. CBN wheel for grinding - to the edge of the blade. It is warmer than a Tormek, but much much faster. The final hollow is slightly deeper. It will last slightly longer. It is important that the edge is smooth and the hollow grind is straight. This means much less work to do in terms of preparing the edge with a coarse stone.

I freehand on the hollow and, after the CBN, shape in a camber on a broken-in Eze-lap Fine grit. I've had this stone over 10 years now. Magic! This is followed by a Medium Spyderco, which raises a very fine microbevel in about 8 strokes. On a PM-Vll blade it is so small that one must look carefully to see it. Five strokes on a Ultra Fine Spyderco, and I could call it done. A few strokes on either Veritas green compound on planed hardwood or the 0.5 micron diamond mesh, and the blade is very, very sharp.

No water. No mess. I can focus on the important part of woodworking - working the wood.

The irony is that the CBN wheel creates a perfect hollow and the Spydercos remove so little steel that the hollow looks like it will last a long time ... and grinding will be done so infrequently!

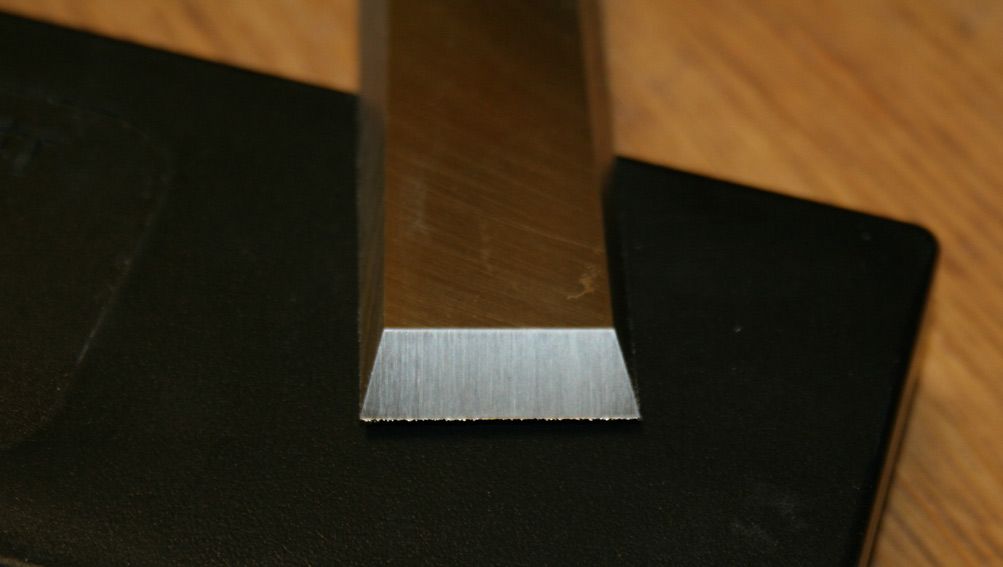

Here are images of the edges created on a 1" PM-Vll chisel blade. Firstly off the 180 grit CBN wheel ...

You can see the wire here. It is not typically ragged like that off the Tormek. It may be that the CBN wheel is new and still wearing in. It may also be (more likely) that I ground a little further than I would usually as the wheel on the dry grinder is set up fractionally off the line of the Tormek, and it was necessary to grind fractionally further to square the edge, plus the PM-Vll steel hold the wire a little more tenaciously.

Secondly, the Medium Spyderco ...

Then the Ultra Fine Spyderco ...

Finally, a few strokes on a 0.5 diamond mesh to add a final polish and ensure the wire edge is gone. And demonstrating that edge on soft Radiata Pine ...

The stones: Medium, Ultra Fine Spydercos, Diamond mesh (on perspex on hardwood), and Fine Eze-lap.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

26th October 2014, 09:03 PM #29

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

FWIW, my wheel comes from site sponsor Carroll's.

It's 40mm wide and the cost including the arbor adapter was about the same as the closest D-way equivalent (1.5" or 38 mm) with square shoulders and arbour adapter, but I expect freight from the US would be a tad more?

The square shouldered wheel will more useful to me because mostly I will be using it for shaping/sharpening metal work tooling.

A radiused edged wheel on the other side of the grinder would be nice though

-

26th October 2014, 10:57 PM #30

Hi Bob

The 40mm was not on on Carroll's site when I was researching the wheels. Only the 25mm was available. The US price was the same (in USD) but shipping was an extra $50. I would imagine that the quality is the same.

What is your experience so far?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

bench grinders

By Bendle in forum SHARPENINGReplies: 4Last Post: 27th November 2013, 07:11 AM -

Bench Grinders

By Harryt8 in forum SHARPENINGReplies: 31Last Post: 2nd May 2013, 02:53 PM -

bench grinders

By Farm boy in forum HAND TOOLS - POWEREDReplies: 2Last Post: 11th January 2005, 03:19 PM -

Bench Grinders

By antman in forum WOODTURNING - GENERALReplies: 18Last Post: 23rd August 2003, 02:04 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote