Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 11 of 11

Thread: old foursider

-

23rd September 2013, 09:28 PM #1

Senior Member

Senior Member

- Join Date

- Feb 2013

- Location

- Glen Innes

- Posts

- 127

old foursider

old foursider

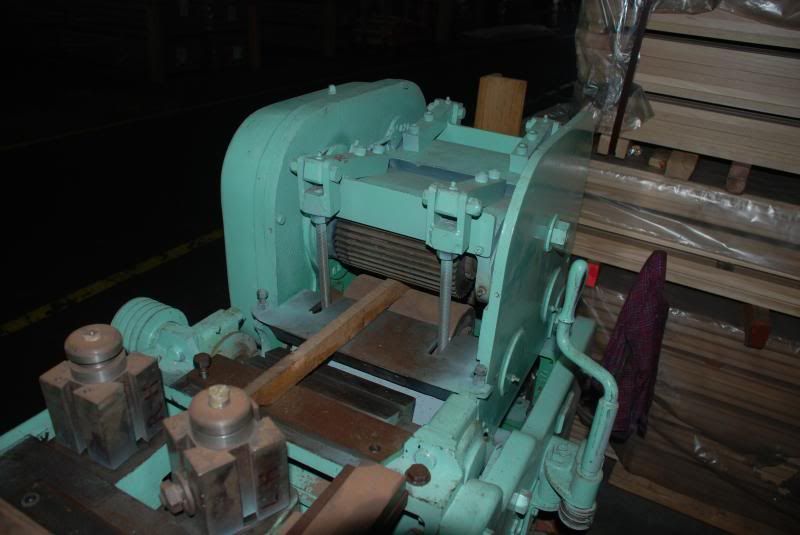

I finally talked my boss into buying a four header (always handy round a sawmill)and this is what he came up with

One of the motors is missing and its a square header but it is in otherwise pretty good shape. So, my question to the experts is this, is it possible to put round heads (maybe off a spindle moulder)on the machinecheers pat

-

23rd September 2013 09:28 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

23rd September 2013, 11:08 PM #2

In my humble opinion, I can't see why you couldn't fit round cutter bars instead of square. You may find though, that the cost may not be viable given the age of the machine and a possibility that the round cutter bars will have to be "custom made". The sellers of the spiral cutter heads say that they can fit them to "most" planers.....but I would say they would be expensive.

Good luck with it all.Just do it!

Kind regards Rod

-

24th September 2013, 12:02 AM #3

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Hey 1thumb,

Sorry I can't offer too much in the way of assistance, but I know Melbourne Matty (L.S.Barker1970) has a Premo four sider, so hopefully he will come by soon, he runs it with square heads, but may have some advice on suppliers, options, etc.

Cheers,

Camo

-

24th September 2013, 08:19 PM #4

Senior Member

Senior Member

- Join Date

- Feb 2013

- Location

- Glen Innes

- Posts

- 127

Hey fellas thanks for the thoughts I only ask about changing to round heads as I tend to think that tooling for the squares would be as rare as hens teeth. I am actually looking forward to getting this old beast up and running which I am sure will be inexpensive

, but fun

cheers pat

, but fun

cheers pat

-

25th September 2013, 07:23 PM #5

Hi Pat, I am familiar with the Neale four sider as a good friend has done a rebuild on one.

They are a beautiful solid little machine and nice and easy to set up.

As for changing the heads, the answer is yes to changing the side heads, that is easy, there is simply a bolt on the top and away you go.

Also depending on the shaft diameter most tooling will just drop on or require a spacer or bush to suit One inch and a quarter bore size tooling.

The two horizontal heads are a very different and a more difficult proposition, both have plumber-blocks and bearings either side of the main head so sliding anything on and off is impossible.

It may be possible to have the top and bottom "custom" heads made up, either in a serrated back knife head (that would allow square dressing of timber and some custom profiles of moldings to be run)

or if your work is just square dressing why not as suggested a spiral helix or byrd head.

All of the above options may be very expensive as chambezio has mentioned, and would have to be researched and options weighed up.

To be honest, in my opinion the square head is the best, thats what I run on my four sider with fantastic results.

Tooling is not hard to find, I have a great saw-doctor here in Melbourne who makes most of the larger profiles for me, and on the odd occasion I will hand grind a very small pair of cutters myself, but it takes time and patience.

If you stay with the square head, make sure your tie down bolts, nuts and washers are in pristine condition, cutters balanced and set correctly, square head cutters can be very dangerous if you are not confident or clear about what you are doing !

Pat I am happy to elaborate on any of these points or give more advice if it helps..

Melbourne Matty.

-

26th September 2013, 08:19 PM #6

Senior Member

Senior Member

- Join Date

- Feb 2013

- Location

- Glen Innes

- Posts

- 127

Hey matty thanks for the offer of help, I may just take you up on that at some stage. At the moment we were planning on using just the side heads and because Its not a fun "home"

project round heads might be the easier option

P.s thats a corker of a planer in those pictures here's one from my boneyardcheers pat

-

1st October 2013, 12:31 AM #7

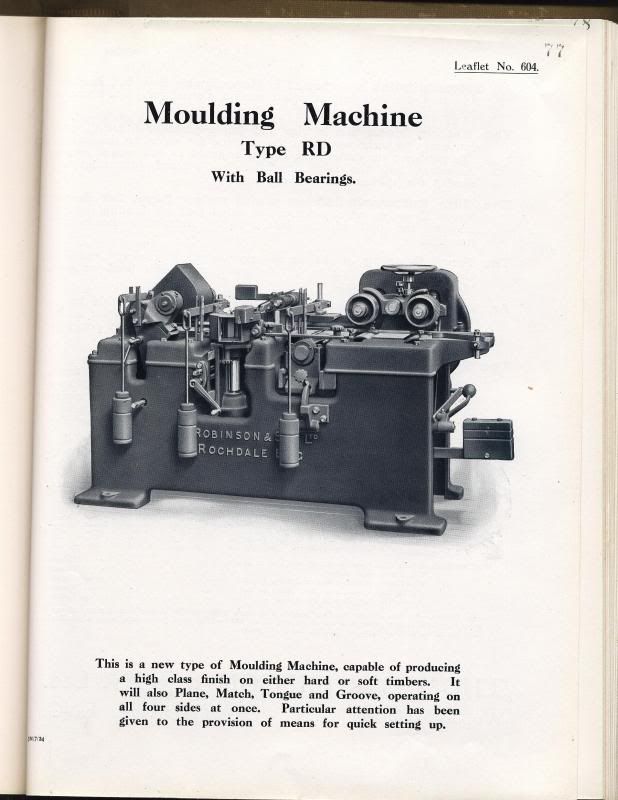

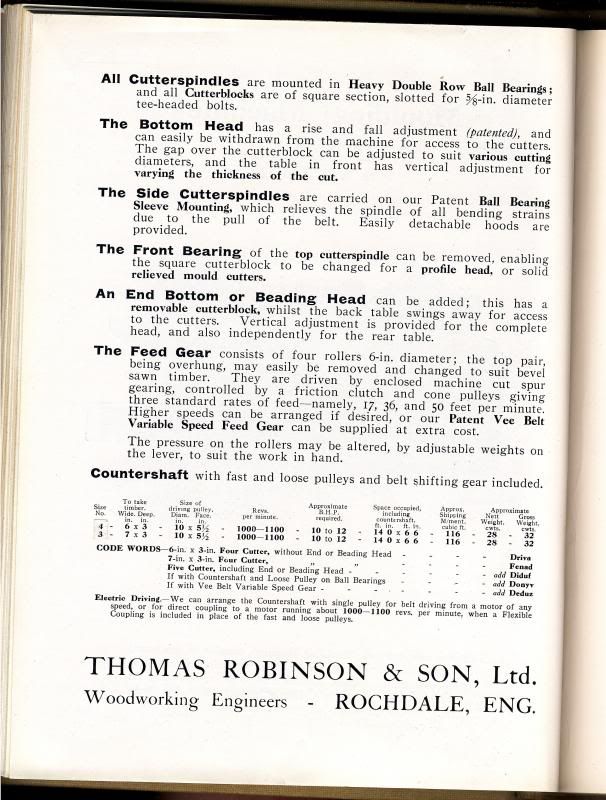

Pat, that Robinson is a lovely old machine, I'm a little sad to see it in such a state, but at least the scrap man hopefully doesn't get a look in.

Rusty isn't dead, and that could be a good restorer !!

Here are some picks also of my four sider, its a 1940's 12 inch X 4 inch Premo moulder, its a beauty, fun to use and make chips too.

Melbourne Matty.

-

2nd October 2013, 08:39 PM #8

Senior Member

Senior Member

- Join Date

- Feb 2013

- Location

- Glen Innes

- Posts

- 127

Matty,

that planer is going inside shortly , I have a bad habit of buying stuff and THEN thinking ? I refer to it as my collector/hoarder gene. as for a scrappy getting any of my stuff--when hell freezes over!! your premo is quite the nice machine and it looks like it sees some use too

? I refer to it as my collector/hoarder gene. as for a scrappy getting any of my stuff--when hell freezes over!! your premo is quite the nice machine and it looks like it sees some use too cheers pat

cheers pat

-

2nd October 2013, 11:51 PM #9

-

4th October 2013, 09:57 AM #10

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Matty,

Great to see a machine like the Premo with a good pile of chips around it

. Glad to see your new scanner is getting a workout too, thanks for the detail on the Robinson RD, she has some weight (28cwts that's over 1400kg

. Glad to see your new scanner is getting a workout too, thanks for the detail on the Robinson RD, she has some weight (28cwts that's over 1400kg ).

).

Cheers,

Camo

-

4th October 2013, 08:15 PM #11

Senior Member

Senior Member

- Join Date

- Feb 2013

- Location

- Glen Innes

- Posts

- 127

Likes:

Likes:

Reply With Quote

Reply With Quote