Results 1 to 15 of 34

-

5th February 2013, 02:47 PM #1

The Charles & Hunting "Alta" Combination Machine.

The Charles & Hunting "Alta" Combination Machine.

I thought everyone would like to see a trio of little combination Machines I have been working on for a couple of friends, two of the machines have been sandblasted and powder coated in Blue, the other which belongs to my Father is just getting the bearings done, Dad likes the original look of it as is.

I have known about these little combination machines since I was an apprentice Carpenter & Joiner in the 1980s the company I worked for had one set up just for doing groves in the bottom of bank draws in their joinery shop, as a Young Apprentice I lusted after one of these for many years, and they dont turn up for sale often.

Its only been since earlier this last year that they have been popping out of the woodworks, pardon the pun, I have seen three for sale this last year alone.

The Alta as they were called were made by Charles & Hunting, I believe they began Works at Sydenham Street Highett, Melbourne Victoria, in the Late 1940's, Their famous single pin Dovetailing machines started to appear in McPhersons (Tool and Machinery Dealers in Australia) catalogue's as early as 1955.

C&H Made a wide variety of machines including Shapers, horizontal Borers twin and single, Dovetail machines, Table saws, Combination Machines, sanding machines, etc.

C&H Made (in my opinion) one of the best small combination machines in Australia, these little Alta combination machines appeared in the 1960s anniversary McPhersons Catalogs. (1860 to 1960).

The whole unit had two Rubber wheels under the base so It was very mobile around the work shop.

If you were a Carpenter in the 50s and 60s doing a lot of estate work say fit out and finish it was not unusual to see a machine like this out on site set up in the house being worked on, they were perfect for ripping timber or planing the edge of a door. As a Carpenter these were a luxury, one of the extra attachments was a grinder that bolted on the table, perfect for sharpening chisels on the Job. (see Pic below)

Sporting a 25 X 21 cast iron saw table and a 12 inch blade size, fine adjustment fence and a 17 X 11 Dowelling Table below one side and a choice of two sizes of 6 inch Jointer with a 3 blade cutter-head, Model A 34 long table and Model B 48 in length.

From what I know C&Hs woodworking Machinery line ran its course some time around 1965 selling their machinery designs to South Australian firm Wood-Fast and the firm going on to concentrate on its line of variable speed motors some of which they supplied to L.S.Barker woodworking machinery in North Melbourne and later Waterdale Road Heidelberg, for the feed system on their thicknessers.

I recall an abrasive flap wheel sander with a varable speed motor for sanding moldings where I did my apprenticeship that was also made by C&H around the early 1980s.

Melbourne Matty.

Melbourne Matty

-

5th February 2013 02:47 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

5th February 2013, 07:16 PM #2

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Hi Matty,

Now thats the way to do it

(3 thumbs up for 3 restorations). How easy would that be...."Now were did that bolt go....I knew I should have taken a photo....oh well, I will just have a look at the other one, and the other other one

(3 thumbs up for 3 restorations). How easy would that be...."Now were did that bolt go....I knew I should have taken a photo....oh well, I will just have a look at the other one, and the other other one .

.

Like the look of the powder coating, I think I am going to have to give that a go soon.

Cheers,

Camo

-

6th February 2013, 01:41 PM #3

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2010

- Location

- Port Sorell, Tasmania

- Posts

- 592

Powder coating

Powder coating

G'day Matty

How's the powder coating going now you've done a couple of machines? I have had a powder coater refuse to do cast because porosity in the cast will cause pin holes in the final coat due to expansion of gas in the pores with heating. Have you noticed this as a problem? I had the frame of a motorbike powder coated a few years ago and was quite happy with the result, both quality of the job and cost. Am unsure about my old cast machines, keen to hear feedback. Have been slowly doing up an old Peerless bandsaw and there is a fair bit of porosity in its castings. Don't think it would have come up well with powdercoat. Is the quality of cast iron more of a problem with older machines, or just the cheap old ones.

Tony

-

7th February 2013, 08:50 AM #4

Hi Tony,

I have never had a problem powder coating cast iron, if the cast is to be kept outside my powder coater uses an etch primer before powder coating just to help with longevity.

The Quality of the cast does play a big part, but any cast can be powder coated, sand blasting also helps to key the material on the surface.

These little Alta's have come up well as only the tops are cast iron all the rest is fabricated steel bar and sheet panels.

More recently I did have good results with the L.S.Barker planer that I powder coated , which had some imporfections in the cast that needed filling, this was possible using a marine grade filler, and the powder coating just went over with a good finish !

I have seen my powder coater give peices an extra thick coat of powder before they go into the bake oven, but I have never noticed pin holes on his finished work before, and I have had a lot of material powder coated over the years.

Melbourne Matty.

-

8th February 2013, 03:39 PM #5

But wait ! There's more.....

But wait ! There's more.....

All the Alta machines I have come across have had the fine adjustment broken and welded/brazed back together, it took me a while to work out why but until you have owned one and moved it around you don't realize how heavy they are.

There are two small rubber wheels built in under the machine and when they are in a stationery position are very stable unit, it's not until you lift at one end and go to push that it is then they become unstable and can topple over, for some reason they always land on the fine adjuster side of the saw, many a swear word has been said when this happens.

The Alta's have a beautiful little horizontal boring table to one side of the machine, there is a height adjustment via the saw blade rise and fall, the chuck is just a half inch hole with a grub screw, and the table folds down out of the way by removing a tapered pin arrangement.

The motor arrangement is very interesting, the Alta utilizes a duel shaft motor to run both the buzzer and saw at the same time, earlier Alta combinations had a single belt arrangement to the 12 inch saw but later models had a twin belt set up and always a single belt to the 6 inch planer, Motors ranged from 240 volt and 415 volt, 1 HP to 2 HP.

It is possible to retro fit a larger modern 3 HP single Phase motor to these machines, as we purchased one with no Motor, so had one custom made last year and it fitted up great.

Dads Alta is the only machine I have seen with the original switch still intact, most others were replaced.

One of the mitre guides offered with the alta, a nice big guide but make sure the locating pin is in the table grove as a stop otherwise you will cut straight through it.

Melbourne Matty.

-

8th February 2013, 05:59 PM #6

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

I like the mitre guide, and I didn't notice before the mitre slot extension, out of curiosity do you find this extension to be a benefit when normal use of the table saw, or does it sometimes get in the way, I could see it being a painful protrusion depending on how tall the operator is?

depending on how tall the operator is?

-

8th February 2013, 09:07 PM #7

Haaha, depends if your running at it or not, narr its all good Camo, I haven't had a problem with it and it is handy for the wider crosscutting of timber.

its probably another thing that is prone to getting damaged as well as the fine adjustment if it topples over .

Melbourne Matty

-

13th February 2013, 10:12 PM #8

Matty,

I can see my Woodfast ripsaw in those machines

... the fine adjustment, non-tilt, and the boring table and the fence lock ...

Cheers.

Paul

-

15th February 2013, 12:13 PM #9

-

16th February 2013, 07:32 PM #10

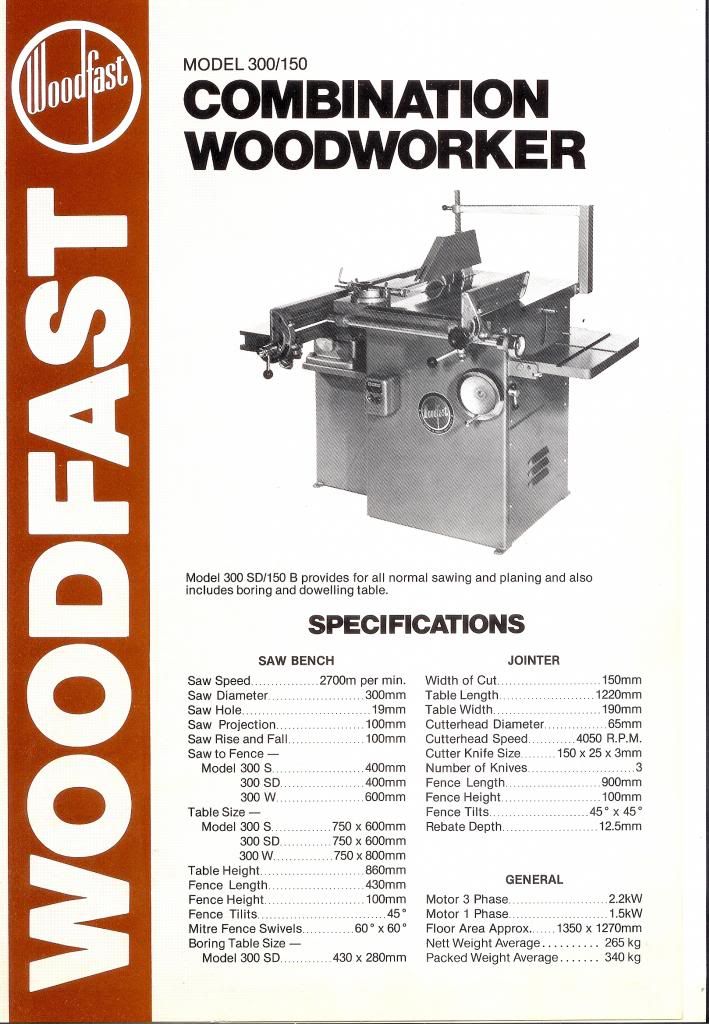

The Woodfast "Alta"

The Woodfast "Alta"

Paul, this machine is one of the reasons I am pretty sure Woodfast took over Charles & Hunting at some stage.....

Melbourne Matty.

-

17th February 2013, 11:53 AM #11

C & H variable speed motors.

C & H variable speed motors.

A modern solution to an old problem.

The C & H variable speed unit.

Charles and Hunting.

Sydenham St, Highett, Victoria

A two page sheet with price list and ratios from 1952 saved from Civ Eng Usyd.

I have 2 of these units one on a wood lathe and the other destined for a big single disc sander.

C & H also made a nice morticer have a photo somewhere in the pile and when I get the computer to talk to the net again and the scanner ditto to the computer I will post it and the early Wadkin stuff I mentioned in an earlier post.

H.

-

17th February 2013, 04:14 PM #12

I would like to see that H, I have see a spindle moulder and boring machine made by C&H but not a Mortiser.

In the 80's and 90's Woodfast morphed the Alta into their very own Combination machine, there were still many of the features that were on the original Charles & Hunting Alta.

The 6 inch planer is a dead ringer as is the fences, fine adjustment, doweling table etc..

Melbourne Matty.

-

18th February 2013, 11:33 AM #13

Woodfast combo

Woodfast combo

We had one of these machines in the Industrial Arts teacher training workshop at NSW Uni in the mid seventies.

I replaced it with a Wadkin BGP from Austral engineering and from memory Barry Gabbit was the salesman.

The woodfast was at least 10 years old then so I wonder what the date was they took over Alta?

It is my understanding that Woodfast also took over Hyco.

The wood lathe, scroll saw,band saw are all direct descendants.

I have always wondered why Woodfast didn't continue with the Hyco tilting arbor cabinet saw.

The first Hyco version was a little basic with a lever for the tilt but later ones had hand wheel adjustment same as the Wolfenden and Australian made AGS Wadkin.

Small cabinet/dimension saws were once very hard to find and the early Tiawanese junk didn't help the situation based as they were on Yank designs with no provision for fitting riving knives.

H.

-

18th February 2013, 09:38 PM #14

-

18th February 2013, 11:30 PM #15

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Similar Threads

-

eBay: How long can you "Save" the "Draft"-listing of an item you want to sell?...

By Batpig in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 0Last Post: 22nd January 2011, 06:04 PM -

Wanted to show off my "Shable" shelf/table combination.

By The0ldMan in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 14Last Post: 23rd June 2010, 07:31 AM -

Charles and Hunting Tablesaw

By CC&C in forum HAND TOOLS - POWEREDReplies: 0Last Post: 6th September 2004, 03:25 PM -

Dyco "woodworker" 5 in 1 machine

By Dion N in forum HAND TOOLS - POWEREDReplies: 9Last Post: 20th August 2004, 02:51 PM

Thanks:

Thanks:  Likes:

Likes:  Needs Pictures:

Needs Pictures:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote