Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Results 1 to 15 of 21

Thread: Sterling Supersaw

-

12th December 2011, 11:41 AM #1

Sterling Supersaw

Sterling Supersaw

I just realised I hadn't introduced 'brutus'.

Cast in the side it says Supersaw manufactured by Stirling Machinery, North Ryde NSW.

It/he was put on the side of the road in our industrial area. The guy had downsized from a factory making rubber-treaded jarrah floor 'tiles' that he was exporting worldwide ... then had a break ... maybe marriage or health issues ... and was starting back with a smaller pallet repair business and didn't want it any more.

5hp motor, and came with the 11" dado set ... 62mm wide and happy to rip straight across/through a jarrah railway sleeper. It was my first machine it occurs to me now ... obviously the cause of all the trouble

Cheers,

Paul McGee

-

12th December 2011 11:41 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

12th December 2011, 02:20 PM #2

I have a very similar machine but mine does not have the support at the front. Is that original or a home made add on?

Mine has a single phase motor but you would need every bit of that 5HP to drive that monster dado

-

12th December 2011, 02:45 PM #3

The previous owners had made the table it sits on, the support at the front, the arc'ed cutout for the support to travel left and right with the arm.

I only added the plywood base sheet ...

I had to go outside to remind myself ... it came with only the levelled metal frame, and two long metal cross supports 40mm x 70mm cross-section, with "dog-holes" ... female threaded holes in pairs every 50mm. They would set it up for a particular cut or cuts and just run them off over and over I guess.

You'll see in photo there was also a bracket to make the finer adjustment between the 50mm spacings.

The support was to take out any tendency to for the arm to drop as the motor/etc is slid to the front ... but ... when you are working the handle at the rear to raise/lower the arm ... and you forgot to loosen the front support ... "Dammit, why is this so difficult to ... doh!"

Cheers,

Paul McGee

Scroungers Anonymous will meet every second Tuesday of the month ... unless there's a road-side collection on.

-

12th December 2011, 02:58 PM #4

Ever thought about going into the "rubber-treaded jarrah floor 'tiles' " business, pmcgee? For those who don't already know, that 3 blade setup is for one pass trenching. The 2 outer blades cut the sides of the trench and the dado blade removes the middle section, all in one swipe. Could do a fair bit of work I'd say.

-

12th December 2011, 03:13 PM #5

I have a very old (50's) MBT Cut 12" that I have had since i was a boy. You need to have your "Weeties" if you to move it because its cast iron. the shaft the cutting head runs on is hexagonal and had a depression worn in it where it sits at rest so every time you pulled it out it would do a little "wiggle" and make a not so flat cut on the end of what you were cutting. To rectify this I rotated the Hex one turn and it runs on a fresh "flat" of the shaft. I picked up a 2" wide fixed trenching head for it. It is great for timber frames for houses and the odd fire wood break down but it usually sits ready to be used in the shed now. My brother-in-law gave me his fathers old "SAWMASTER" as he had never set it up after his father died. I put new bearings in the main spindle and motor (maintenance was not high on his father's priority list) and she runs very sweet. It came with an adjustable trenching head which can go between rough sawn or dressed framing timbers.

They are the type of saw that I don't use a great deal but when you have a job on that they can be used on well...that's when they come into there own.Just do it!

Kind regards Rod

-

13th December 2011, 12:09 AM #6

Paul

very interesting docker.

theses non yoke saws that pivot on the arm are not that common, and your with the motor up top gives a better depth of cut. Stenner made a saw that pivits on the arm. Could you show how thats works?

the stenner with built in dust shoot.

Note where miter privet is as well.

http://i927.photobucket.com/albums/a...3/stenner1.jpg

jack

English machinesAll tools can be used as hammers

-

13th December 2011, 08:01 AM #7

Ohhhhhhhhhhhhhhhhhhhhh ....

It is hours now after I first read your post and I *just now* figured out the swivelling action. I could not see what was going on with that big bolt in the front ... but I finally saw the curved back to the table.

Still kinda wierd 'though!

I see the chute for chips to 'chute' out ... and I now see that the whole saw can swivel around at the back to make an angle. I'd been looking at the sides of the table and wondering why they were there when the centre section was so much higher ... I get that part now.

BUT ... what I still don't see is ... where the flock do I lay a 2m jarrah post that I want to cut in half???? Do you have to make auxillary tables on either side? Even the head of the bolt out front ... why not flush it to the metal?

I can't really picture how you use it.

But then, I am easily confused

Cheers,

Paul McGee

-

13th December 2011, 05:24 PM #8

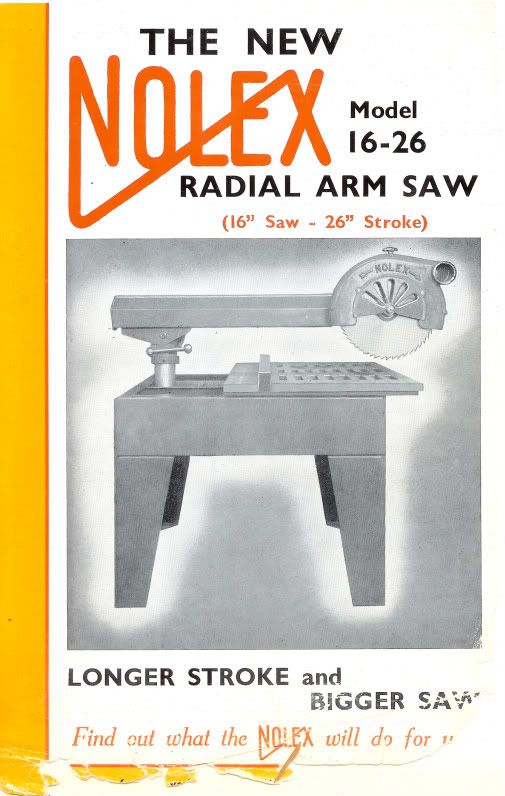

what about the Nolex ?

what about the Nolex ?

Paul, I would of thought you would of gone a Nolex Radial saw, these things were native to Western Australia, 241 Railway Parade Maylands to be exact.

Just about every timber yard I went to and every Joinery I worked had one of these Nolex Dockers down here in Victoria.

Any way I could Honestly say the supersaw is quite a good docker as well having worked on one years ago where I did my apprenticeship.

A very slick machine indeed, I don't mind the Aussie made dockers.

I have two Italian machines a Tatry and a Omga.

Melbourne Matty.

-

14th December 2011, 08:18 AM #9

Apparently this guy was sending shipping containers of them to Italy, Japan, US, Europe, etc ... before the GFC. Said he was making a killing.

The idea was something like a 12" square made from jarrah 2" boards, and they clicked together with a rubber/plastic undersection.

sounds special huh?

sounds special huh?

-

14th December 2011, 08:21 AM #10

-

14th December 2011, 11:26 AM #11

bigger

bigger

Hmmm ...

why not just go with this? On two Army trailers ... ex-Puckapunyal ...

portable sawmill ex army | eBay

-

14th December 2011, 12:01 PM #12

It never rains ...

It never rains ...

(Blame ebay)

First pic is my RAS ...

Second is the identical machine being sold in Toodjay WA (pic 2) ... compare the manufacturer (pic 3)

Radial Arm Saw Heavy Duty | eBay

Third - smaller machine - different again -

Sawmaster Radial Arm Saw | eBay

Fourth - same as the last one - but can't see the make on this one -

Australian made Sawmaster radial arm saw - Compound Slide | eBay

But ... the third guy is also selling the "adjustable trencher" that he runs on the RAS. (last 2 pics)

Is this off a spindle moulder do you think?

The spindle on the smaller saws is 3/4in (19mm) ... my model is 30mm (pretty sure).

Now I'm wondering about the possibility of using moulder tools in the RAS?

Stupider than usual??

Paul McGee

-

14th December 2011, 02:02 PM #13

Hmmm, that first one looks familiar.

Or should I say 'Snap"

Or should I say 'Snap"

From memory I think the spindle on mine is an odd size. 7/8" or 22mm

-

15th December 2011, 10:53 AM #14

Senior Member

Senior Member

- Join Date

- Sep 2011

- Location

- Northern Beaches, Sydney

- Age

- 68

- Posts

- 329

I doubt if that cutter head is off a spindle moulder.

I've used several like it to trench bottom plates ( quite a few years ago though ) and one of them was adjustable so you could wind it wider for rough sawn timber and then down smaller for dressed framing timber.

Those Sawmasters are good old saws. I know a couple of old school carpenters who have them - both since retired and they are what they used to set up on site to frame a house. Not excactly as portable as a docking saw or lighter RAS but very capable once set up.

Stewie

-

5th October 2012, 06:08 PM #15

So ... outta the blue ... the guy who I bought the Dankaert saw off called me and asked me if I wanted a Nolex RAS.

He had plans for mounting a router onto it, but cleaning up the workshop ... free to good home.

What could I say?

3 phase, cord missing ... and a 40hz motor like on my thicknesser. Old? Nooooo.

Cheers,

Paul

P10100317.jpg P10100319.jpg P10100320.jpg P10100321.jpg

I've seen quite a few pics ... I think this is the closest I've seen:

Similar Threads

-

sterling silver Baron

By cornucopia in forum WOODTURNING - PEN TURNINGReplies: 10Last Post: 16th July 2010, 04:39 PM -

Sterling Silver Sedona

By Les in Red Deer in forum WOODTURNING - PEN TURNINGReplies: 10Last Post: 2nd October 2008, 02:12 AM -

Sterling Silver Sedona

By Les in Red Deer in forum WOODTURNING - PEN TURNINGReplies: 8Last Post: 30th August 2008, 05:44 PM -

6 pens a pound sterling

By jow104 in forum WOODTURNING - PEN TURNINGReplies: 2Last Post: 19th July 2008, 11:43 AM -

Sterling Silver Sedonas

By Froggie40 in forum WOODTURNING - PEN TURNINGReplies: 12Last Post: 21st February 2008, 11:34 PM

Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote