Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 23

Thread: A wadkin PK for Me

-

15th February 2014, 02:37 PM #1

A wadkin PK for Me

A wadkin PK for Me

I had seen jgforsburg [Jack] PK posted here a while back , I never knew what one was before that day a very big drool and dream session followed, Wow what a saw ! One of those would be nice.I also saw a PK AJOE123 posted . Very nice !!

I had a bit of a hunt around on the net for other images of PK's,checked all I could for a little while on what comes up in the UK on ebay, read a lot here how people kept coming across them . looked through a few second hand dealers sites . Then I forgot about them and went off picking up other pieces of older machinery here and there , they are a rare sight down here, in Melbourne Australia.

Then about six months ago I get a phone call from a Cabinet Maker friend , He has always dropped in on me at work for a chat , one day I was going to go out and drop in and see his workshop but had never found the time in fifteen years to do it.

He says to me " Hi Rob , hows things ? " and get's to the point of the call , " have you ever heard of a Wadkin PK ? "

"Yes "I say , "Ive never touched or seen one though , apart from on the computer."

"would you be interested in buying one ?"

"Yes !! "

"well come over to my house and see my PK and we will take it from there "

"Thanks ", I said . hiding and excitement in my voice ,and hung up .

I couldn't really believe it .

I went over and got to see his PK , says" what do you think "I said "Its the most beautiful saw Ive ever seen "

The original paint, grey machine was in his uncles factory from new when he worked there,when they closed he got it.

So I get introduced to the seller of the saw, Buying this machine took about six months of delicate negotiation. I was not allowed to go see it , and he finally agreed to take pictures , I had to decide based on the pictures and he wanted $2500, I was willing just to walk away from it but I didn't.

The good part about the deal was a lot of the saw was there , it has a left extension table . it has no twin miters or quadrant fences and a filler strip is gone . The rip fence is a copy that needs some work.

The seller was bringing it from a few hours out of town to a suburb near me , where it would be fork lifted on to Mattys trailer for me to tow . We backed the trailer up at my workshop and pulled the saw of the trailer on to two 50x50mm steel square hollow section with block and tackle. With a squirt of diesel fuel on the rails, the two of us then pushed it in by hand, it was like the PK was on skates.

Thanks Matt for the help , sorry about jamming your finger in the block and tackle like I did, there was a PK on the other end of the chain and it must have hurt bad . And thanks to Jacob and Dorris for showing me His PK and helping clear a space for another machine at 6.30 in the morning. and Thanks Vince.

Rob .

-

15th February 2014 02:37 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

15th February 2014, 04:18 PM #2

Senior Member

Senior Member

- Join Date

- Feb 2013

- Location

- Glen Innes

- Posts

- 127

Can understand how you couldn't just walk away from it

Awesome bit of gear how big is the saw in it?

cheers pat

how big is the saw in it?

cheers pat

-

15th February 2014, 04:28 PM #3

The saw angles have smiled open the. Read about it on Canadian this morning and thought you lucky bugger.

Frank.

In trying to learn a little about everything,

you become masters of nothing.

-

15th February 2014, 10:17 PM #4

Thanks Frank and Pat

The blade in it at the moment is 15" but it takes an 18'' blade. its 4 HP and cuts 4.25" deep with the 18" blade in it.

I pushed a piece of wood through it for the first time on Thursday , I ripped a bit of 4x4 pine in half with two passes . Oh boy I wouldn't want to get caught out doing something silly with a saw that size. the riving knife made me glad it was fitted. I stood well out of the way and took it slowly .

I Just need to use it and get used to it once it is all running right . And never stop paying it my respect by stopping each time I enter or leave the machine room , face all the machines , bringing my feet together and my hands by my side and lean forward and bow my head in deep respect.

Rob

Rob

-

15th February 2014, 10:48 PM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Rob,

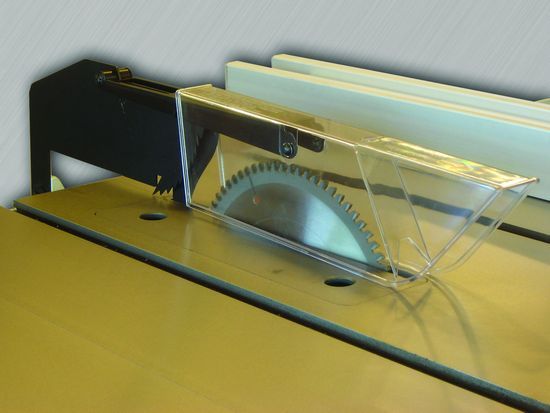

You have done well!! Glad you have had a chance to put some timber through and get a feel for the power of these saws. Wait till you get an 18" blade in it. I use the Stenner with a great deal of respect, the prospect of a kickback from an 18" blade being moved by 5HP direct drive . This is why one of the things I like about these patternmaker sliders, are the safety features you might not expect from an older saw,and don't see in most new cabinet saws, a true riving knife (as apposed to a splitter), overhead guard, so no need to remove the guard when not making through cuts, short fence to prevent binding after the cut.

. This is why one of the things I like about these patternmaker sliders, are the safety features you might not expect from an older saw,and don't see in most new cabinet saws, a true riving knife (as apposed to a splitter), overhead guard, so no need to remove the guard when not making through cuts, short fence to prevent binding after the cut.

The Wadkin Bursgreen AGS is a nice saw, but you are going to love the PK.

Cheers,

Camo

-

16th February 2014, 12:00 AM #6

Thanks Camo,

In those catalogs you and Matty have , have you noticed any Wadkin 3/4 inch thick cast iron under pants, suitable for learners on big saws??

Whats the exact difference between " a true riving knife (as apposed to a splitter)" ?

Matty was telling me the other day a riving knife should be thicker than the saw body in thickness and thinner than the kerf that the blade cuts.

Ive never put much thought into them, and never used them much on my smaller saws. The Carbatec saw I used [pre my Bursgreen 10 AGS] came with one that was part of an over the blade guard. it was made from mild steel and keeping it true drove me to the point of tossing it out the door.

I wont be doing the same on this saw.

Rob

-

16th February 2014, 12:52 PM #7

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Rob,

Prior to the Stenner, I have only ever owned a maximum 12Ē blade 3HP machines, so I understand your healthy respect for these machines. I think however, once you look past the intimidation factor of an 18Ē vs a 10Ē blade, you are now in a much safer position with the PK, than you were with the Bursgreen 10AGS, due to the build quality and safety features of the PK.

Donít get me wrong, I still get a bit of a raised heart rate when the 18Ē blade starts spinning, but I think a bit of healthy respect is a good thing, it sharpens the mind, and makes you think about what you are doing. As long as it doesnít turn into fear and start impairing good judgement or action, your fine, and having seen your workshop, and your work, it is clear this is not going to be a problem for you.

I am no expert, so if anyone wishes to clarify or correct some points, feel free to do so.

I guess the first thing is to look at why we have a riving knife/splitter fitted. It is to prevent kickback. A kickback occurs when the timber that has been cut comes into contact with the back part of the blade. As at this point the blade is traveling up and towards you, the workpiece is thrown back at you, and as you are pushing the workpiece forward at the time, you may have a tendancy to move towards the blade. Now I am not stupid enough to demonstrate a kickback, so here are a few others I have found .

.

http://www.youtube.com/watch?v=xFkHmgRIkOI

Well actually Matthias is far from stupid, he is a genius, but I guess that is why you can see him cautiously trying to create a kickback. My thoughts on this demonstration, is the kickback lacked power, as the fence is the second crucial element to a really bad kickback, but as he says the concern is where your hands will end up in this example.

Here is a real kickback, and this guy admits he was an idiot:

http://www.youtube.com/watch?v=u7sRrC2Jpp4

As you can see, it is fast, and once set in motion completely unstoppable, and I think it would probably make little difference if you have a 10Ē or an 18Ē blade set to the correct height for cutting.

Anyone who sees this video and continues to remove or use a saw without a splitter or riving knife IMO is an idiot!! If I had a splitter that was a piece of garbage, I would either get rid of the saw or stop cutting until I had put some serious effort into making or buying a better riving knife or splitter.

Firstly I should say that if correctly fitted and made of quality materials, they should both successfully prevent a kickback. The riving knife is just a much better design since it is attached to the same part of the saw as the blade. That means it keeps a constant distance from the blade regardless of how low the blade is set. You also don't have to take it off for non-through cuts since it is coming from below with the blade, not attached to the back of the table. An overhead guard also means you can guard the blade when you are doing a non-through cut.

