Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 1 of 1

Thread: Corner Clamping Tapered Parts?

-

21st November 2020, 10:10 PM #1

Most Valued Member

Most Valued Member

- Join Date

- Aug 2015

- Posts

- 4,423

Corner Clamping Tapered Parts?

Corner Clamping Tapered Parts?

Hi there!

I hope this is the correct area to ask, but I'm about to do a bunch of brazing on 0.125 aluminum foot shell parts (about two dozen) for a full size Star Wars R2D2 build.

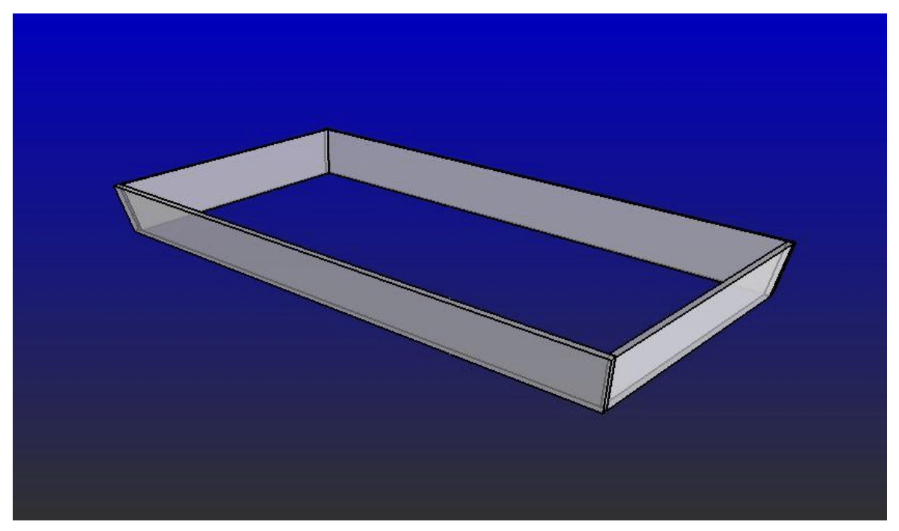

Problem I'm having is that R2D2's feet / these parts are pyramid shaped and requires a weird corner clamp angle I'm not sure how to achieve.

For instances, the very first parts you put together are corner welds, but tapered out:

Normally I would just square my parts up by eye and let it rip, but because there are so many parts here that need replica precision, I want to get things truly squared up and not just by eye.

How do you normally clamp a 90deg corner that tapers?

Thank you in advanced!

Read the full thread at metalworkforums.com...

-

21st November 2020 10:10 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Posts

- Many

Similar Threads

-

Tapered pipe threads - are the sockets usually tapered too?

By MWF FEED in forum METALWORK FORUMReplies: 0Last Post: 31st August 2020, 02:00 PM -

Pallet table bowing corner to corner

By philcal in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 3Last Post: 10th April 2019, 11:51 PM -

Help with corner to corner join

By Tegmark in forum WELDINGReplies: 10Last Post: 25th June 2015, 06:27 PM -

Clamping Help Needed! Irregular shape clamping

By retrowoodwork in forum GLUEReplies: 8Last Post: 6th April 2015, 06:43 PM -

Clamping tapered boxes

By mfseeker in forum WOODWORK - GENERALReplies: 3Last Post: 17th January 2007, 12:52 PM