This is the kind of splitter guard arrangement, on most modern cabinet saws that I have seen:

What you describe here is exactly the reason I started looking for an older saw, and probably the reason most take the guards off. I have been criticised more than once for saying negative things about new Taiwanese and Chinese made saws, but I hate the fact that they seem to have decided to make cost savings on the most important safety feature of the saw.

I couldnít afford a new industrial saw that had well-made effective safety features, and I didnít feel confident with what was available on a modern entry level cabinet saw, my concerns with an old saw was that safety features may not be present, but at least on these patternmaker saws, this is certainly not the case.

Most talk about the fact that the riving knife is better because it enables you to perform a non-through cut, either for dado work or like you did earlier this week, ripping a 4x4 in 2 passes. This is definitely true, itís impossible to use the splitter and guard pictured above to cut a 4x4 in more than one pass, so now you are tempted to take the splitter off, and with it the blade guard to do the cut, this is when accidents happen, and in this example with a heavier piece of timber (the correct thing to do would be to make a custom splitter that is secured from below and sits just below the top of the blade, and fit an overhead guard for this cut, but I bet a lot of people just make the cut with no splitter or guard, hoping for the best, or unaware of the safety risk they are taking). The other factor for me with the riving knife, is the fact that you can set it close to the blade, and it stays that close regardless of what height the blade is set at (look at the picture above, now image the blade lowered to rip a 19mm board, that splitter starts to get further from the back of the blade than I feel comfortable with).

I agree with Matty, he knows his stuff and definitely more than me. Rob this is probably a good read, and has a section that covers proper riving knife setup (Jack put this up the other day):

http://www.hse.gov.uk/pubns/wis16.pdf

My understanding of the reason for this thickness, is if the timber comes back into the blade, you want to keep it off the body of the blade, as this is what will do most of the grabbing of the timber and throw it back at you (the actual teeth will just simply cut it). Make it as thick as the kerf that the blade cuts and you run the risk of the timber binding between the fence and the riving knife (thatís if your fence is not a short fence), especially if the timber decides to bend as tension is released with the cut (as you would know, depending on the grain of the timber, when it is cut it may want to bend).

This brings me to short fences and what I like about them. A properly set up short fence, will support the workpiece up until the last tooth makes its cut. After this point there is absolutely no benefit IMO in supporting the workpiece and only disadvantages.

Given the timber may want to bend after the cut (when tension is released), it may either want to bend towards the blade or away from the blade. If the timber wants to bend towards the blade there is no difference between the short and long fence, the riving knife or splitter keeps the timber off the blade, the riving knife just does it earlier. With a piece of timber wanting to bend away from the blade, the short fence lets it do this without resistance, whereas a long fence will prevent it. You then have an unnecessary and unwanted battle between the riving knife or splitter and the fence, and the timber that now wants to bend to the point that is now natural for it. The longer the fence and cut the more pressure, and this can result in resistance against you pushing the timber through the cut.

Rob, I went far more into detail than I know you needed, I know you are a very experienced woodworker (certainly more than me), but I wanted to make sure that anyone reading didnít misunderstand my opinions due to a lack of detail.

Cheers,

Camo

-

16th February 2014, 03:09 PM #8

Thanks Camo for a good post, I have shown the second video to the young guys at work a few times , it's a good one to see. The guy doing it almost lost body parts filming it

Those push pad plastic things he tried it with are ridiculous.

Those push pad plastic things he tried it with are ridiculous.

I have , quite a few times demonstrated kickbacks to my apprentices , standing behind the saw and dropping a board down on to a spinning blade in full flight set about 75 mm out of the table.

They sure do then understand how bad it can get if they don't pay attention , and set the guard and wear the right safety gear like we teach them. I feel safe in knowing that they fully understand the dangers.

Young guys !! the amount of times I have explained and then asked

Q. " You know what I mean ? "

A. "Yes"

Q. "Do you" ?

A . "Yes Yes"

So I spy on them and make sure , about 50% of the time they did not in the slightest!!! understand the lesson or the dangers .

so I walk in and start again ! or keep them off machines for weeks or months.

The flying piece of wood smashing into the wall , which would kill you if it hit in the head , is a good teaching tool

I warn them , "stand behind me this is what a saw can do if it goes wrong"

They look funny going from a, yawn and a stretch , "whats the boss doing, When is it lunch time ??".

Instantly to a , half crouched fight or fight position, swearing .

Then there is the Old guy problem !! You employ a woodworker in his 50's and walk past noticing he is not sticking to the " keeping your body parts rules" he has already lost two parts of his fingers at work sites , and when told ,"your going to have an accident doing that " he goes on and never changes , I walk past and see the same dumb things being done. frustrating ! For me to be covered I have to stop work, document , re teach and document , ducument with a few other meetings. The better option was to say sorry , no work here .

That guard pictured is the type I had on one of my previous saws. it got tossed and I built the over head one I now use . Worksafe came in and gave it a tick.

It does not have a riving knife but acts in a way like a riving knife in that it stops wood getting on top of the blade. And stops hands getting near a blade. The good thing is it's fitted 100 % of the time , it just needs adjusting down a few mm off the board for the danger cuts.

Rob

-

16th February 2014, 08:45 PM #9

Senior Member

Senior Member

- Join Date

- Feb 2013

- Location

- Glen Innes

- Posts

- 127

Yep, I've given the old don't let anything hit the back of the saw or this happens speech a few times myself

It usualy wakes them up but sometimes they gotta have that "near miss"to really get it to sink incheers pat

-

17th February 2014, 09:40 AM #10

Senior Member

Senior Member

- Join Date

- Nov 2012

- Location

- Sydney

- Posts

- 266

Nice saw !!

Nice saw !!

Very nice saw Rob. If you decide you just can't fit it in the workshop.....

Regards

John

-

18th February 2014, 10:44 AM #11

Never a more deserving owner. Congratulations!

... asking $2500 ... and not seeing the machine ... were you buying from Batman???

... six months negotiating ... the Iranian embassy maybe? President Ahmadinejad??

Paul

-

18th February 2014, 06:25 PM #12

lol ... I saw a friends original with an extension and fell in love with it . The first one I had ever seen in the flesh , every thing about them is top notch . the handles on the wheels are horn, I was told when I first saw it , Buffalo horn I was told later . that blew me away . The feel of the fence , mine turned out to be an average copy which needs work . that's the only part of the buy that I don't like. But I would still take it given what I now know at the start. It having the extension makes up for it . I love those big wheels as well . I have a fair bit of big timber to push though this machine. I think using it with the big blade in it and 4 HP will be exiting each time I turn the saw on. I have to pour a slab where the saw is at the moment, before I fix it up . And I have to get some woodwork done before I do that.

lol ... I saw a friends original with an extension and fell in love with it . The first one I had ever seen in the flesh , every thing about them is top notch . the handles on the wheels are horn, I was told when I first saw it , Buffalo horn I was told later . that blew me away . The feel of the fence , mine turned out to be an average copy which needs work . that's the only part of the buy that I don't like. But I would still take it given what I now know at the start. It having the extension makes up for it . I love those big wheels as well . I have a fair bit of big timber to push though this machine. I think using it with the big blade in it and 4 HP will be exiting each time I turn the saw on. I have to pour a slab where the saw is at the moment, before I fix it up . And I have to get some woodwork done before I do that.

Rob

-

20th February 2014, 06:26 AM #13

Senior Member

Senior Member

- Join Date

- Sep 2012

- Location

- Coffs Harbour

- Posts

- 226

Nice score!! I wonder how many more are hiding in someone's shed doing nothing? At least one more I hope.

So, you gunna give it the Jack treatment

-

20th February 2014, 08:58 AM #14

nice big solid saw

I'm only slightly envious, having realised it would not fit in my shed.

Camoz

I'd seen that utube before but still scares the &^%* out of me

can you show some pictures of your overhead quard? I've been trying to nut out how to make a decent one for my table saw and any other ideas could helpregards

Nick

veni, vidi, tornavi

Without wood it's just ...

-

20th February 2014, 06:25 PM #15

Similar Threads

-

Wadkin Morticer

By S Hayward in forum HAND TOOLS - POWEREDReplies: 2Last Post: 10th July 2020, 05:43 PM -

Wadkin PK makes FWW

By jgforsberg in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 3Last Post: 29th October 2012, 10:55 PM -

Wadkin RAS

By pmcgee in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 1Last Post: 5th October 2012, 09:52 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote